Preparation method of HFC-365mfc and HFC-245fa

A technology of hfc-245fa, cf3ch2-ccl2-ch3, applied in chemical instruments and methods, halogenated hydrocarbon preparation, halogen substitution preparation, etc., can solve problems such as unpublished methods, achieve high selectivity, excellent environmental protection performance, conversion high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

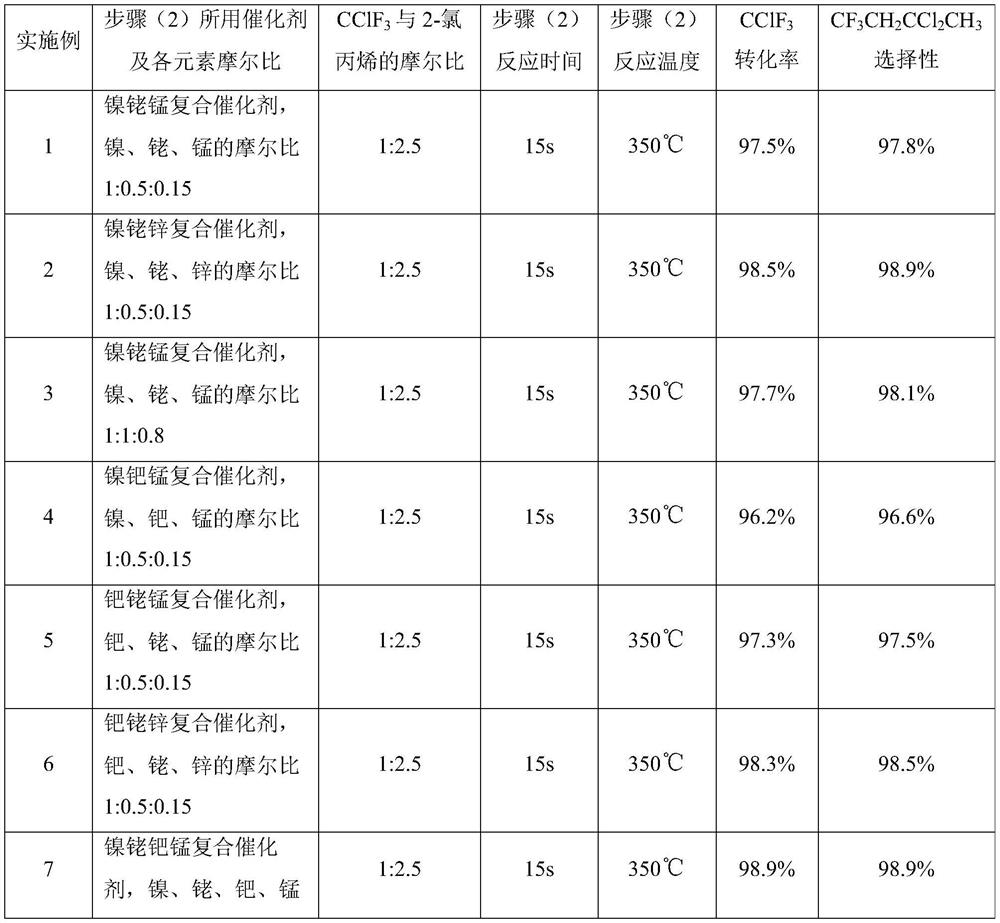

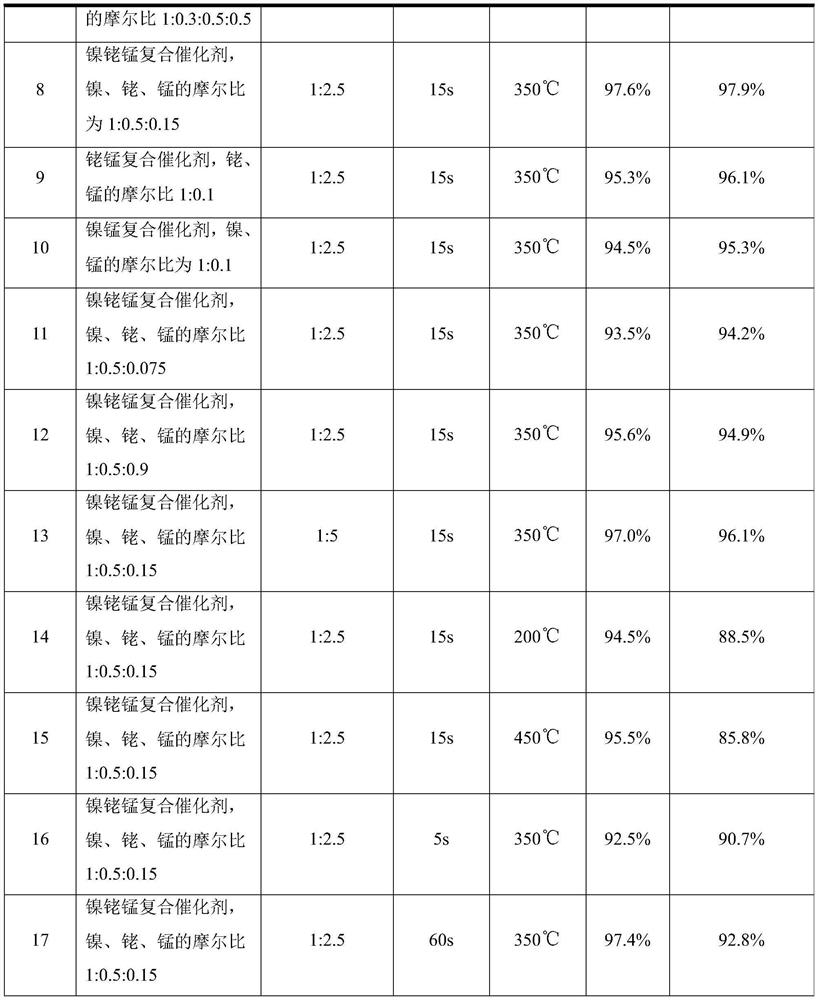

Examples

preparation example 1

[0063] Preparation of catalyst used in step (2) of the present invention.

[0064] Ni(NO 3 ) 2 ·6H 2 O, Rh (NO 3 ) 3 2H 2 O and Mn(NO 3 ) 2 ·6H 2 O, dissolved in 500ml of water, take 25% ammonia solution and add it dropwise to the above solution, control the pH value to 9, and at the same time turn on the magnetic stirring, centrifuge and dry, remove the lower layer of precipitate, dry at 120°C and bake at 450°C for 6h under nitrogen atmosphere Obtain nickel-rhodium-manganese composite catalyst, wherein the molar ratio of nickel, rhodium, and manganese is 1:0.5:0.15.

preparation example 2

[0066] Prepare the catalyst used in step (2) according to the method of Preparation Example 1, the difference is that Zn(NO 3 ) 2 ·6H 2 O instead of Mn(NO 3 ) 2 ·6H 2 O, the nickel-rhodium-zinc composite catalyst is prepared, wherein the mol ratio of nickel, rhodium, and zinc is 1:0.5:0.15.

preparation example 3

[0068] The catalyst used in step (2) was prepared according to the method of Preparation Example 1, except that the molar ratio of the prepared nickel, rhodium, and manganese was 1:1:0.8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com