Production process of cotton pulp for spinning-grade cellulose diacetate

A technology of cellulose diacetate and production process, which is applied in the direction of pulping of cellulose raw materials, post-processing of cellulose pulp, pulping with inorganic alkali, etc. requirements, the monopoly of the tobacco filter raw material market, and restrictions on the development of regenerated cellulose, to achieve the effects of stable polymerization degree, fast speed and high methyl fiber content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

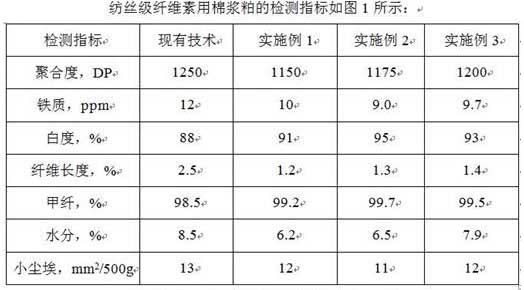

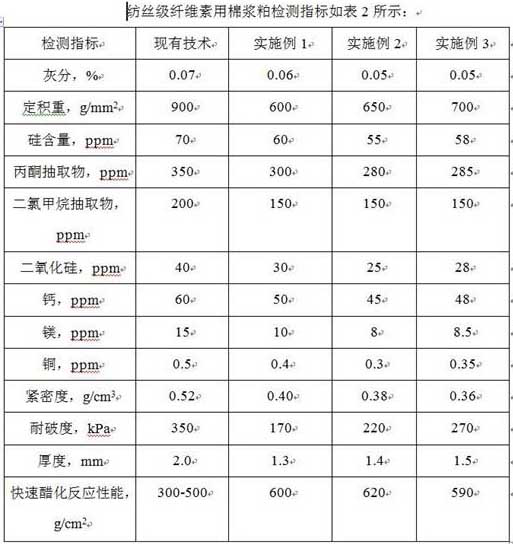

Examples

Embodiment 1

[0032] Embodiment 1: a kind of production technology of cotton pulp for spinning grade cellulose diacetate, specifically comprises the following steps:

[0033] 1) Material selection, cotton opening, and dry impurity removal: select 100% cotton linters with a maturity of 72% of the third category, and use a cotton opener to open the cotton linters. The opening thickness of the cotton linters is required to be ≤ 10cm, and put it into the cotton opener, the time of putting it into the cotton opener is ≥ 60min, and then send the cotton linters to the cleaning machine for selection and cleaning. The cotton linters of the miscellaneous machine are output in sequence, and sent to the screw through the cyclone separator for pressing.

[0034] 2) Alkali blending and impregnation: At a temperature of 60°C, the ratio of sodium hydroxide and water is 1:4.2. The concentration after alkali blending is required to be 45±2g / L. Before measuring the concentration of the alkali solution, it is ...

Embodiment 2

[0048] Embodiment 2: a kind of production technology of cotton pulp for spinning grade cellulose diacetate, specifically comprises the following steps:

[0049] 1) Material selection, cotton opening, and dry impurity removal: select 100% cotton linters with a maturity of 73% of the third category, and use an opener to open the cotton linters. The opening thickness of the cotton linters is required to be ≤ 10cm, and put it into the cotton opener, the time of putting it into the cotton opener is ≥ 60min, and then send the cotton linters to the cleaning machine for selection and cleaning. The cotton linters of the miscellaneous machine are output in sequence, and sent to the screw through the cyclone separator for pressing.

[0050] 2) Alkali blending and impregnation: At a temperature of 70°C, the ratio of sodium hydroxide and water is 1:4.4. The concentration after alkali blending is required to be 45±2g / L. Before measuring the concentration of the alkali solution, it is necess...

Embodiment 3

[0064] Embodiment 3: a kind of production technology of cotton pulp for spinning grade cellulose diacetate, specifically comprises the following steps:

[0065] 1) Material selection, cotton opening, and dry impurity removal: select 100% cotton linters with a maturity of 75% of the third category, and use a cotton opener to open the cotton linters. The opening thickness of the cotton linters is required to be ≤ 10cm, and put it into the cotton opener, the time of putting it into the cotton opener is ≥ 60min, and then send the cotton linters to the cleaning machine for selection and cleaning. The cotton linters of the miscellaneous machine are output in sequence, and sent to the screw through the cyclone separator for pressing.

[0066] 2) Alkali blending and impregnation: At a temperature of 60-80°C, the ratio of sodium hydroxide and water is 1:4.7. The concentration after alkali blending is required to be 45±2g / L. Before measuring the concentration of the alkali solution, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com