Metal negative electrode material and preparation method thereof

A metal anode and metal technology, applied in electrode manufacturing, battery electrodes, electrical components, etc., can solve problems such as unfavorable use of metal anode materials, and achieve the effects of inhibiting metal dendrite growth, stable structure, and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Such as Figure 1~Figure 3 As shown, the invention provides a kind of preparation method of metal negative electrode material, comprises the following steps:

[0029] dripping liquid mercury onto metal surfaces;

[0030] Wetting metal surfaces with liquid mercury;

[0031] After the liquid mercury reacts with the metal, a self-healing film containing amalgam is formed, thereby obtaining a metal negative electrode material.

[0032] In the embodiment of the present invention, a metal anode material containing an amalgam alloy layer with a dense structure and a uniform surface is prepared through an in-situ surface alloy reaction; the amalgam alloy layer effectively reduces the damage to the structure of the metal electrode itself caused by volume expansion during the cycle , and in the process of intercalating metal ions, a reversible phase transition occurs, which can better inhibit the growth of metal dendrites, prevent the direct reaction between the electrolyte and...

Embodiment 1

[0044] According to a certain mass ratio, use an electronic balance to weigh 1 part of amalgam, 1 part of solid electrolyte or 1 part of metal aluminum foil in the glove box, place the weighed aluminum foil and solid electrolyte in stainless steel trays, and drip with a glue head. The metal mercury is dropped onto the surface of metal or solid electrolyte, and after wetting the metal surface, a metal anode material containing amalgam film is obtained.

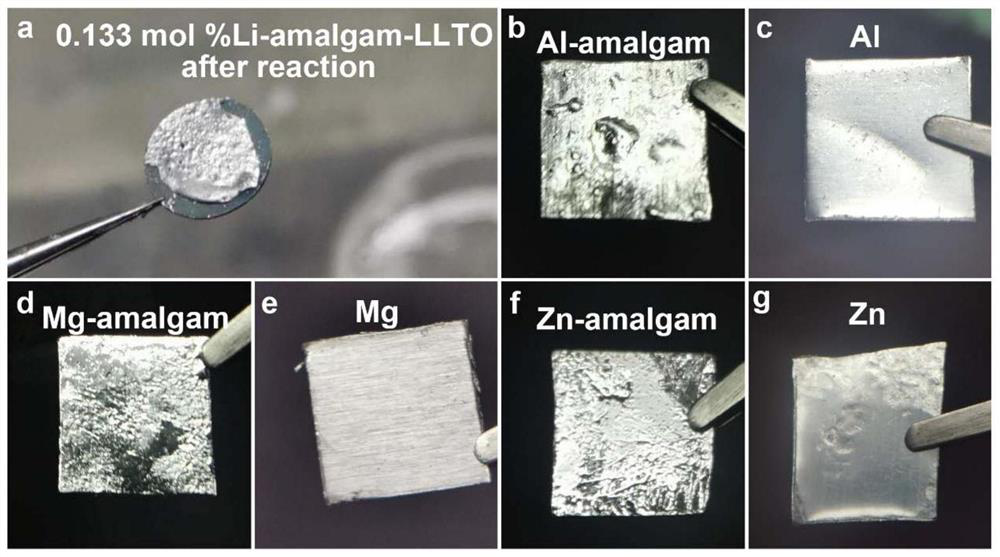

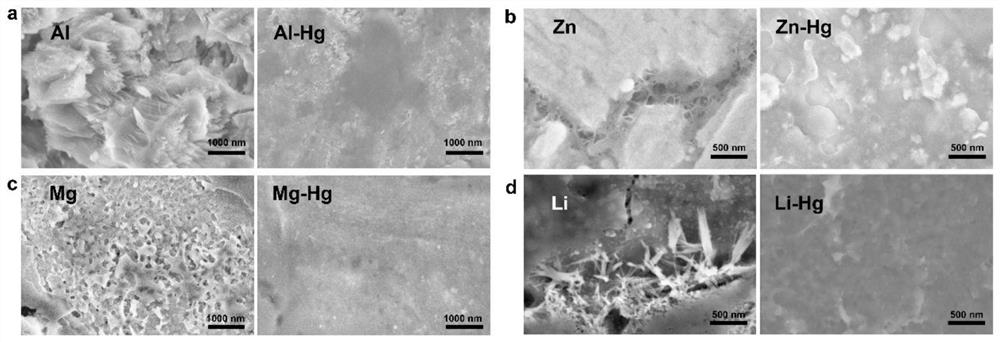

[0045] The present invention uses a Hitachi S-3400 (II) scanning electron microscope to observe the morphology of the material powder. Such as figure 1(a~c) in. It can be seen from the figure that the liquid amalgam can completely wet the surface of the solid electrolyte and the surface of metal aluminum, realizing the close combination of amalgam, solid electrolyte and metal aluminum, and the surface of the prepared amalgam film is flat and smooth.

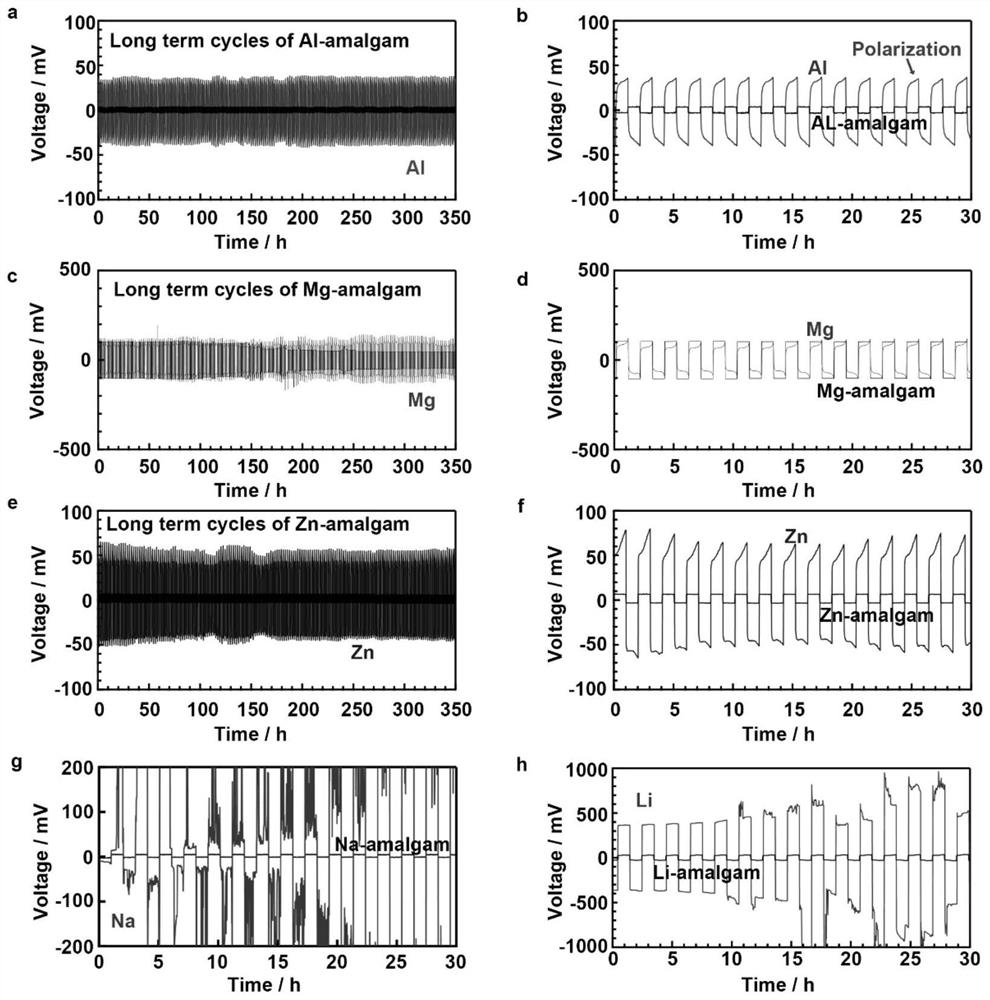

[0046] The invention uses a LAND battery test system to test the cycle volt...

Embodiment 2

[0048] According to a certain mass ratio, weigh 1 part of amalgam and 1 part of metal magnesium foil with an electronic balance in the glove box, place the weighed magnesium foil in a stainless steel tray, and drop the metal mercury onto the metal with a rubber dropper. After wetting the metal surface, a metal anode material containing amalgam film is obtained.

[0049] The present invention uses a Hitachi S-3400 (II) scanning electron microscope to observe the morphology of the material powder. Such as figure 1 (d, e) in . It can be seen from the figure that the liquid amalgam can completely wet the surface of metal magnesium, realize the close combination of amalgam and metal magnesium, and the surface of the prepared amalgam film is flat and smooth.

[0050] The invention uses a LAND battery test system to test the cycle voltage curve of the metal negative electrode material. The test results are shown in (c, d) in Figure 2. It can be seen from the figure that the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com