Carbon-based bio-enzyme fertilizer capable of resisting continuous cropping obstacles of flue-cured tobacco

A technology of continuous cropping obstacles and biological enzymes, applied in fertilization devices, fertilizer mixtures, agriculture, etc., can solve the problems of reduced enzyme activity related to soil carbon and nitrogen metabolism, imbalance of soil micro-ecological structure, and simplification of population changes, etc., to achieve enhanced air permeability , Loosening the soil and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of organic fertilizer:

[0023] The organic fertilizer is composed of 30% cow dung, 20% oil rot, 20% bacterial bag, 20% straw, and 10% phosphorus element, and add appropriate amount of Bacillus subtilis, Trichoderma, and actinomycetes at a temperature of 65-70°C and a humidity of 60°C Ferment for 20 days under the condition of -65% to get the special organic fertilizer for tobacco;

[0024] (2) Preparation of carbon-based biological enzyme fertilizer:

[0025] Use 45% of the organic fertilizer made above, mix the same amount of 45% biochar and 10% enzyme; after the biochar and organic fertilizer are evenly mixed, spray the enzyme with a spray method, and stir while spraying until uniform Mix and keep the temperature at 65-70°C and the humidity at 60-65% to ferment for 25 days to get the carbon-based bio-enzyme fertilizer.

Embodiment 2

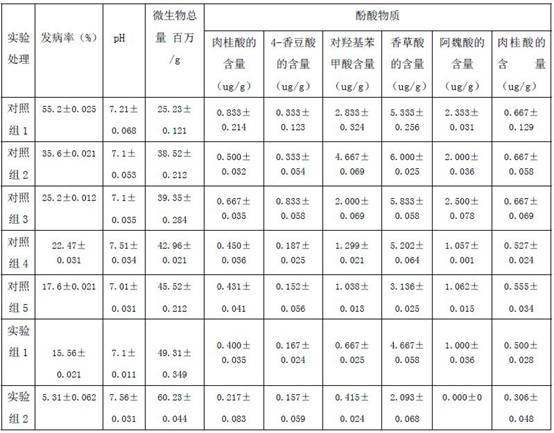

[0027] Control group 1: use common organic fertilizer as fertilizer, carry out continuous cropping flue-cured tobacco on the ground of planting flue-cured tobacco, and carry out corresponding data monitoring, take the average value;

[0028] Control group 2: use ordinary organic fertilizer as fertilizer, spray 10% of environmental protection enzymes, keep the temperature at 65-70°C and humidity at 60-65% for 25 days, and carry out continuous cropping of flue-cured tobacco on the ground where flue-cured tobacco has been planted. Above-mentioned fertilizer, and carry out corresponding data monitoring, take average value;

[0029] Control group 3: use ordinary organic fertilizer as fertilizer, and apply 0.1% of Bacillus subtilis, Trichoderma, and actinomycetes to carry out continuous cropping of flue-cured tobacco on the ground where flue-cured tobacco has been planted, apply the above fertilizer, and carry out corresponding data monitoring, and take the average value ;

[0030]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com