Equipment and method for synthesizing polyhydroxyalkanoate

A polyhydroxyalkanoate and equipment technology, which is applied in the field of polyhydroxyalkanoate synthesis, can solve the problems of large footprint, secondary pollution, and high operating costs, and achieve high reduction, high conversion rate, and economic additional high value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

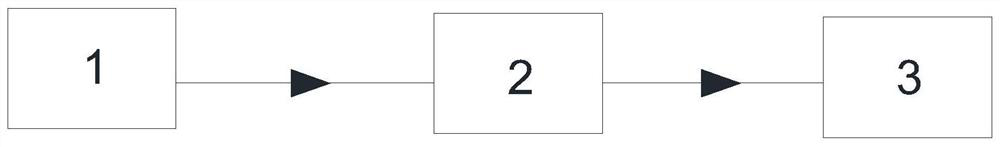

[0071] like figure 1 As shown, the present embodiment provides a kind of equipment for synthesizing polyhydroxyalkanoate, including: anaerobic acid generation device 1 for producing PHA synthetic raw material, PHA synthesis device 2 for synthesizing PHA and PHA extraction device for extracting PHA 3. The anaerobic acid generation device 1, the PHA synthesis device 2 and the PHA extraction device 3 are connected in sequence through pipelines.

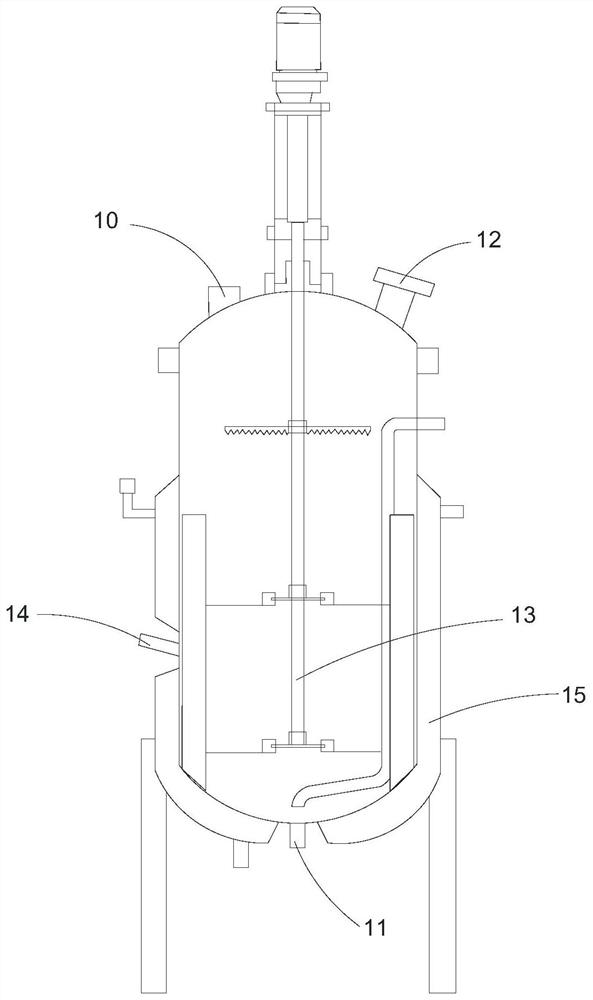

[0072] In a preferred embodiment, as figure 2 As shown, the anaerobic acid generation device 1 includes an anaerobic acid generation device body with accommodating space, and the anaerobic acid generation device body is provided with a feed port 10 for feeding, a discharge port 11 for discharging, Exhaust port 12 for exhaust; the inside of the anaerobic acid production device body is provided with a first stirring mechanism 13 for stirring and a first detection control part 14 (the first detection control part 14 includes the first det...

Embodiment 2

[0079] see Figure 4 , on the basis of Example 1, in order to better carry out anaerobic fermentation, while recovering the grease in the kitchen waste, in an optional embodiment, the equipment for synthesizing polyhydroxyalkanoate also includes The pulping device 4 for preparing kitchen waste into slurry and the oil-water separation device 5 for separating grease, the pulping device and the oil-water separation device are connected in sequence, and a delivery pump is arranged on the connecting pipeline, and the outlet of the oil-water separation device is connected to the anaerobic production line. The inlet of the acid unit is connected. The inside of the pulping device is equipped with a pulverizer for crushing and sorting food waste, and the solids are pulverized and screened to obtain particles of 3-4mm or less. The oil-water separation device includes an oil-water separation device body with accommodating space; the oil-water separation device body is provided with an o...

Embodiment 3

[0083] see Figure 5 , on the basis of Example 2, in order to better improve the efficiency of anaerobic fermentation, a filter device 6 for filtering large particles is also provided between the oil-water separation device 5 and the anaerobic acid production device 1; the outlet of the filter device 6 It communicates with the inlet of the anaerobic acid generating device 1.

[0084] In order to better homogenize the material and improve the stability of continuous production, in an optional embodiment, a first liquid storage homogenization device 7 is also arranged between the oil-water separation device 5 and the filtration device 6 . The first liquid storage homogenization device 7 is provided with a stirrer and a heater. The material in the first liquid storage and homogenization device 7 is input into the filter device 6 through a delivery pump.

[0085] In order to increase beneficial bacteria and treat municipal sludge, in an optional embodiment, the first liquid sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com