Spraying type colored asphalt, preparation method and use method thereof

A technology of colored asphalt and ester solvent, used in asphalt coatings, coatings, construction and other directions, can solve the problems of slow construction, high repair cost and high cost, and achieve the effects of convenient construction, repair of tiny cracks and low product viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

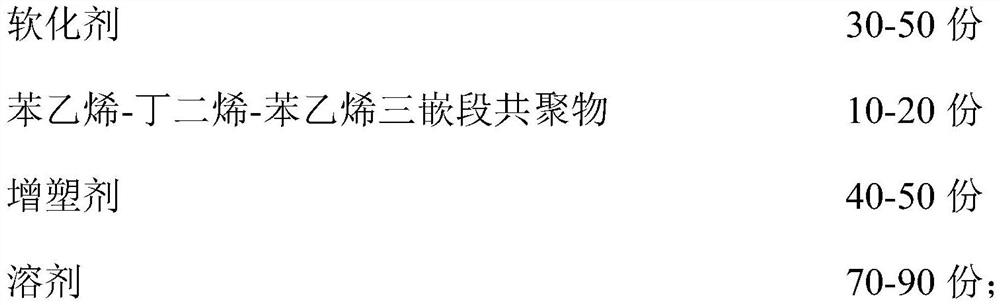

[0069] This embodiment provides a spray-type colored asphalt, the composition of raw materials is as follows:

[0070]

[0071] Spray type colored asphalt preparation method:

[0072] (1) Add the oil extracted from the third line and C5 petroleum resin into the asphalt modification tank, heat up to 160°C and stir for 1 hour to mix evenly, then heat up to 180°C and add SBS to cut, cut for 1.5 hours, keep the temperature constant, Add 1 part of toner, stir for 0.5h to mix evenly;

[0073] (2) Add ethyl acetate into the mixing tank, slowly add the melted colored asphalt into the mixing tank and keep stirring, the temperature is controlled at 40°C, stir for 2 hours to disperse evenly, then add No. 120 solvent naphtha and keep stirring, Control the temperature at 30°C, stir for 1 hour to disperse evenly;

[0074] (3) Add the dolomite powder into the uniformly dispersed solvent, stir and mix at room temperature for 0.5h to mix evenly, and prepare the spray-type colored asphalt....

Embodiment 2

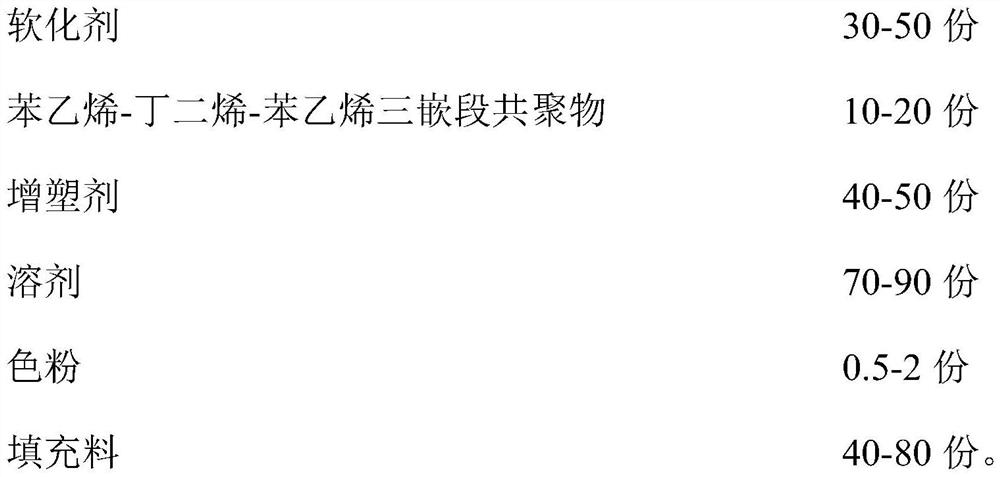

[0076] This embodiment provides a spray-type colored asphalt, the composition of raw materials is as follows:

[0077]

[0078] Spray type colored asphalt preparation method:

[0079] (1) Add the oil extracted from the third line and C5 petroleum resin into the asphalt modification tank, heat up to 160°C and stir for 1 hour to mix evenly, then heat up to 180°C and add SBS to cut, cut for 1.5 hours, keep the temperature constant, Add 1 part of toner, stir for 0.5h to mix evenly;

[0080] (2) Add methyl acetate into the mixing tank, slowly add the melted colored pitch into the mixing tank and keep stirring, the temperature is controlled at 40°C, stir for 2h to disperse evenly, then add cyclohexane and keep stirring, the temperature Control at 30°C, stir for 1 hour to disperse evenly;

[0081] (3) Add the limestone powder into the uniformly dispersed solvent, stir and mix at room temperature for 0.5h to mix evenly, and prepare the spray-type colored asphalt.

Embodiment 3

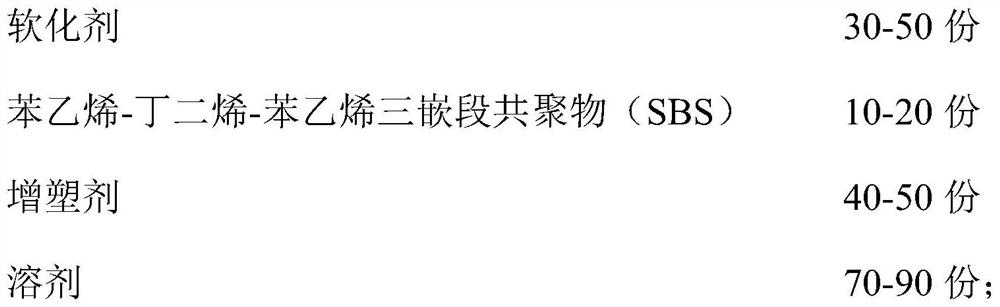

[0083] This embodiment provides a spray-type colored asphalt, the composition of raw materials is as follows:

[0084]

[0085]

[0086] Spray type colored asphalt preparation method:

[0087] (1) Add aromatic oil and C9 petroleum resin into the asphalt modification tank, heat up to 160°C and stir for 1 hour to mix evenly, then heat up to 180°C and add SBS to cut, cut for 1.5 hours, keep the temperature unchanged, add color 1 part of powder, stir for 0.5h to mix evenly;

[0088] (2) Add ethyl acetate into the mixing tank, slowly add the melted colored asphalt into the mixing tank and keep stirring, the temperature is controlled at 40°C, stir for 2 hours to disperse evenly, then add No. 140 solvent naphtha and keep stirring, Control the temperature at 30°C, stir for 1 hour to disperse evenly;

[0089] (3) Add talc powder and mineral powder into the uniformly dispersed solvent, stir and mix at room temperature for 0.5h to mix evenly, and prepare spray-type colored asphal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com