A kind of molybdenum-tungsten sputtering target material and preparation method thereof

A sputtering target, molybdenum-tungsten technology, applied in the field of powder metallurgy, can solve the problems of delamination or segregation, large density difference, affecting the uniformity of target structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

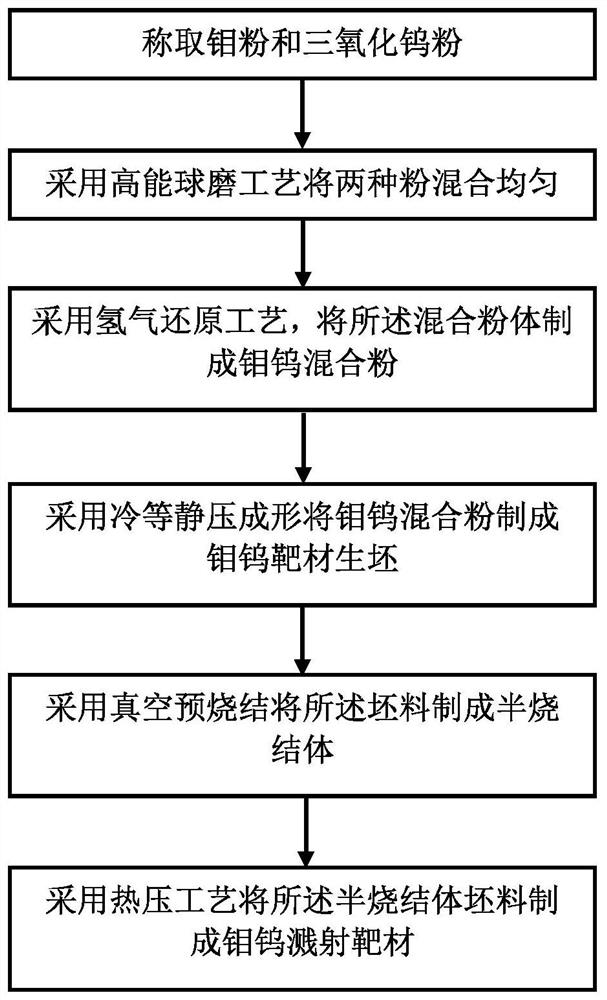

Method used

Image

Examples

Embodiment 1

[0036] 1) Weigh molybdenum powder with a particle size of 6.5 μm and a purity of ≥3N and tungsten trioxide powder with a particle size of 8 μm and a purity of ≥4N according to a mass fraction of tungsten trioxide of 20%;

[0037] 2) The mixture was prepared by high-energy ball milling process under Ar atmosphere, the speed of the ball mill was 110rpm, the mixing time was 18h, tungsten balls were used as the balls, and the ball-to-material ratio was 6:1;

[0038] 3) Put the mixed powder obtained in step 2) in a molybdenum boat, the powder thickness is 10mm, firstly carry out one-stage reduction at 480°C for 1h in a hydrogen furnace, and then carry out two-stage reduction at 920°C for 1.5h to obtain Molybdenum and tungsten mixed powder;

[0039] 4) The molybdenum-tungsten mixed powder obtained in step 3) is formed by cold isostatic pressing (CIP) to obtain a molybdenum-tungsten green body, the forming pressure is 180 MPa, and the holding time is 20 minutes;

[0040] 5) Place th...

Embodiment 2

[0044] 1) Weigh molybdenum powder with a particle size of 4.6 μm and a purity of ≥3N and tungsten trioxide powder with a particle size of 8.0 μm and a purity of ≥4N according to the mass fraction of tungsten trioxide of 15%;

[0045] 2) The mixture was prepared by high-energy ball milling process under vacuum atmosphere, the rotation speed of the ball mill was 120rpm, and the mixing time was 20h; molybdenum balls were used as grinding balls, and the ball-to-material ratio was 10:1;

[0046] 3) Place the mixed powder obtained in step 2) in a molybdenum boat with a powder thickness of 15mm. In a hydrogen furnace, firstly conduct a first-stage reduction at 460°C for 1.5h, and then conduct a second-stage reduction at 910°C for 1.2h. Obtain molybdenum-tungsten mixed powder;

[0047] 4) The molybdenum-tungsten mixed powder obtained in step 3) is formed by cold isostatic pressing (CIP) to obtain a molybdenum-tungsten green body, the forming pressure is 150 MPa, and the holding time i...

Embodiment 3

[0052] 1) Weigh molybdenum powder with a particle size of 5 μm and a purity of ≥3N and tungsten trioxide powder with a particle size of 8 μm and a purity of ≥4N according to a mass fraction of tungsten trioxide of 20%;

[0053] 2) The mixture was prepared by high-energy ball milling process under Ar atmosphere, the speed of the ball mill was 110rpm, the mixing time was 18h, tungsten balls were used as the balls, and the ball-to-material ratio was 6:1;

[0054] 3) Put the mixed powder obtained in step 2) in a molybdenum boat, the powder thickness is 10mm, firstly carry out one-stage reduction at 480°C for 1h in a hydrogen furnace, and then carry out two-stage reduction at 920°C for 1.5h to obtain Molybdenum and tungsten mixed powder;

[0055] 4) The molybdenum-tungsten mixed powder obtained in step 3) is formed by cold isostatic pressing (CIP) to obtain a molybdenum-tungsten green body, the forming pressure is 180MPa, and the holding time is 30min;

[0056] 5) Place the molybden...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com