Automatic shot indication and trajectory measurement system for relevant double-sampling linear array sensor

A line array sensor and correlated double sampling technology, applied in target indication system, measuring device, target, etc., can solve the problems of large structure, poor detection performance of high-speed projectiles, and unobvious dark spots, etc., to reduce data transmission Or the effect of processing pressure, detection accuracy higher than the target time, and simplifying the structure of software and hardware

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

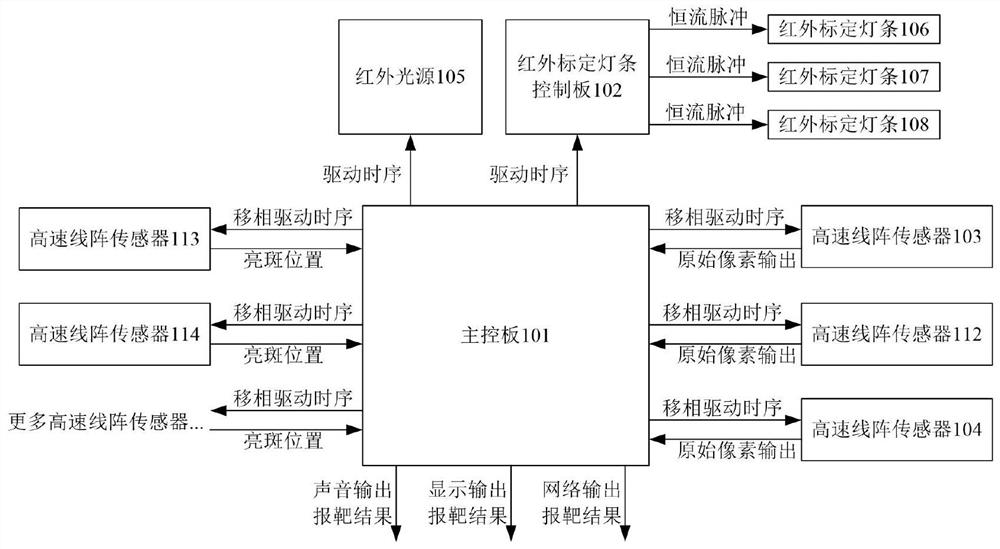

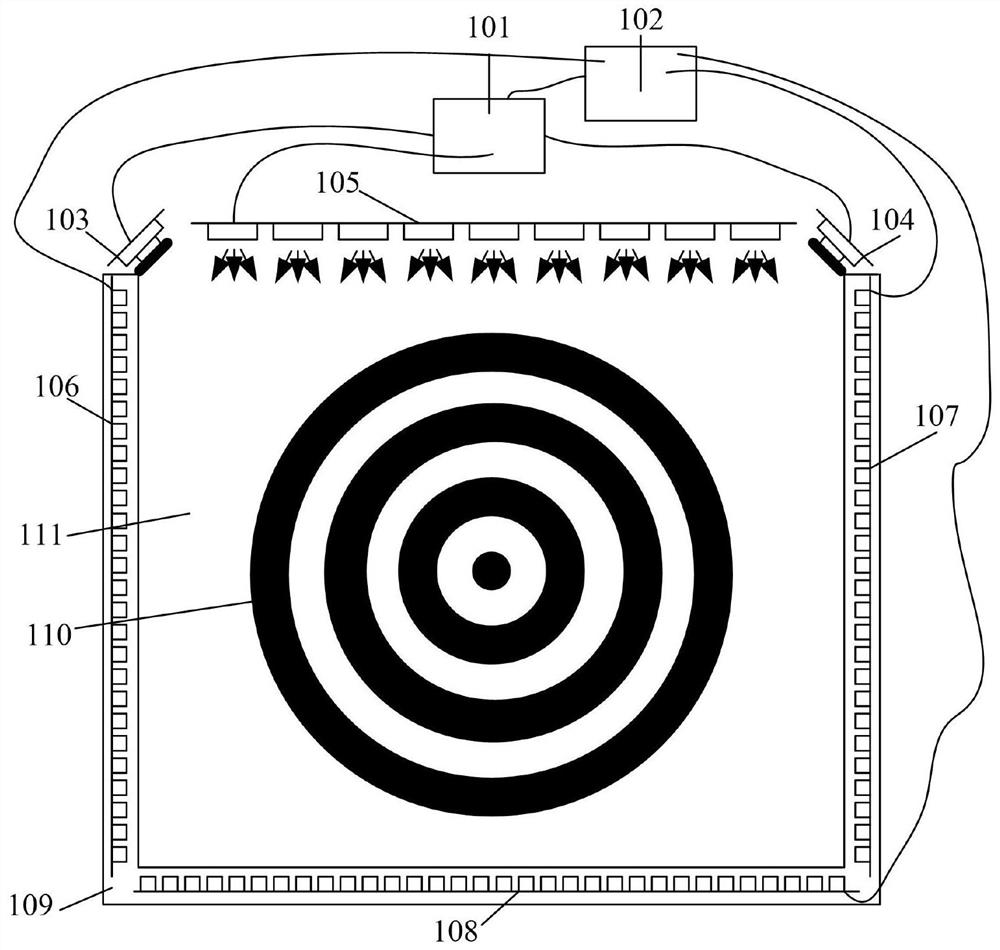

[0083] Compared with Embodiment 1, in addition to two high-speed line array sensors 103 and 104 installed on the sides other than the three side frames, embodiment 2 also adds a high-speed line array sensor 112, and the lens assembled by the sensor matches the angle of view of the sensor It is larger than 103 and 104, and it also needs to cover the target surface area. If a 2.3mm lens is used, a fan-shaped viewing angle range of not less than 122 degrees can be obtained, which is greater than 89 degrees of 103 and 104. In addition, the control timing of the three line array sensors in Embodiment 2 is also different from Embodiment 1. In Embodiment 1, 103 and 104 are as follows: Figure 4 As shown, the same control sequence is used, and in Embodiment 2, 103, 112, and 104 adopt a phase-shifted control sequence, so that at any moment, the non-exposure time of one sensor is covered by the exposure time of the other two sensors, that is Regardless of the moment when the projectile ...

Embodiment 1

[0093] Embodiment 1 and Embodiment 2 both only involve the positioning method of the coordinates of the projectile passing the target, and the method for measuring the moment of the projectile passing the target will be described below through Embodiment 3. Embodiment 3 also adopts the method of phase shifting, but compared with Embodiment 2, more high-speed line array sensors are used. The establishment method of the optical calibration table, the double-sampling CDS mode and the hardware selection method of the bright spot data in the third embodiment are the same as those in the first and second embodiments. Thanks to the method of selecting bright spot data by the hardware to reduce the pressure of data transmission and processing, embodiment 3 can use more high-speed linear array sensors to improve the measurement accuracy of the time when the projectile passes the target. For embodiment 3, in theory, when using n sensors, in the case of a high-speed projectile (the time ...

Embodiment 3

[0095] Embodiment 3 is described in detail below. The method of Embodiment 3 of the present invention is a method for detecting the position of the target and the moment of passing the target of various speed projectiles, comprising the following steps:

[0096] Step 1: The main control board controls the infrared light source to be turned off, and the infrared calibration light bar control board is used to control the infrared calibration light bar to light up chain by chain, that is, each light chain is turned off after multiple scanning cycles, and the output of the main control board is shifted. Drive the logic to N>3 high-speed line array sensors, but only collect the images of each light chain sequentially lit by 3 of the sensors that return the original pixel output. The phase shift phase of the original pixel acquisition sensor must be guaranteed, The non-exposure time of any high-speed line array sensor among the three sensors that return the original pixel output is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com