High-brightness LED and preparation method thereof

A technology with high brightness and doping concentration, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of complicated high-brightness LED preparation process, difficult control of substrate polishing and thinning process, lack of high-brightness LED, etc., to achieve epitaxy The effect of shortening process time, shortening epitaxy process time, and improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

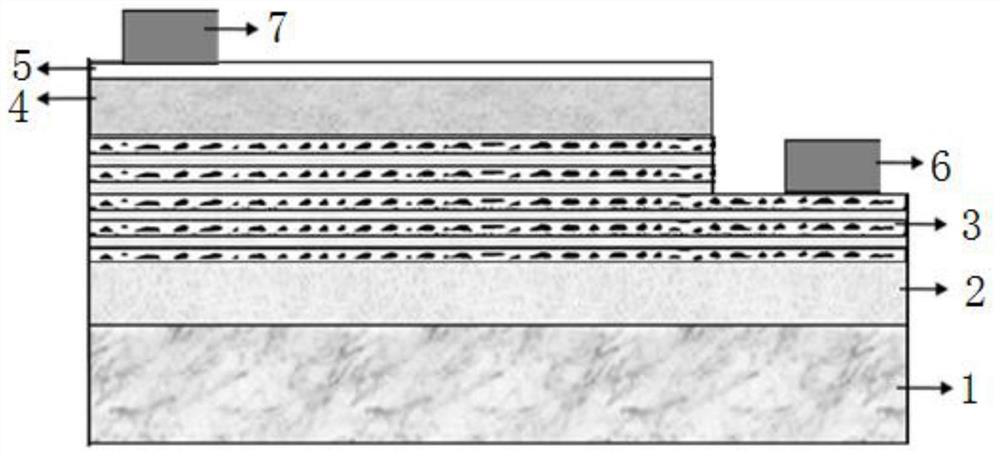

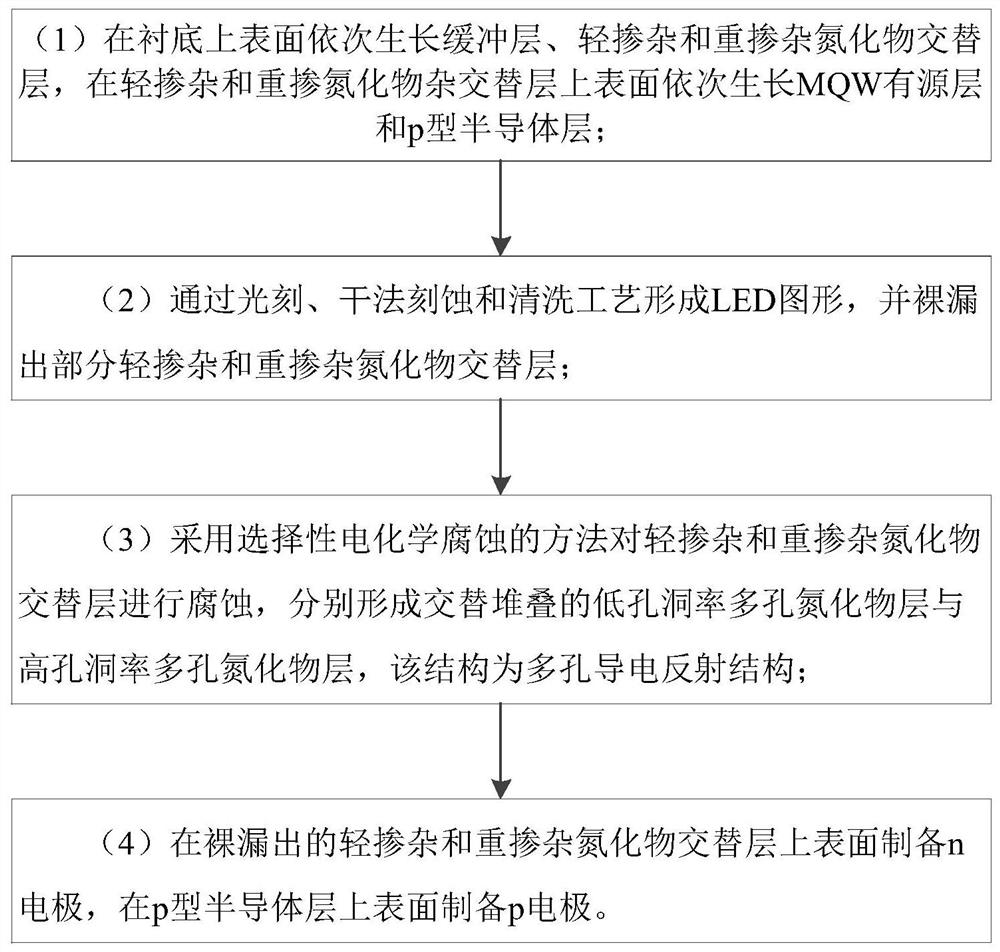

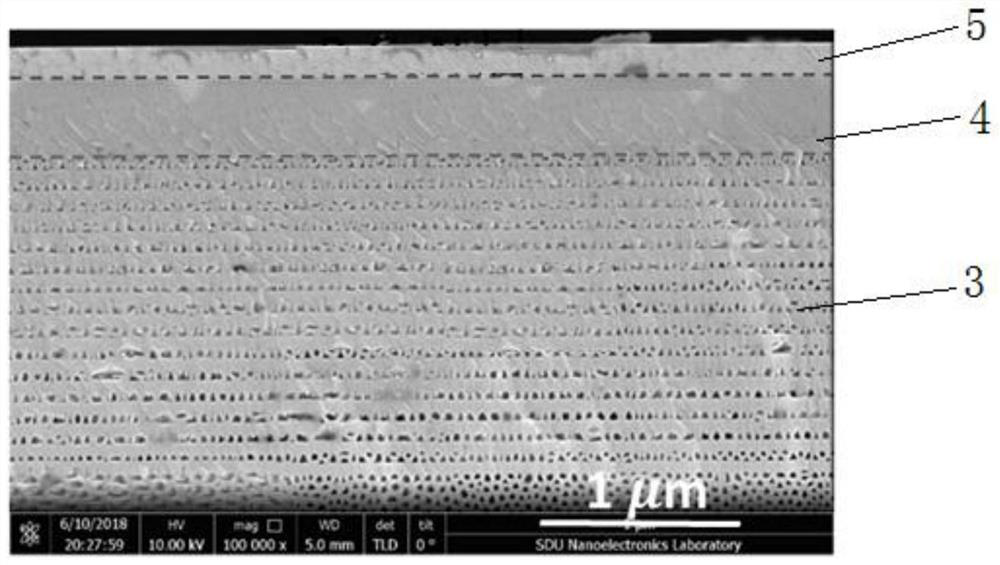

[0034] The invention provides a high brightness LED, such as figure 1 As shown, it includes a substrate 1, on which a buffer layer 2, lightly doped and heavily doped nitride alternating layers 3, MQW active layer 4, and p-type semiconductor layer 5 are sequentially grown, lightly doped and heavily doped An n-electrode 6 is provided on the exposed part of the upper surface of the alternating heteronitride layer 3, and a p-electrode 7 is provided on the p-type semiconductor layer 5; as image 3 As shown, the lightly doped and heavily doped nitride alternating layers 3 are alternately stacked low-porosity porous nitride layers and high-porosity porous nitride layers formed by lightly doped nitride layers and heavily doped nitride layers respectively by electrochemical corrosion. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Doping concentration | aaaaa | aaaaa |

| Doping concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com