A current collector and its preparation method and application

A fluid-collecting and integrated technology, which is applied in the direction of electrode carriers/collectors, non-aqueous electrolyte battery electrodes, structural parts, etc., can solve problems such as bad, difficult to weld, and affect the actual promotion and application of composite current collectors, so as to save production costs , reduce the internal resistance, and avoid the effect of increasing the impedance of the welding point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] The current collector of this embodiment is prepared according to the following method:

[0088] Take two rolls of metal foil (aluminum foil with a thickness of 2 μm), wash the two rolls of metal foil with 0.001g / L phosphoric acid solution for 5 minutes, then wash with 0.001g / L sodium hydroxide solution for 5 minutes, and then wash with deionized water for 1 minute , and finally washed with dimethyl carbonate for 1 min and dried in the air.

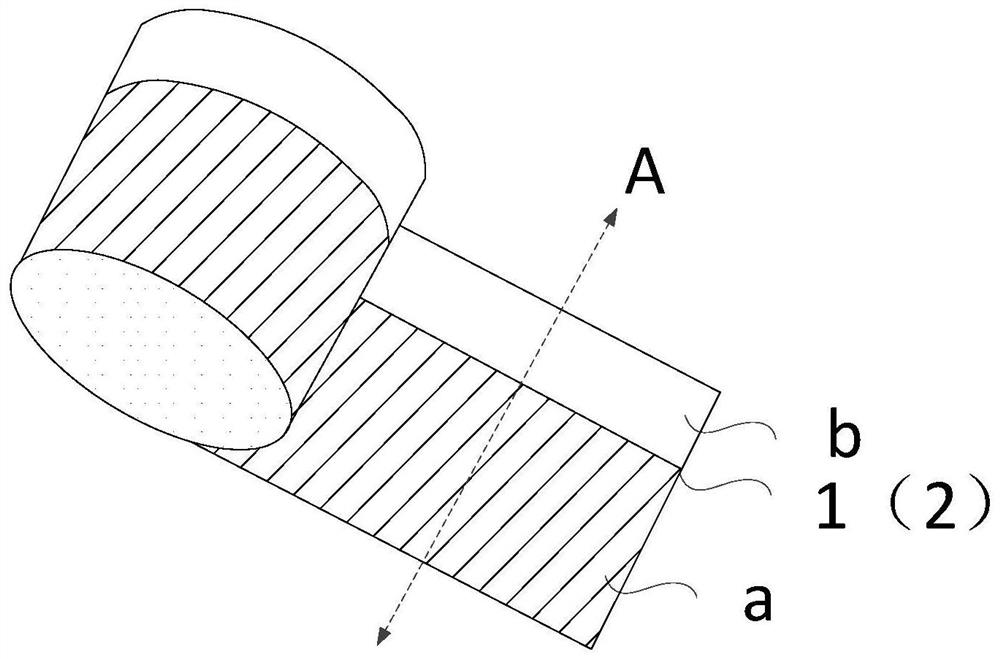

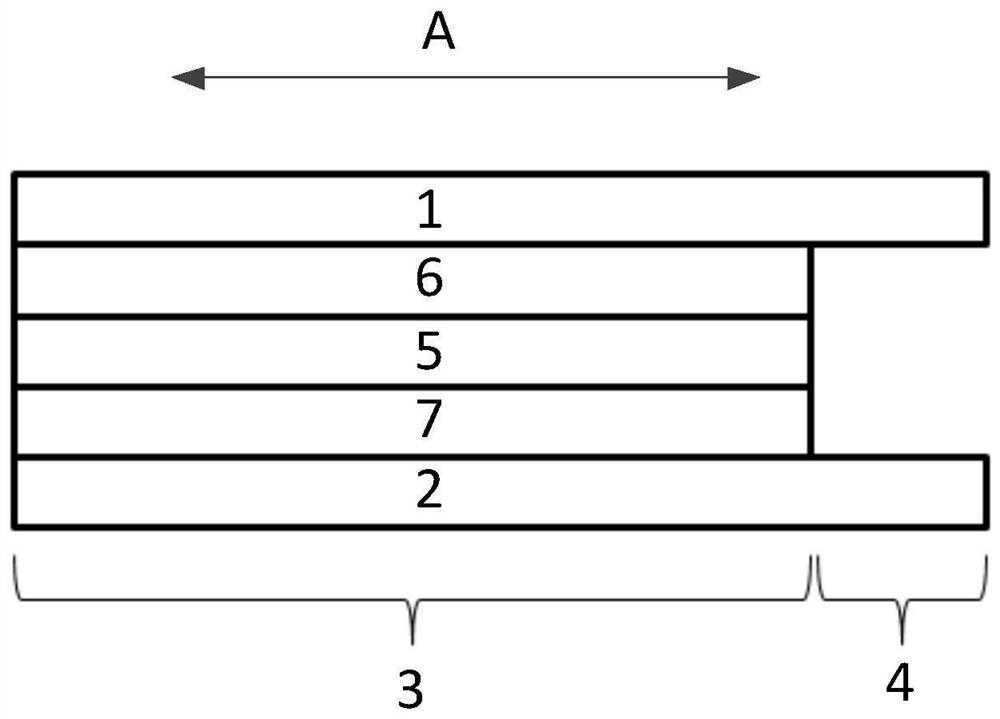

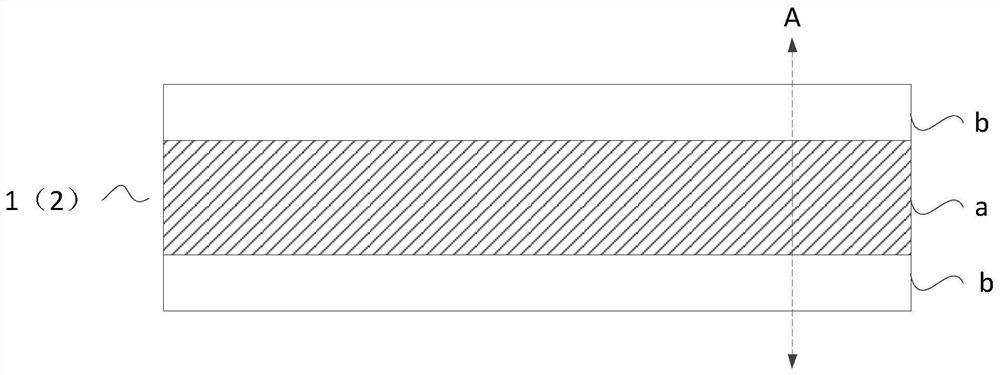

[0089] Take one of the rolls of pretreated metal foil, by controlling the coated area, use a coater to apply a coating machine on the first area 3 of the metal foil (the first area 3 and the second area 4 are along the extending direction of the metal foil) distribution in the vertical direction) corresponding to the surface coated with the first adhesive layer 6 (polyurethane adhesive with a thickness of 0.1 μm, Wuxi Bo’ai Adhesive Factory), through an extrusion casting compound machine (the extrusion temperature of the equipment ...

Embodiment 2

[0094] The current collector of this embodiment is prepared according to the following method:

[0095] Take two rolls of metal foil (aluminum foil with a thickness of 3 μm), wash the two rolls of metal foil with 0.5g / L phosphoric acid solution for 0.5min, then wash with 0.5g / L sodium hydroxide solution for 0.5min, and then pass through deionized water Wash for 30 minutes, and finally wash with acetone for 30 minutes and dry in air.

[0096] Take one of the rolls of pretreated metal foil, and by controlling the coated area, use a coater to spread the metal foil between the first area and the first area (the first area and the second area are along the direction perpendicular to the extending direction of the metal foil) Distribution) corresponding to the surface coated with the first adhesive layer (polyurethane adhesive with a thickness of 1 μm, Wuxi Boai Adhesive Factory), through the extrusion casting compound machine (equipment extrusion temperature is set to 284 ° C) in the...

Embodiment 3

[0100] The current collector of this embodiment is prepared according to the following method:

[0101] Take two rolls of metal foil (aluminum foil with a thickness of 1 μm), wash the two rolls of metal foil with 0.1g / L phosphoric acid solution for 1min, then wash with 0.1g / L sodium hydroxide solution for 1min, and then wash with deionized water for 10min , and finally washed with absolute ethanol for 10 min, and dried in the air.

[0102] Take one of the rolls of pretreated metal foil, and by controlling the coated area, use a coater to spread the metal foil between the first area and the first area (the first area and the second area are along the direction perpendicular to the extending direction of the metal foil) distribution) corresponding to the surface coated with the first adhesive layer (polyacrylic resin adhesive with a thickness of 0.5 μm, Wuxi Bo’ai Adhesive Factory), and passed through the extrusion casting compound machine (the extrusion temperature of the equip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com