A kind of preparation method of multifunctional stone-paper-based flowerpot

A stone paper, multi-functional technology, applied in the fields of botanical equipment and methods, chemical instruments and methods, substrate fertilizer, etc. The effect of protecting external damage, good growth environment and high aesthetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

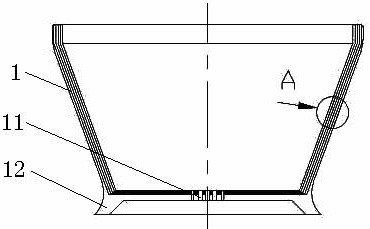

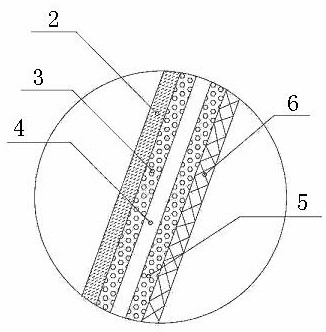

[0097] The flowerpot structure provided by the present invention is such as figure 1 , figure 2 , wherein: 1 is the basin with cavity, 11 is the drainage hole at the bottom of the basin, 12 is the bottom of the basin, and the basin 1 is composed of the following layers: 2 is the controlled release layer on the inner surface, 3 is the subsurface As for the slow-release thermal insulation layer, 4 is the functional layer in the middle, 5 is the external slow-release thermal insulation layer, and 6 is the outer surface layer.

Embodiment 2

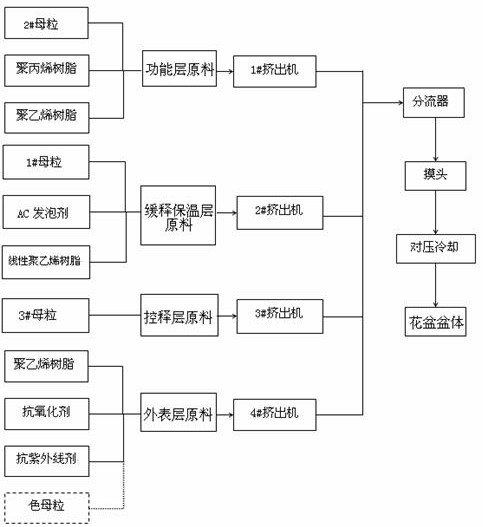

[0099] The flowerpot of the present invention is made by the following steps:

[0100] 1) Preparation of 1# masterbatch of slow-release insulation layer raw materials

[0101] 1A) Prepare materials according to the following mass ratios:

[0102] 800-1200 mesh calcium carbonate powder: 70%

[0103] Aluminate coupling agent: 2%

[0104] Polypropylene: 20%

[0105] Stearic acid: 1%

[0106] Paraffin: 2%

[0107] Ethylene-vinyl acetate copolymer EVA: 5%;

[0108] 1B) Stir the calcium carbonate powder of step 1A) at 110 °C for 5 minutes at a speed of 650 r / min, then add the aluminate coupling agent, stir and mix at a speed of 650 r / min for 3 minutes, and finally add additives and polypropylene, mixed and stirred for 8 minutes at a speed of 1380r / min at 120°C to obtain a mixture;

[0109] 1C) Put the mixture in step 1B) into the internal mixer, and at a temperature of 185 ° C, banbury for 10 min to obtain a banbury;

[0110] 1D) The Banbury product of step 1C) is fed into t...

Embodiment 3

[0163] The flower pot body of the present invention is obtained by the following steps:

[0164] 1) Preparation of 1# masterbatch of slow-release insulation layer raw materials

[0165] 1A) Prepare materials according to the following mass ratios:

[0166] 800-1200 mesh calcium carbonate powder: 39%

[0167] Aluminate coupling agent: 1%

[0168] Polypropylene: 50%

[0169] Stearic acid: 2%

[0170] Paraffin: 7%

[0171] Ethylene-vinyl acetate copolymer EVA: 1%;

[0172] 1B) Stir the calcium carbonate powder of step 1A) at 90 °C for 3 minutes at a speed of 800 r / min, then add the aluminate coupling agent, stir and mix at a speed of 800 r / min for 3 minutes, and finally add the auxiliary agent and polypropylene, at 150°C for 10 minutes at a speed of 1200r / min, to obtain a mixture;

[0173] 1C) Put the mixture in step 1B) into the internal mixer, and at 150 ° C, mix for 15 minutes to obtain the internal compound;

[0174] 1D) The Banbury product of step 1C) is sent to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com