Yogurt having antioxidant functions and preparation method thereof

An anti-oxidation and production method technology, which is applied to milk preparations, bacteria used in food preparation, dairy products, etc., can solve the problems of poor growth of Lactobacillus plantarum, improve superoxide anion scavenging ability, and sticky texture Silky, hydroxyl radical scavenging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

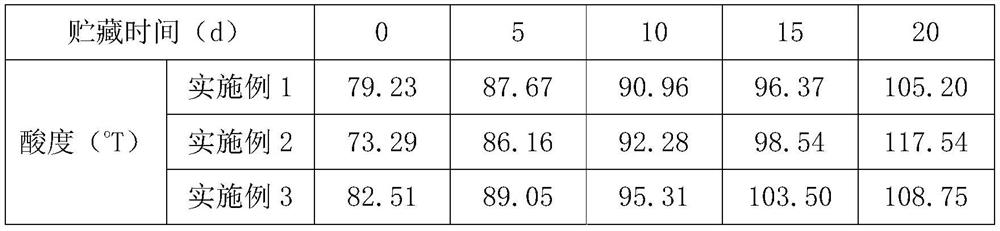

Embodiment 1

[0055] A method for preparing yoghurt with antioxidant function, comprising the following steps:

[0056] (1) Preparation of reconstituted milk: Weigh 100 g of skim milk powder and 900 g of water to prepare reconstituted milk, and then heat the reconstituted milk to 60° C. Based on the mass of the reconstituted milk, 6% sucrose and 1% whey protein powder were added respectively, followed by stirring and mixing at 200 r / min for 20 min.

[0057] (2) Homogenization: Homogenize the reduced milk with a homogenizer at 60° C. for 3 minutes, and the homogenization pressure is 20 MPa.

[0058] (3) Sterilization: sterilize the homogenized feed solution in a water bath at 90°C for 10 minutes, and then rapidly cool to 37°C.

[0059] (4) Enzymatic hydrolysis: Add trypsin at a rate of 2 mg of enzyme per 100 g of reconstituted milk, and hydrolyze at 37° C. for 20 min.

[0060] (5) Enzyme inactivation: Immediately after hydrolysis, heat in a water bath at 100°C for 5 minutes, quickly cool t...

Embodiment 2

[0065] A method for preparing yoghurt with antioxidant function, comprising the following steps:

[0066] (1) Preparation of reconstituted milk: Weigh 110 g of skim milk powder and 850 g of water to prepare reconstituted milk, and heat to 55° C. Based on the mass of the reconstituted milk, 5% sucrose and 0.5% whey protein powder were added, followed by stirring and mixing at 200 r / min for 20 min.

[0067] (2) Homogenization: Homogenize the reconstituted milk with a homogenizer at 60° C. for 3 minutes, with a pressure of 20 MPa.

[0068] (3) Sterilization: Sterilize the homogenized feed solution in a water bath at 85°C for 30 minutes, and then rapidly cool it to 37°C.

[0069] (4) Enzymatic hydrolysis: Add trypsin at a rate of 3 mg of enzyme per 100 g of reconstituted milk, and hydrolyze at 37° C. for 25 minutes.

[0070] (5) Enzyme inactivation: Immediately after hydrolysis, heat in a water bath at 95°C for 7 minutes, rapidly cool to 42°C, and keep warm until use.

[0071] ...

Embodiment 3

[0075] A method for preparing yoghurt with antioxidant function, comprising the following steps:

[0076] (1) Preparation of reconstituted milk: weigh 90 g of skim milk powder and 1000 g of water to prepare reconstituted milk, and heat to 60° C. Based on the mass of the reconstituted milk, 9% sucrose and 2% whey protein powder were added, followed by stirring and mixing at 200 r / min for 20 min.

[0077] (2) Homogenization: Homogenize the reconstituted milk with a homogenizer at 65° C. for 5 minutes at a pressure of 25 MPa.

[0078] (3) Sterilization: sterilize the homogenized feed solution in a water bath at 95°C for 5 minutes, and then rapidly cool to 40°C.

[0079] (4) Enzymatic hydrolysis: Add trypsin at a ratio of 2 mg of enzyme per 100 g of reconstituted milk, and hydrolyze at 40° C. for 20 min.

[0080] (5) Enzyme inactivation: Immediately after hydrolysis, heat in a water bath at 100°C for 5 minutes, quickly cool to 38°C, and keep warm until use.

[0081] (6) Inoculu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com