Steak preparation process

A preparation process and steak technology, applied in food science and other directions, can solve problems such as limited improvement, and achieve the effects of improving tenderness, reducing moisture loss and good marinating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

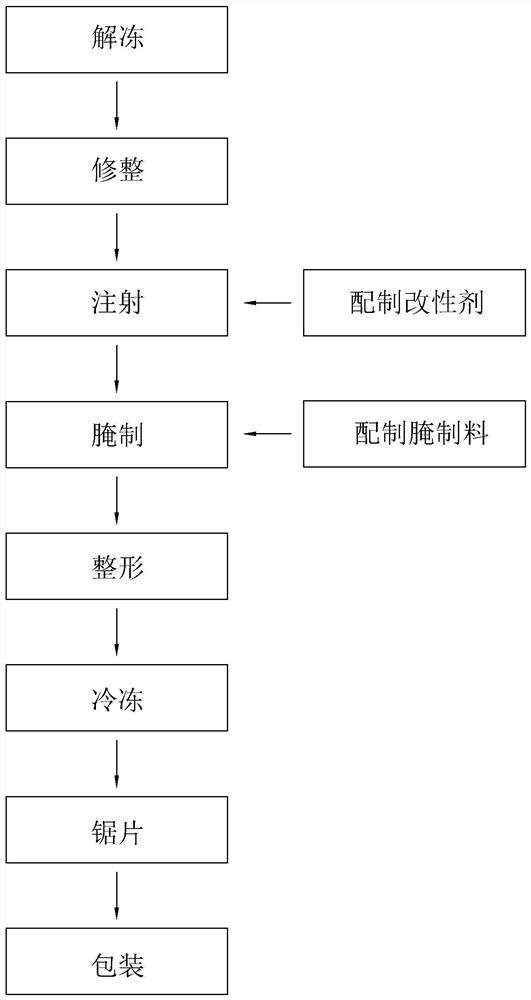

[0066] Such as figure 1 Shown, a kind of preparation technology of steak comprises the following steps:

[0067] S1, thawing: thawing the prepared beef;

[0068] S2, trimming: remove the fascia and excess fat on the surface of the beef, and cut the beef into required sizes;

[0069] S3, injection: inject modifier to beef through injection machine;

[0070] S4, marinating: Put the injected beef and marinade into a vacuum tumbler for tumbling and marinating, the temperature is 0-4°C, the vacuum degree is <-0.7bar, the speed is 10r / min, and each tumbling is 20min , standing for 10min, the total time is 2h;

[0071] S5, shaping: shaping the rolled and kneaded beef;

[0072] S6, freezing: putting the shaped beef into the freezer for freezing until hard;

[0073] S7, Saw blade: Saw the frozen beef and cut it into the final sale size;

[0074] S8, Packing: Vacuum pack the sawed beef and beef, quick-freeze, pack and store.

[0075] In parts by weight, in every 500g of beef, the...

Embodiment 2

[0078] A preparation process for steak, comprising the following steps:

[0079] S1, thawing: thawing the prepared beef;

[0080] S2, trimming: remove the fascia and excess fat on the surface of the beef, and cut the beef into required sizes;

[0081] S3, injection: inject modifier to beef through injection machine;

[0082] S4, marinating: Put the injected beef and marinade into a vacuum tumbler for tumbling and marinating, the temperature is 0-4°C, the vacuum degree is <-0.7bar, the speed is 10r / min, and the total time is 80min ;

[0083] S5, shaping: shaping the rolled and kneaded beef;

[0084] S6, freezing: putting the shaped beef into the freezer for freezing until hard;

[0085] S7, Saw blade: Saw the frozen beef and cut it into the final sale size;

[0086] S8, Packing: Vacuum pack the sawed beef and beef, quick-freeze, pack and store.

[0087] In parts by weight, in every 500g of beef, the components of the modifier are shown in Table 1, and the components of th...

Embodiment 3

[0090] A steak preparation process, the difference from Example 1 is that, by weight, in every 500g of beef, the components of the modifier are shown in Table 1, and the components of the marinade are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com