Denture stabilizing sealant and preparation method thereof

A sealant, stable technology, used in dental preparations, pharmaceutical formulations, medical science, etc., can solve the problems of short bond strength time and reduced bond performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

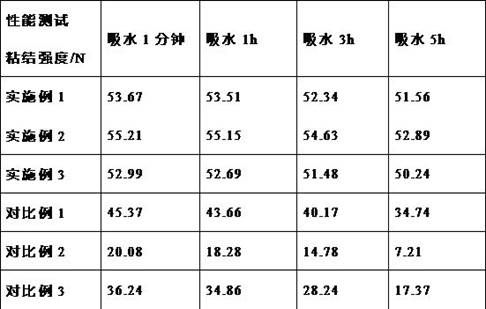

Examples

Embodiment 1

[0025] A denture stabilization sealant prepared as follows:

[0026] Get 20 mass parts of liquid paraffin, 30 mass parts of vaseline, heat in a water bath to melt and mix uniformly, then mix 30 mass parts of polyvinyl methyl ether / maleic anhydride calcium sodium mixed salt (calcium The total sodium substitution rate is 50%), 50 parts by mass of hydroxyethyl cellulose, 15 parts by mass of NCO-terminated polyethylene glycol and isophorone diisocyanate prepolymer, 1 part by mass of silicon dioxide, 0.1 parts by mass The pigment and 0.5 parts by mass of menthol are added to the carrier, and stirred continuously, and cooled to room temperature after stirring evenly.

[0027]Among them, the prepolymer of NCO-terminated polyethylene glycol and isophorone diisocyanate is obtained by vacuum-drying 10 parts by mass of polyethylene glycol (molecular weight 1000) at 100°C for 3 hours to remove water, and cooling to 70°C 50 parts by mass of isophorone diisocyanate and 0.05 parts by mass o...

Embodiment 2

[0029] A denture stabilization sealant prepared as follows:

[0030] Get 20 mass parts of liquid paraffin, 30 mass parts of vaseline, heat in a water bath to melt and mix uniformly, then add 40 mass parts of polyvinyl methyl ether / maleic anhydride calcium sodium mixed salt (calcium The total sodium substitution rate is 50%), 50 parts by mass of hydroxyethyl cellulose, 20 parts by mass of NCO-terminated polyethylene glycol and isophorone diisocyanate prepolymer, 1 part by mass of silicon dioxide, 0.1 parts by mass The pigment and 0.5 parts by mass of menthol are added to the carrier, and stirred continuously, and cooled to room temperature after stirring evenly.

[0031] Wherein, the prepolymer of NCO-terminated polyethylene glycol and isophorone diisocyanate is prepared by the method in Example 1.

Embodiment 3

[0033] A denture stabilization sealant prepared as follows:

[0034] Get 20 mass parts of liquid paraffin, 30 mass parts of vaseline, heat in a water bath to melt and mix uniformly, then mix 30 mass parts of polyvinyl methyl ether / maleic anhydride calcium sodium mixed salt (calcium The total sodium substitution rate is 60%), 40 parts by mass of hydroxyethyl cellulose, 15 parts by mass of NCO-terminated polyethylene glycol and isophorone diisocyanate prepolymer, 1 part by mass of silicon dioxide, 0.1 parts by mass The pigment and 0.5 parts by mass of menthol are added to the carrier, and stirred continuously, and cooled to room temperature after stirring evenly.

[0035] Wherein, the prepolymer of NCO-terminated polyethylene glycol and isophorone diisocyanate is prepared by the method in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com