Mechanical vapor recompression drying system and method

A technology of mechanical steam and drying system, applied in chemical instruments and methods, dewatering/drying/concentrating sludge treatment, special treatment targets, etc. Small, low moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

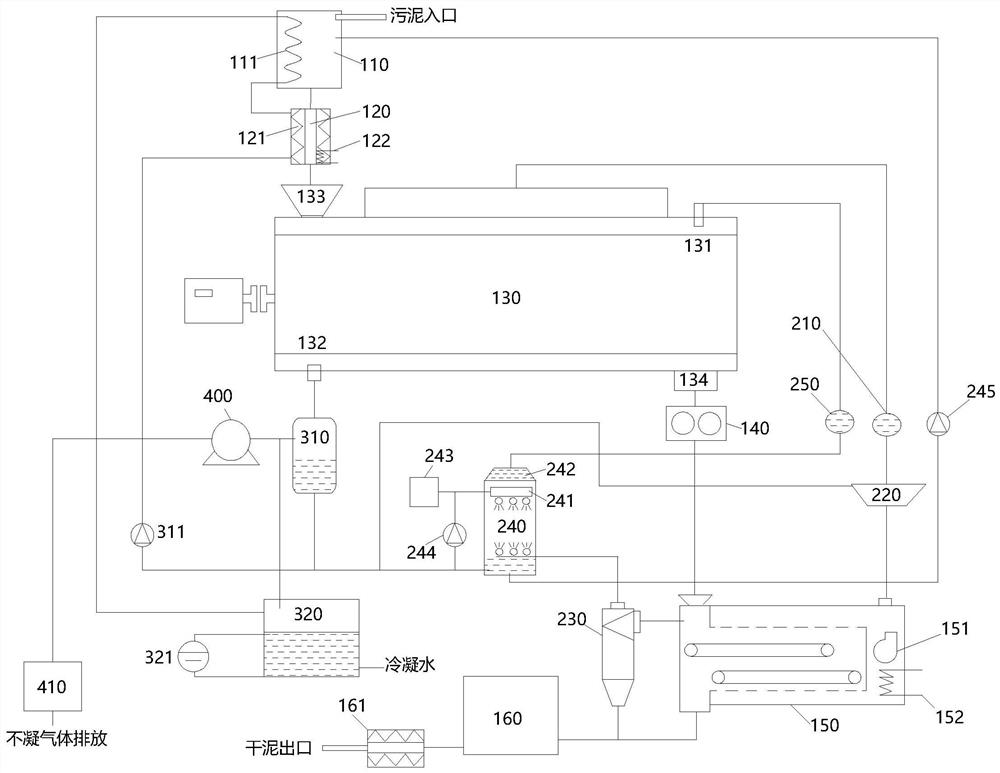

[0045] Such as figure 1 , the present invention provides a first embodiment of a mechanical vapor recompression drying system, which includes a sludge storage tank 110 that stores normal temperature sludge incoming materials and has a condensed water heat exchange coil 111 inside, and an output of the sludge storage tank 110 The sludge injection pump 120 connected with the jacketed heat exchanger 121 and the first external heat source heater 122, the thin-layer evaporative dryer 130 connected with the output of the sludge injection pump 120, and the output of the thin-layer evaporative dryer 130 Connected extrusion slitting molding machine 140, the mesh belt drier 150 that links to each other with the output of extrusion slitting molding machine 140, the dry mud bin 160 that links to each other with the output of mesh belt drier 150, is arranged on thin layer evaporative drier 130 and The steam compressor 220 between the mesh belt dryers 150, the cyclone dust collector 230 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com