Super-hydrophilic high-wear-resistance film layer and preparation method thereof

A super-hydrophilic, film-layer technology, which is applied in the direction of coating, metal material coating process, vacuum evaporation plating, etc., can solve the problem of super-hydrophilic film surface roughness, low wear resistance, large water contact angle, etc. problems, to achieve the effect of good compactness, strong anti-wear performance, and strong mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

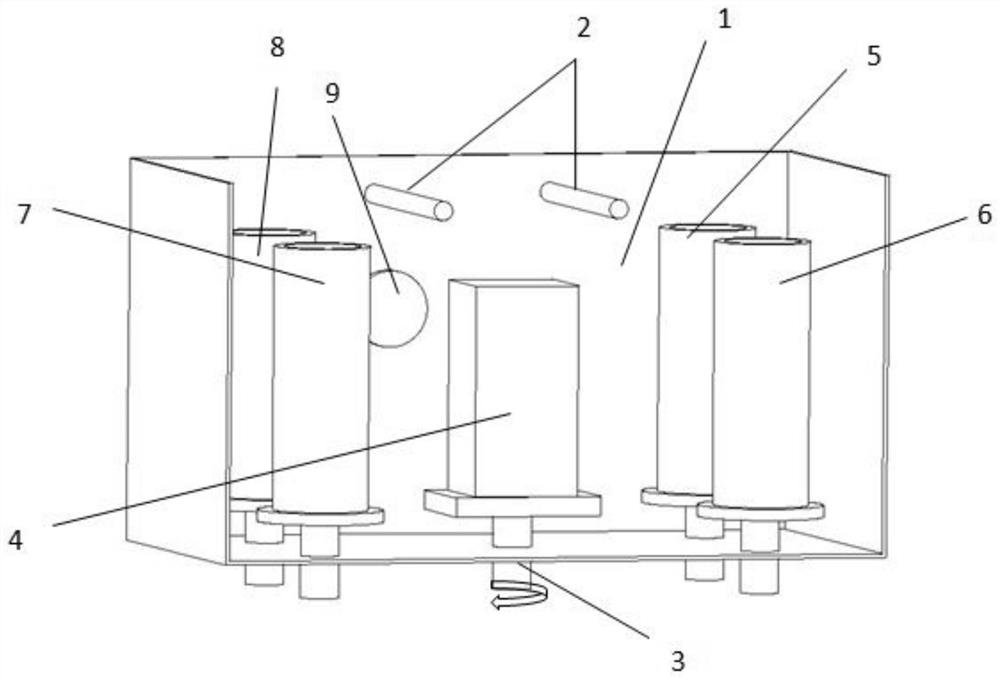

Image

Examples

Embodiment 1

[0032] This embodiment provides a method for preparing a super-hydrophilic, highly wear-resistant film, comprising the following steps:

[0033] (1) Immerse the ultra-clear glass substrate in absolute alcohol for 10 minutes of ultrasonic cleaning, and then dry it at an ambient temperature of 60°C to obtain a glass substrate, and then put the glass substrate into a magnetron sputtering coating equipment for vacuum On the sample holder in the chamber, the sample holder is located on the upper part of the sample holder rotating table, which has a rotating function and can ensure the uniformity of the film layer during the coating process;

[0034](2) A high-purity Si target with a purity of 99.99% was prepared by a vacuum plasma thermal spraying method, and TiO with a purity of 99.9% was prepared by a plasma thermal spraying method 2 The target material is a SnSb alloy target material with an antimony content of 2% prepared by melting and casting method, and a conductive ZrO with...

Embodiment 2

[0039] This embodiment provides a method for preparing a super-hydrophilic, highly wear-resistant film, comprising the following steps:

[0040] (1) Immerse the ultra-clear glass substrate in absolute alcohol for 8 minutes of ultrasonic cleaning, and then dry it at an ambient temperature of 50°C to obtain a glass substrate, and then put the glass substrate into a magnetron sputtering coating equipment for vacuum On the sample holder in the chamber, the sample holder is located on the upper part of the sample holder rotating table, which can ensure the uniformity of the film layer during the coating process;

[0041] (2) A high-purity Si target with a purity of 99.99% was prepared by a vacuum plasma thermal spraying method, and TiO with a purity of 99.9% was prepared by a plasma thermal spraying method 2 The target material is a SnSb alloy target material with an antimony content of 20% prepared by melting and casting method, and a conductive ZrO with a purity of 99.9% is prepa...

Embodiment 3

[0046] This embodiment provides a method for preparing a super-hydrophilic, highly wear-resistant film, comprising the following steps:

[0047] (1) Soak the ultra-clear glass substrate in absolute alcohol for 9 minutes, then dry it at 55°C to obtain a glass substrate, and then put the glass substrate into a magnetron sputtering coating equipment for vacuum On the sample holder in the chamber, the sample holder is located on the upper part of the sample holder rotating table, which can ensure the uniformity of the film layer during the coating process;

[0048] (2) A high-purity Si target with a purity of 99.99% was prepared by a vacuum plasma thermal spraying method, and TiO with a purity of 99.9% was prepared by a plasma thermal spraying method 2 The target material is a SnSb alloy target material with an antimony content of 10% prepared by melting and casting method, and a conductive ZrO with a purity of 99.9% is prepared by plasma spraying method x The target material cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com