Phosphogypsum pretreatment and purification method

A phosphogypsum and pretreatment technology, applied in the field of phosphogypsum purification, can solve the problems of aggravating the loss of water-soluble phosphorus and fluorine, unable to build gypsum, environmental pollution, etc., and achieve the effects of reducing product consumption, prolonging the initial setting time, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

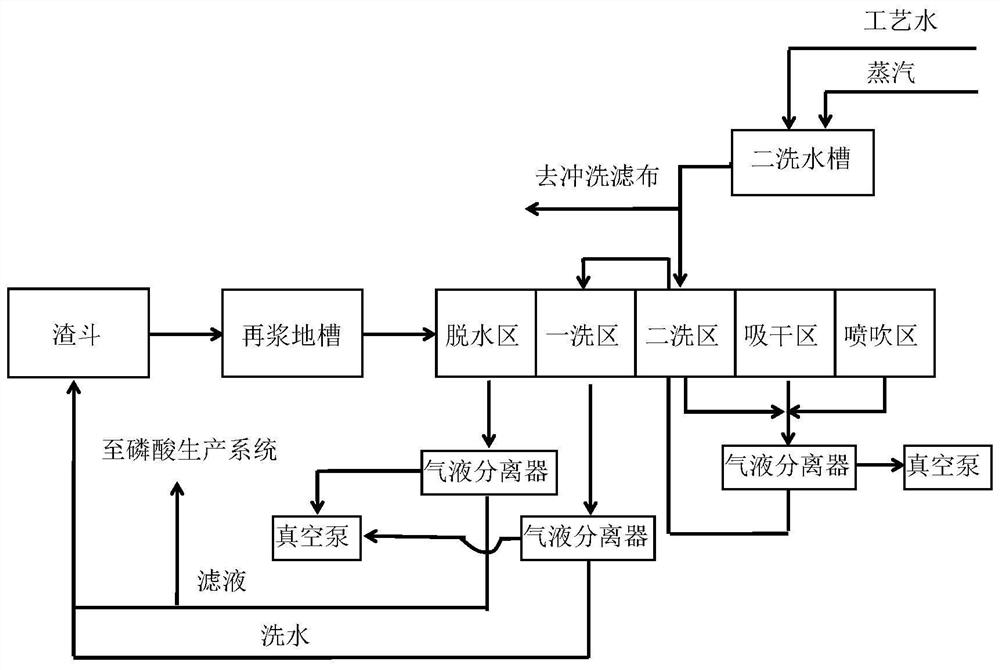

[0023] After the phosphogypsum is unloaded into the slag hopper, use the phosphogypsum pretreated washing water and part of the filtrate to return to rinse and re-slurry. The gypsum slurry enters the gypsum re-slurry tank and stirs evenly to control the slurry concentration to 31%. The repulped slurry is pumped to the slurry distribution box of the belt filter and evenly distributed, and then dehydrated in the dehydration zone.

[0024] The vacuum degree of the filter is controlled by two vacuum pumps, the absolute pressure of the dehydration and washing area is 35kPa, and the absolute pressure of the other area is 30kPa.

[0025] Gypsum adopts two-stage countercurrent washing. The water in the washing tank is heated by steam, and the water temperature is 65°C. The washing water pump is sent to the secondary washing water distribution box to wash the gypsum evenly. The lotion after the second washing is pumped as the first-level gypsum. The washing water and the washing liquid...

Embodiment 2

[0029] After the phosphogypsum is unloaded into the slag hopper, use the phosphogypsum pretreated washing water and part of the filtrate to return to rinse and re-slurry. The gypsum slurry enters the gypsum re-slurry tank and stirs evenly to control the slurry concentration to 32%. The repulped slurry is pumped to the slurry distribution box of the belt filter and evenly distributed, and then dehydrated in the dehydration zone.

[0030] The vacuum degree of the filter is controlled by two vacuum pumps, the absolute pressure of the dehydration and washing area is 35kPa, and the absolute pressure of the other area is 30kPa.

[0031] Gypsum adopts two-stage countercurrent washing. The water in the washing tank is heated by steam, and the water temperature is 65°C. The washing water pump is sent to the secondary washing water distribution box to wash the gypsum evenly. The lotion after the second washing is pumped as the first-level gypsum. The washing water and the washing liquid...

Embodiment 3

[0035] After the phosphogypsum is unloaded into the slag hopper, use the phosphogypsum pretreated washing water and part of the filtrate to return to rinse and re-slurry. The gypsum slurry enters the gypsum re-slurry tank, stirs evenly, and controls the slurry concentration to 35%. The repulped slurry is pumped to the slurry distribution box of the belt filter and evenly distributed, and then dehydrated in the dehydration zone.

[0036] The vacuum degree of the filter is controlled by two vacuum pumps respectively, the absolute pressure of the dehydration and washing area is 31kPa, and the absolute pressure of the other area is 27kPa.

[0037] Gypsum adopts two-stage countercurrent washing. The water in the washing tank is heated by steam, and the water temperature is 70°C. The washing water pump is sent to the secondary washing water distribution box to wash the gypsum evenly. The lotion after the second washing is pumped as the first-level gypsum. The washing water and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com