Production and preparation method of polycarboxylate superplasticizer powder

A technology of water reducing agent and polycarboxylic acid, which is applied in the field of production and preparation of polycarboxylate water reducing agent powder, can solve the problems of drop in electrokinetic potential, insufficient adsorption capacity, influence on construction of workers, etc. The effect of strong practicability and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

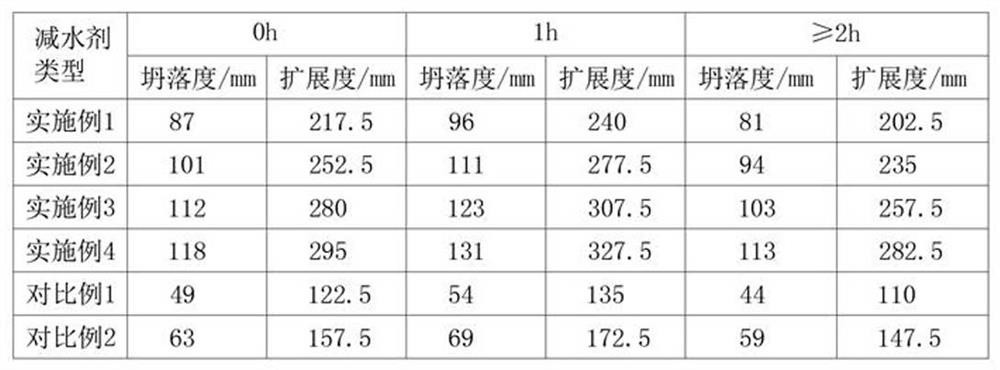

[0028] see Figure 1-3 , the present invention provides a technical solution: a method for producing a polycarboxylate water reducer powder, the polycarboxylate water reducer comprises the following raw materials by weight: 30.2% to 41% of water, prenyl alcohol Polyoxyethylene 30%~34%, hydrogen peroxide solution 1.8%~2.1%, acrylic acid solution 4.2%~4.7%, third mixed solution 10%~13%, sodium hydroxide solution 13%~16%;

[0029] The production and preparation method of the polycarboxylate superplasticizer powder comprises the following steps:

[0030] Step 1. Add 30.2%-41% water, 30%-34% isoprenol polyoxyethylene ether, 1.8%-2.1% hydrogen peroxide solution in the reaction kettle, and then start stirring, during the stirring process The reaction kettle is heated to 55 ℃~65 ℃ to obtain the first mixed solution, and the temperature inside the reaction kettle is kept at 55 ℃~65 ℃;

[0031] Step 2, dropping 4.2%~4.7% acrylic acid solution into the first mixed solution at a uniform...

Embodiment 1

[0043] Example 1: as figure 2 , image 3 , add 41% of water, 30% of isoprenol polyoxyethylene ether, 1.8% of hydrogen peroxide solution in the reaction kettle, then start stirring, and in the process of stirring, the reaction kettle is heated to 55 ℃ ~ 65 ℃ , obtain the first mixed solution, keep the temperature inside the reactor at 55 ℃~65 ℃, drop 4.2% acrylic acid solution into the first mixed solution at a uniform speed, obtain the second mixed solution, and make the inside of the reactor The temperature is maintained at 55 ℃~65 ℃, and 10% of the third mixed solution is dropped into the second mixed solution at an even rate to obtain the fourth mixed solution with a pH value of 4, and the interior of the reactor is kept at 55 ℃~65 ℃. One hour, then reduced to 15 ° C ~ 40 ° C, 13% of sodium hydroxide was added to the fourth mixed solution and fully stirred to obtain a fifth mixed solution with a pH value of 6, and then the polycarboxylate was prepared as described above. ...

Embodiment 2

[0044] Example 2: as figure 2 , image 3 , add 36.7% of water, 32% of isopentenol polyoxyethylene ether, 1.9% of hydrogen peroxide solution in the reaction kettle, then start stirring, and the reaction kettle is heated to 55 ℃~65 ℃ in the process of stirring , obtain the first mixed solution, keep the temperature inside the reactor at 55 ℃ ~ 65 ℃, drop 4.4% acrylic acid solution into the first mixed solution at a uniform speed, obtain the second mixed solution, and make the inside of the reactor The temperature is maintained at 55 ℃~65 ℃, and 11% of the third mixed solution is dropped into the second mixed solution at an even rate to obtain the fourth mixed solution with a pH value of 4, and the interior of the reactor is kept at 55 ℃~65 ℃. One hour, and then reduced to 15 ℃ ~ 40 ℃, 14% of sodium hydroxide was added to the fourth mixed solution and fully stirred to obtain a fifth mixed solution with a pH value of 6.3, and then the polycarboxylate was prepared in the manner d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com