Composition for forming undercoat layer of energy storage device

A technology of undercoating and composition, which is applied in the field of composition for undercoating, can solve problems such as lack of clear understanding and low resistance of batteries, and achieve low resistance and suppress the rise of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

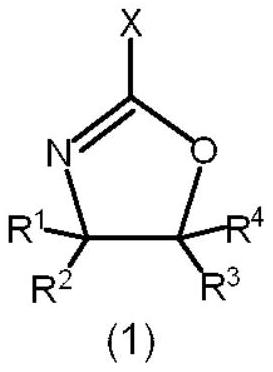

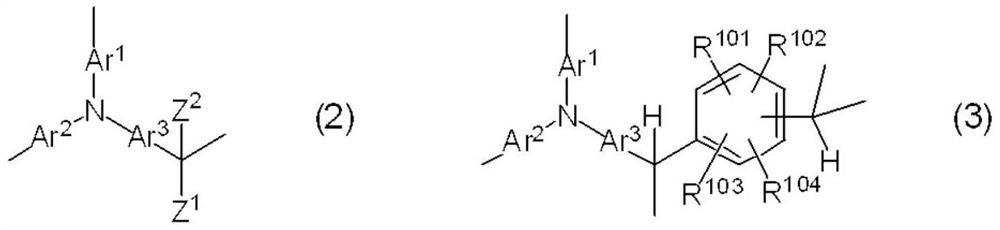

[0254] EPOCROS WS-300 (manufactured by Nippon Shokubai Co., Ltd.), which is an aqueous solution containing an oxazoline polymer as a dispersant, has a solid content concentration of 10% by mass and a weight average molecular weight of 1.2×10 5 , oxazoline group amount 7.7mmol / g) 5.0g, pure water 37.15g and 2-propanol (manufactured by Junsei Chemical Co., Ltd., reagent special grade) 7.35g were mixed, and TC as a conductive carbon material was mixed therein -2010 (manufactured by Toda Kogyo Co., Ltd., multilayer CNT) 0.5 g. The obtained mixture was subjected to ultrasonic treatment for 30 minutes using a probe-type ultrasonic irradiation device to prepare a dispersion liquid in which the conductive carbon material was uniformly dispersed. Mixed into it as containing polyammonium acrylate (PAA-NH 4 ) of an aqueous solution of ARON A-30 (Toagosei Co., Ltd., solid content concentration 31.6% by mass) 1.2 g, 41.35 g of pure water, and 7.44 g of 2-propanol (manufactured by Junsei C...

Embodiment 2-1

[0268] Using a wire bar coater (OSP-13, wet film thickness 13 μm), the primer solution of Example 1-1 was evenly spread on an aluminum foil (thickness 15 μm) as a current collector, and dried at 150° C. for 30 minutes. An undercoat layer was formed to produce an undercoat foil.

[0269] Prepare 20 pieces of bottom-coated foils and cut them into 5×10cm products. After measuring the mass, measure the paper soaked in a 1:1 (mass ratio) mixture of 2-propanol and water to wipe off the bottom coating. The mass of the metal foil, the weight per unit area of the primer layer calculated from the mass difference before and after wiping off is 150mg / m 2 .

[0270] 31.84 g of lithium iron phosphate (LFP, manufactured by Aleees Co., Ltd.) as an active material, and an NMP solution of polyvinylidene fluoride (PVdF) as a binder (12% by mass, Kureha, KF POLYMER L#1120) 13.05 g, 1.39 g of DENKA BLACK as a conductive material, and 13.72 g of N-methylpyrrolidone (NMP) were mixed for 1 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com