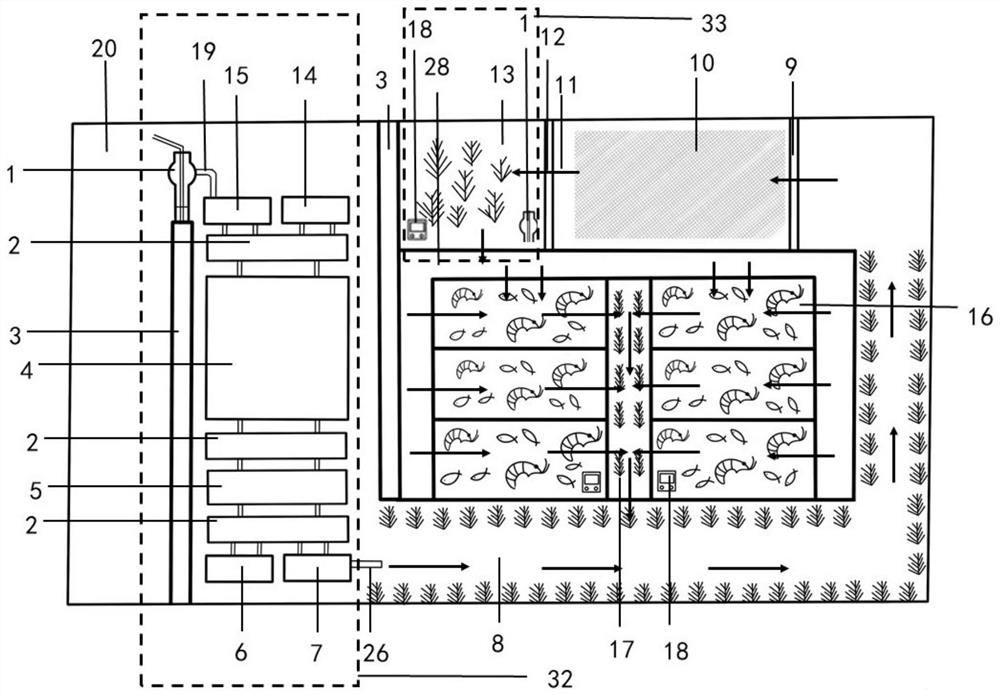

Purification system for integrated culture of fishes and shrimps

A purification system, fish and shrimp technology, applied in the field of comprehensive fish and shrimp purification system, can solve the problems of inability to remove pollution, pollution, environmental pollution, etc., and achieve the effect of improving ecological efficiency, reducing environmental pollution, and reducing the probability of disease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] The above-mentioned breeding mode was used to carry out breeding experiments in the Yancheng Science and Technology Experiment Demonstration Base of Jiangsu Province. The specific breeding methods include:

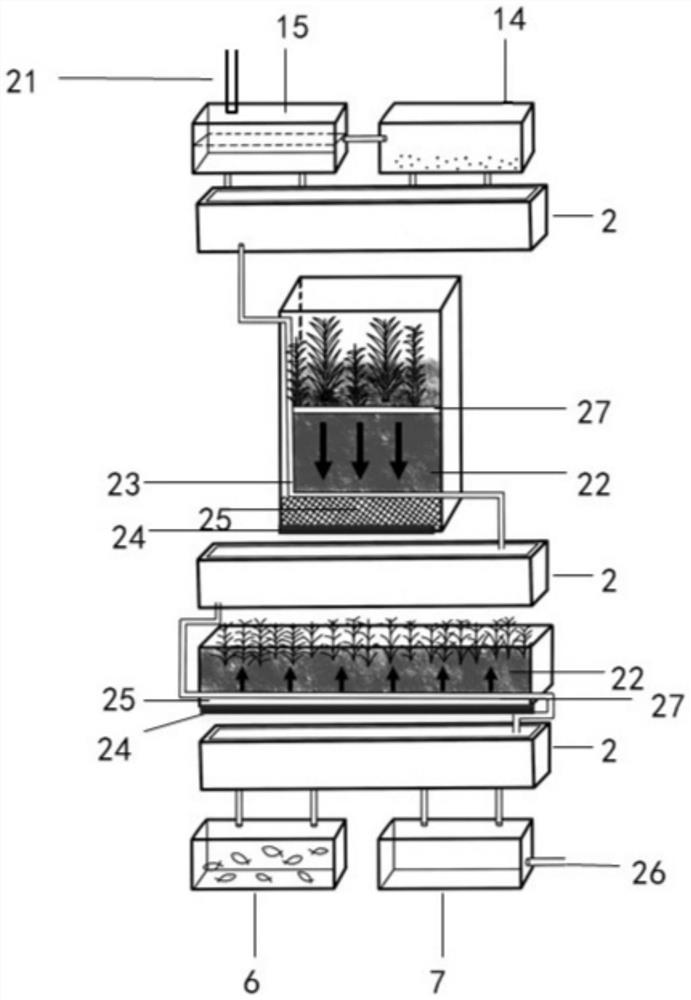

[0059] (1) Introduce the water from the water source into the composite vertical subsurface flow wetland for preliminary purification, and remove and precipitate non-ionic ammonia, nitrite, total coliforms, algae, copper, lead, and sediment in the water body, making the water body The transparency reaches about 15cm, the pH value is maintained at 7.8, and the oxygen content reaches 4mg / L;

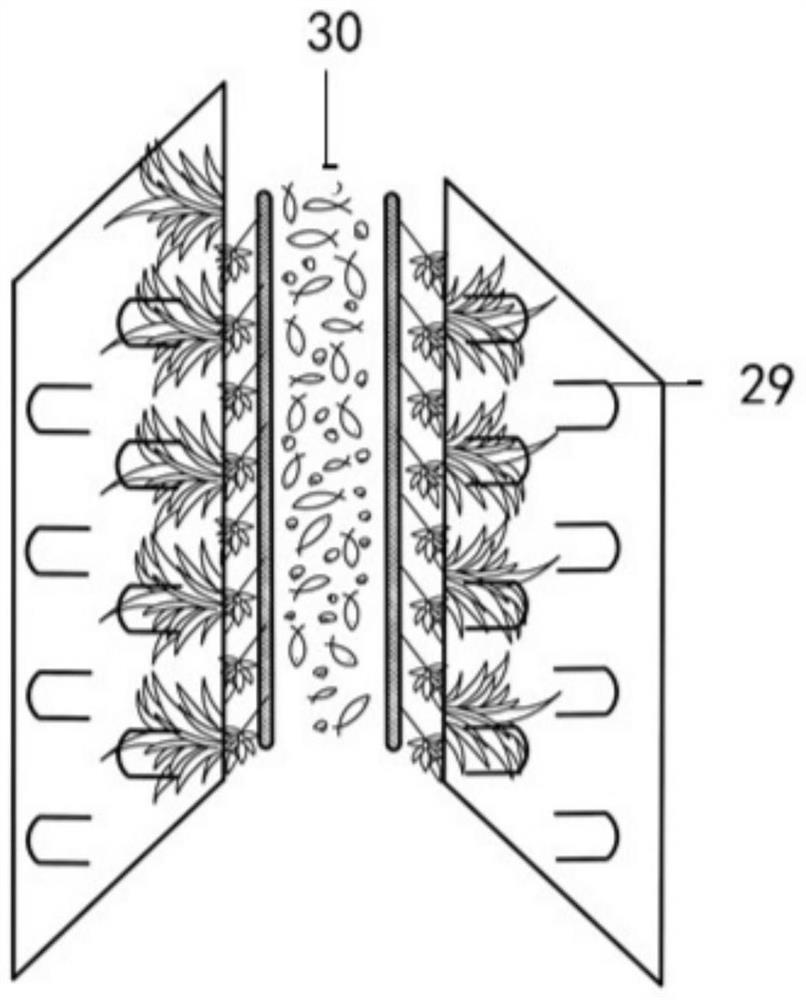

[0060] (2) The settled water is sequentially introduced into the river course of the secondary purification system, the water purification pond of the third purification system and the water storage pond of the fourth purification water storage system;

[0061] (3) Monitor the water quality of the water source in the four-stage purification water storage system, and present the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparency | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com