Lead-free high-voltage medium-temperature sintered strontium bismuth titanium-based dielectric material and preparation method thereof

A dielectric material, strontium-bismuth-titanium technology, is applied in the field of lead-free high-pressure medium-temperature sintered strontium-bismuth-titanium-based dielectric materials and the preparation field, which can solve problems such as limited application range, achieve increased synthesis rate, increased contact area, and energy consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The present invention also provides a method for preparing the lead-free high-pressure medium-temperature sintered strontium-bismuth-titanium-based dielectric material, including:

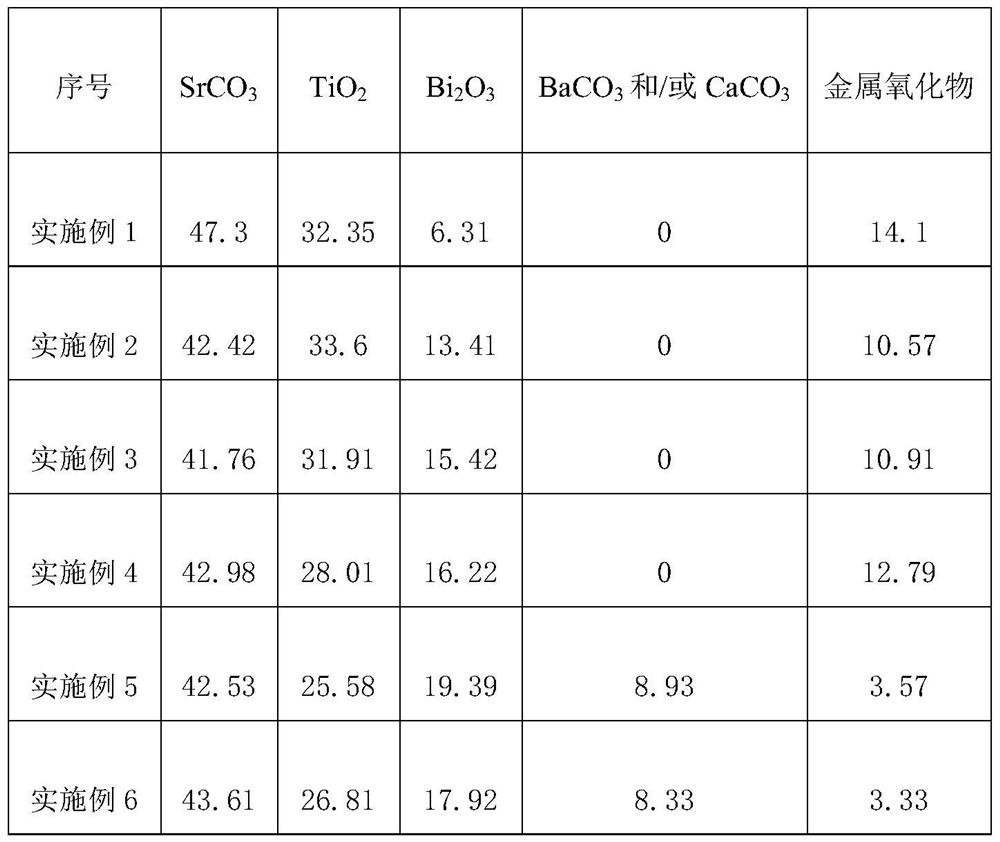

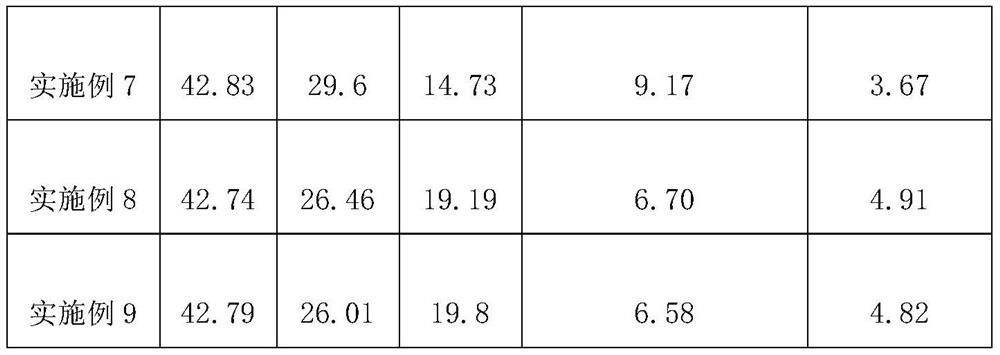

[0022] (1) SrCO 3 、TiO 2 、Bi 2 o 3 、BaCO 3 and / or CaCO 3 and metal oxides in parts by weight to obtain a mixture, with zirconia balls as the grinding medium and water as the solvent; according to the material: ball: water weight ratio of 1:5-6:1.5-2.5 for grinding and mixing 5 -8h to obtain the first mixed slurry; dry the first mixed slurry at 140°C and pass through a 40-mesh sieve, pre-calcine at 1060-1140°C for 3-5h, obtain a synthetic agglomerate and then pulverize to obtain a powder; In this example, SrCO 3 The purity is greater than 97%, TiO 2 The purity is greater than 98%, Bi 2 o 3 for electronic grade.

[0023] (2) The powder is batched again, with zirconia balls as the grinding medium and water as the solvent; according to the material: ball: water weight ratio is 1:5-6:1....

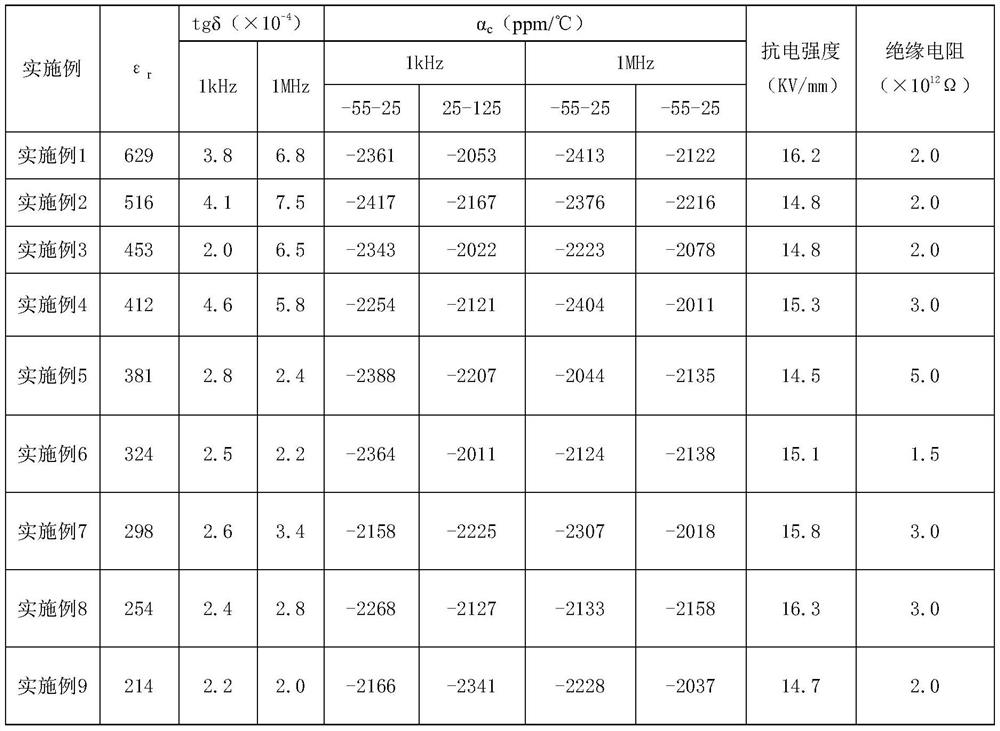

Embodiment 1

[0026] This embodiment provides a method for preparing a lead-free high-pressure medium-temperature sintered strontium-bismuth-titanium-based dielectric material, including: (1) SrCO 3 、TiO 2 、Bi 2 o 3Mix with MgO according to the mass ratio of 47.3:32.35:6.31:14.1 to obtain a mixture, use zirconia balls as the grinding medium, and use water as the solvent; grind and mix according to the material: ball: water weight ratio of 1:5:1.5 8h to obtain the first mixed slurry; dry the first mixed slurry at 140°C and pass through a 40-mesh sieve, pre-fire at 1060°C for 5h, obtain a synthetic burnt block and then pulverize it to obtain a powder; (2) the powder The material is batched again, with zirconia balls as the grinding medium, and water as the solvent; according to the material: ball: water weight ratio of 1:5:1.5, grind and mix for 45 hours, and pass through a 320 mesh sieve to obtain the second mixed slurry; Dry the second mixed slurry at 140°C and pass through an 80-mesh si...

Embodiment 2

[0028] This embodiment provides a method for preparing a lead-free high-pressure medium-temperature sintered strontium-bismuth-titanium-based dielectric material, including: (1) SrCO 3 、TiO 2 、 Bi 2 o 3 and ZrO 2 According to the mass ratio of 42.42:33.6:13.41:10.57, the mixture is obtained by batching, using zirconia balls as the grinding medium, and water as the solvent; according to the material: ball: water weight ratio of 1:5:1.5, grind and mix for 8 hours, Obtain the first mixed slurry; dry the first mixed slurry at 140°C and pass through a 40-mesh sieve, pre-fire at 1060°C for 5 hours, obtain a synthetic agglomerate and then pulverize it to obtain a powder; (2) The powder is again Carry out batching, use zirconia balls as the grinding medium, use water as the solvent; grind and mix for 45 hours according to the weight ratio of material:ball:water of 1:5:1.5, and pass through a 320 mesh sieve to obtain the second mixed slurry; The second mixed slurry is dried at 140°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com