Trimethylsilyl-containing propynyl phosphate compound and preparation method and application thereof

A technology of trimethylsilylpropynyl phosphate and silylpropynyl phosphate, applied in silicon organic compounds, phosphorus organic compounds, chemical instruments and methods, etc., can solve the problems of high cost and affecting the conductivity of electrolyte , to achieve the effects of reducing corrosion, improving storage and cycle performance, and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

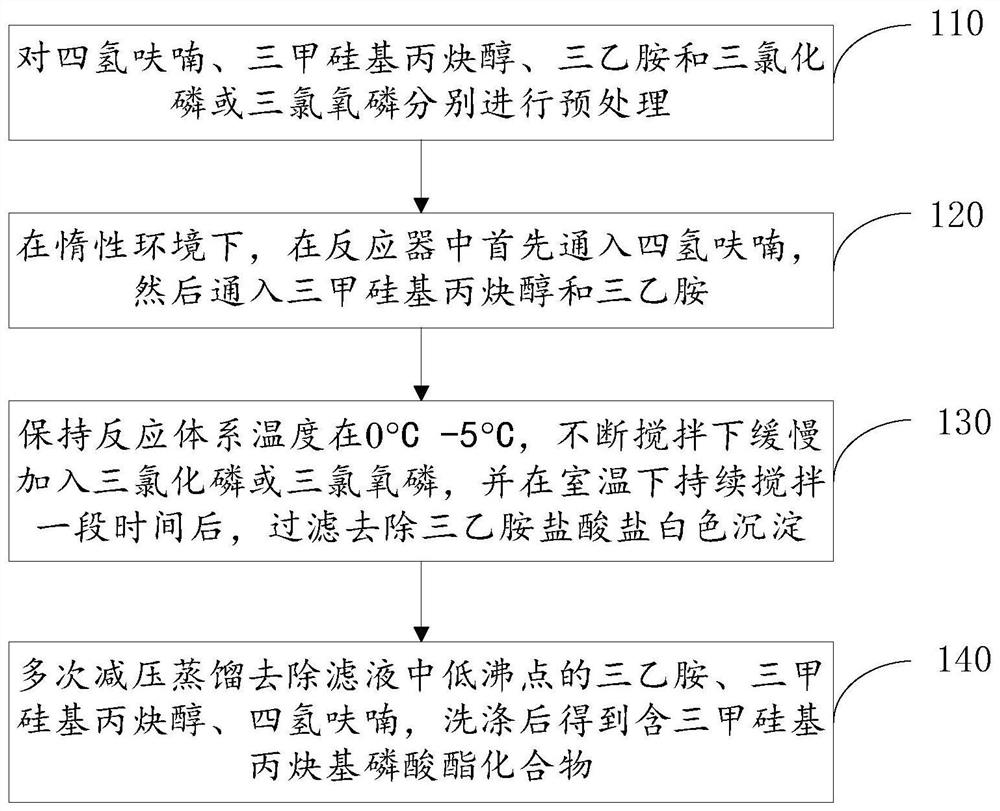

[0043] The trimethylsilyl propynyl phosphate compound of the present invention can be obtained by such as figure 1The shown preparation method process obtains, and main steps comprise:

[0044] In step 110, tetrahydrofuran, trimethylsilylpropynol, triethylamine, and phosphorus trichloride or phosphorus oxychloride are pretreated respectively.

[0045] Specifically, the tetrahydrofuran is heated and distilled, while using metal sodium to dry and remove water, so that the purity of tetrahydrofuran is greater than 99.9%, and the water content is reduced to below 50ppm;

[0046] Heating and fractionating triethylamine to obtain a colorless and transparent triethylamine solution, and then adding activated 4A molecular sieves to make the moisture content of triethylamine lower than 50ppm;

[0047] Add trimethylsilylpropynol, phosphorus trichloride or phosphorus oxychloride to the activated 4A molecular sieve respectively, so that the moisture content of trimethylsilylpropynol, phos...

Embodiment 1

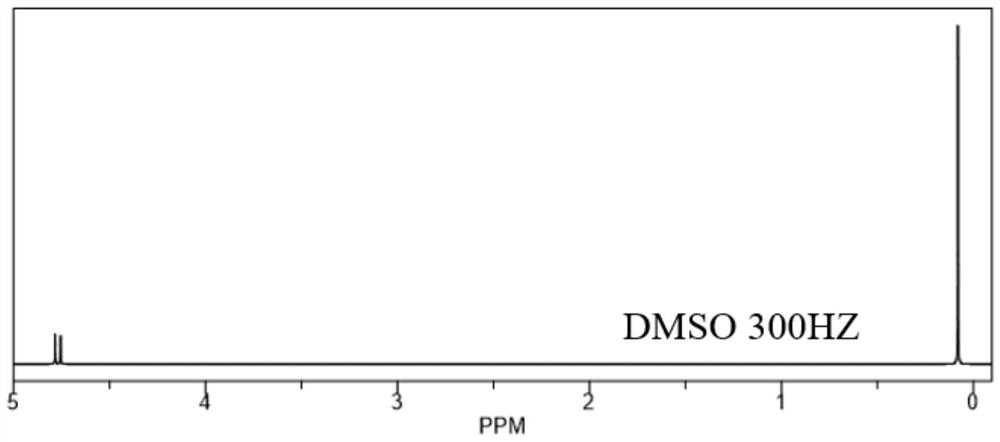

[0060] This embodiment provides a trimethylsilyl propynyl phosphate compound

[0061] Its preparation concrete reaction principle is as follows:

[0062]

[0063] Concrete preparation steps are as follows:

[0064] (1) Raw material pretreatment: heating and distilling tetrahydrofuran, and drying and removing water by using sodium metal at the same time, so that the purity of tetrahydrofuran is greater than 99.9%, and the water content is reduced to below 50ppm; triethylamine is heated and fractionated to obtain a colorless and transparent triethylamine solution, and then Add activated 4A molecular sieve to make triethylamine (Et3N) moisture lower than 50ppm; The moisture content is less than 50ppm.

[0065] (2) The preparation reaction of the silicon-containing benzene sulfonate compound in this embodiment is carried out in an inert atmosphere, and 50 mL of tetrahydrofuran is added after the reactor is filled with an inert gas;

[0066] (3) 0.3mol of trimethylsilyl pro...

Embodiment 2

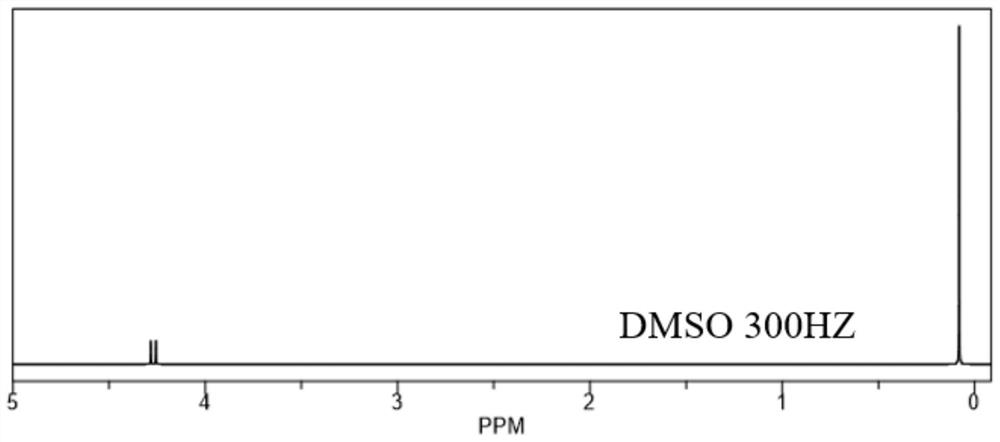

[0072] This embodiment provides a trimethylsilyl propynyl phosphate compound

[0073] Its preparation concrete reaction principle is as follows:

[0074]

[0075] Concrete preparation steps are as follows:

[0076] (7) Raw material pretreatment: heating and distilling tetrahydrofuran, drying and removing water with sodium metal at the same time, so that the purity of tetrahydrofuran is greater than 99.9%, and the water content is reduced to below 50ppm; triethylamine is heated and fractionated to obtain a colorless and transparent triethylamine solution, and then Add activated 4A molecular sieve to make triethylamine (Et3N) moisture lower than 50ppm; The moisture content is less than 50ppm.

[0077] (8) The preparation reaction of the silicon-containing benzene sulfonate compound in this embodiment is carried out in an inert atmosphere, and 50 mL of tetrahydrofuran is added after the reactor is filled with an inert gas;

[0078] (9) 0.3mol of trimethylsilyl propynyl al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com