Self-healing modified asphalt as well as preparation method and application thereof

A self-healing technology of modified asphalt, which is applied to roofs using flexible materials, cohesive pavements paved on site, and roof insulation materials, etc. problems, to achieve the effect of saving time, high degree of regeneration, and low processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

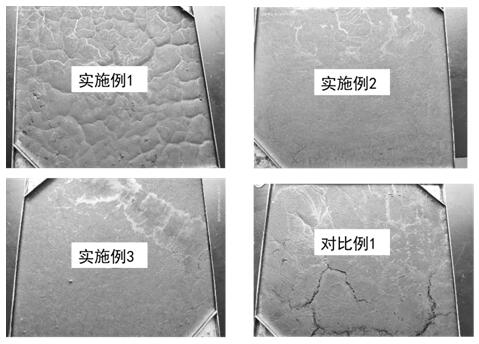

Examples

preparation example Construction

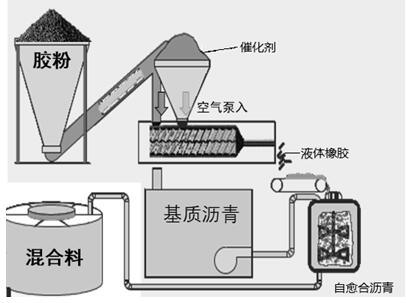

[0049] The preparation method of the above-mentioned self-healing modified asphalt comprises the following steps:

[0050] (1) Add tire rubber powder and a certain amount of metal ion catalyst into the reactive screw extruder, pump air into the reactive screw extruder at the same time, and then extrude to obtain liquid rubber after tire rubber powder degrades , during the extrusion process, the extrusion temperature in the reactive screw extruder is controlled to be 150-200°C;

[0051] (2) Add the liquid rubber obtained in step (1) into the matrix asphalt, the amount of liquid rubber added is at least 30% of the total weight of the final modified asphalt, and then the liquid rubber and the matrix asphalt are stirred and mixed at a temperature of 120-160°C Uniform, self-healing modified asphalt is obtained.

[0052] The device for pumping air into the reactive screw extruder in step (1) is an air pumping device.

[0053] The reactive screw extruder is equipped with an air pum...

Embodiment 1

[0059] 20-mesh rubber powder and 0.05% cobalt naphthenate were stirred and mixed at a high speed, and processed by a reactive extrusion screw at 180° C. to obtain a low Mooney liquid rubber with a sol content of 50%. Mix and add Zhenhai No. 70 bitumen with 20% glue content, and stir the bitumen at 140°C for 20 minutes to prepare self-healing modified bitumen.

Embodiment 2

[0061] 20-mesh rubber powder and 0.05% cobalt naphthenate were stirred and mixed at a high speed, and processed by a reactive extrusion screw at 180° C. to obtain a low Mooney liquid rubber with a sol content of 50%. Mix and add Zhenhai No. 70 bitumen with 30% glue content, and stir the bitumen at 140°C for 20 minutes to prepare self-healing modified bitumen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com