Microneedle patch with ultrathin flexible backing layer and preparation method thereof

A technology of backing layer and microneedle sticking, which is applied in the direction of microneedle, needle, sheet conveying, etc., can solve the problems of increasing the precision, difficulty and cost of microneedle preparation, complicated preparation method, and many material restrictions, and achieves the goal of drying. The effect of short time required, material cost advantages, and huge commercial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Microneedle preparation

[0035] 1. Preparation of microneedle matrix solution

[0036] Take the required amount of hyaluronic acid (10KDa) and dissolve it in ultrapure water to prepare a microneedle matrix solution with a concentration of 100% (100g / 100mL). The viscosity of the matrix solution is 44696cp.

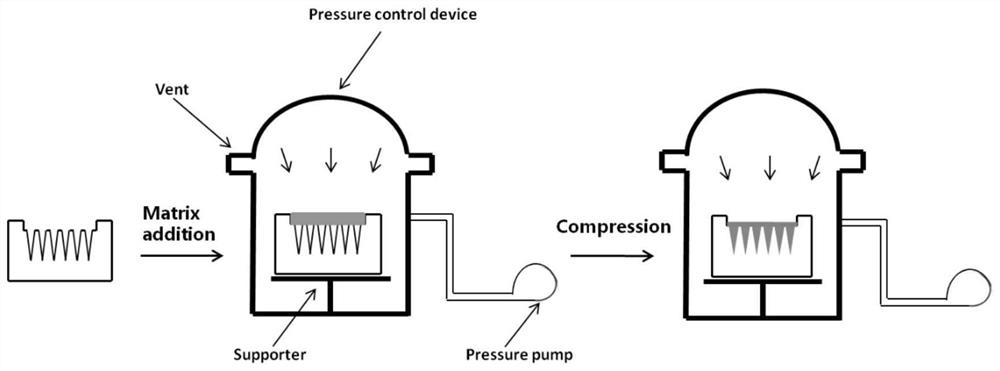

[0037] 2. Pressurized perfusion

[0038] Take 12 μL of the above solution at a time and apply it on the microneedle mold, place the mold as a whole in a pressurized chamber, adjust the pressure to 0.6 MPa, and pressurize for 15 minutes.

[0039] 3. Curing and demoulding

[0040] The pressurized microneedle mold is placed in a desiccator, dried at room temperature for 1.5 hours, and peeled off to obtain the final product.

[0041] 2. Determination of the thickness of the patch backing layer

[0042] The patch thickness was measured to be 20 μm.

[0043] 3. Determination of patch dry weight

[0044] In order to more accurately determine the amount of hyaluron...

Embodiment 2

[0048] 1. Microneedle preparation

[0049] 1. Preparation of microneedle matrix solution

[0050] Dissolve the required amount of hyaluronic acid (10KDa) and rhodamine B in ultrapure water to prepare a microneedle matrix containing rhodamine B 0.2% (100g / 100mL) and sodium hyaluronate 100% (100g / 100mL) liquid, matrix liquid viscosity: 44696cp.

[0051] 2. Pressurized perfusion

[0052] Take 15 μL of the above solution at a time and apply it on the microneedle mold, place the mold as a whole in a pressurized chamber, adjust the pressure to 0.7 MPa, and pressurize for 20 minutes.

[0053] 3. Curing and demoulding

[0054] The pressurized microneedle mold is placed in a desiccator, dried at room temperature for 1.5 hours, and peeled off to obtain the final product.

[0055] 2. Determination of the thickness of the patch backing layer

[0056] The patch thickness was measured to be 25 μm.

[0057] 3. Determination of patch dry weight

[0058] In order to more accurately dete...

Embodiment 3

[0062] 1. Microneedle preparation

[0063] 1. Preparation of microneedle matrix solution

[0064] Take the required amount of hyaluronic acid (10KDa) and dissolve it in ultrapure water to prepare a microneedle matrix solution with a concentration of 100% (100g / 100mL). The viscosity of the matrix solution is 44696cp.

[0065] 2. Pressurized perfusion

[0066] Take 18 μL of the above solution at a time and apply it on the microneedle mold, place the mold as a whole in a pressurized chamber, adjust the pressure to 0.5 MPa, and pressurize for 15 minutes.

[0067] 3. Curing and demoulding

[0068] The pressurized microneedle mold is placed in a desiccator, dried at room temperature for 2 hours, and then peeled off.

[0069] 2. Determination of the thickness of the patch backing layer

[0070] The patch thickness was measured to be 30 μm.

[0071] 3. Determination of patch dry weight

[0072] In order to more accurately determine the amount of hyaluronic acid actually required...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com