Sn-Zn-In-Ga lead-free solder and preparation method thereof

A lead-free solder and solder technology, used in welding equipment, welding/cutting media/materials, welding media, etc., can solve problems such as the adverse effect of solder wettability, limit the application of Sn-Zn solder, and achieve excellent wettability. , low cost, reducing the effect of influencing factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

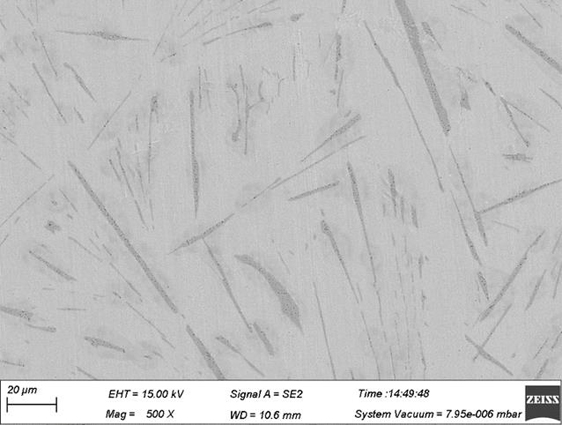

Embodiment 1

[0026] A Sn-Zn-In-Ga lead-free solder, the lead-free solder is composed of the following components by weight percentage: 7.0% Zn, 0.5% In, 1.0% Ga, the balance is Sn, and unavoidable impurities are also included.

[0027] The preparation method of Sn-Zn-In-Ga lead-free solder alloy is as follows:

[0028] (1) Weigh the raw materials Sn and Zn according to the weight ratio of 1:1 and place them in the crucible of the vacuum induction melting furnace. After vacuuming, fill it with argon for melting. The melting temperature is 550°C~650°C, and the melting time is 30min~40min , a vacuum of 10 -4 Pa, the master alloy Sn-Zn is prepared, the alloy is smelted repeatedly for 3 times, poured into a metal mold after the last remelting, and cooled and solidified in an argon atmosphere;

[0029] (2) Weigh the raw materials Sn and In according to the weight ratio of 1:1 and place them in the crucible of the vacuum induction melting furnace. After vacuuming, fill it with argon for melting....

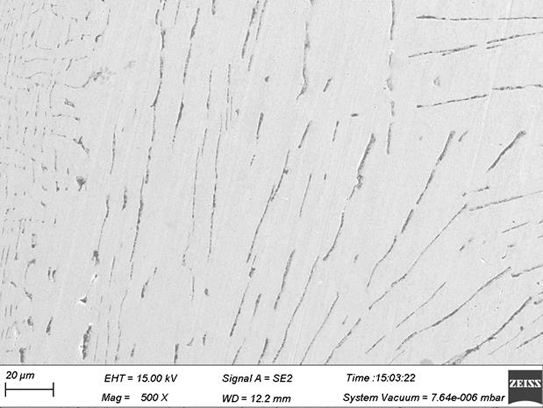

Embodiment 2

[0033] A Sn-Zn-In-Ga lead-free solder, the lead-free solder is composed of the following components by weight percentage: 7.0% Zn, 1.0% In, 0.5% Ga, the balance is Sn, and unavoidable impurities are also included.

[0034] The preparation method of the lead-free solder alloy of this embodiment is the same as the method of embodiment 1, the only difference is that the weight percentage of the Sn-Zn-In-Ga lead-free solder alloy is added according to the ratio in this embodiment, and will not be repeated here.

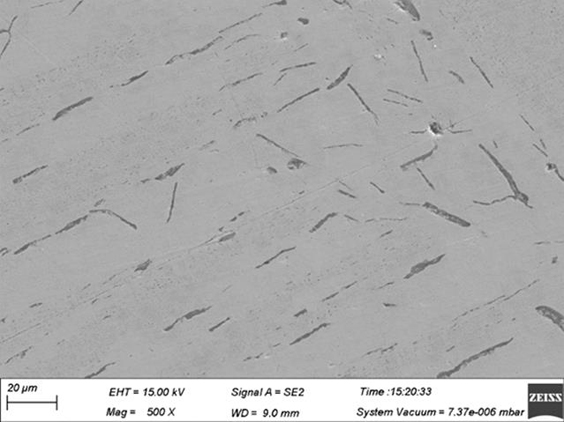

Embodiment 3

[0036] A Sn-Zn-In-Ga lead-free solder, the lead-free solder is composed of the following components by weight percentage: 7.0% Zn, 0.5% In, 2.0% Ga, the balance is Sn, and unavoidable impurities are also included.

[0037]The preparation method of the lead-free solder alloy in this embodiment is the same as the method in embodiment 1, the only difference is that the weight percentage of the Sn-Zn-In-Ga lead-free solder alloy is added according to the ratio in this embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com