Method for synthesizing mesoporous titanium dioxide by adding template agent through ultrasonic coupling and microwave

A technology of mesoporous titanium dioxide and templating agent, applied in titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve problems such as affecting the application of photocatalytic purification technology, easy to agglomerate particles, difficult to obtain particle size and other problems , to achieve the effect of reducing particle agglomeration, small particle size and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

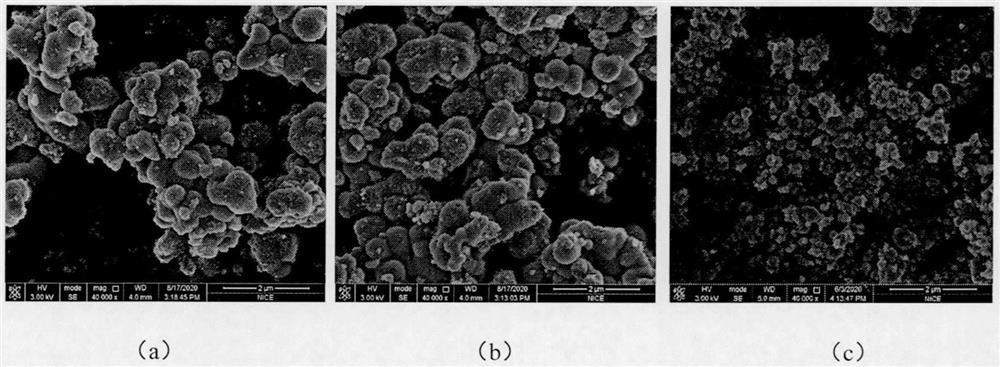

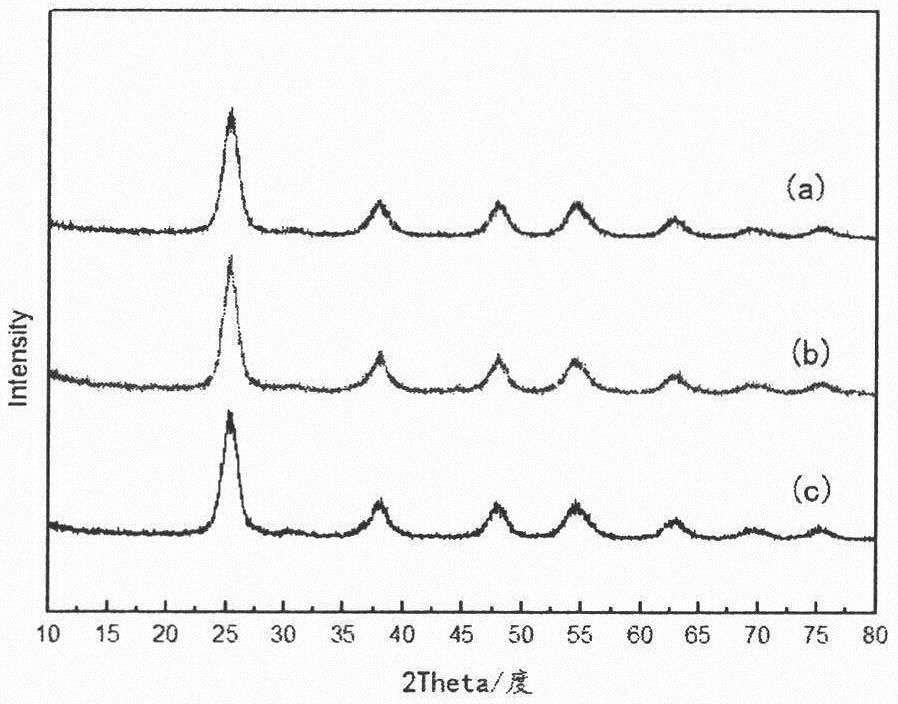

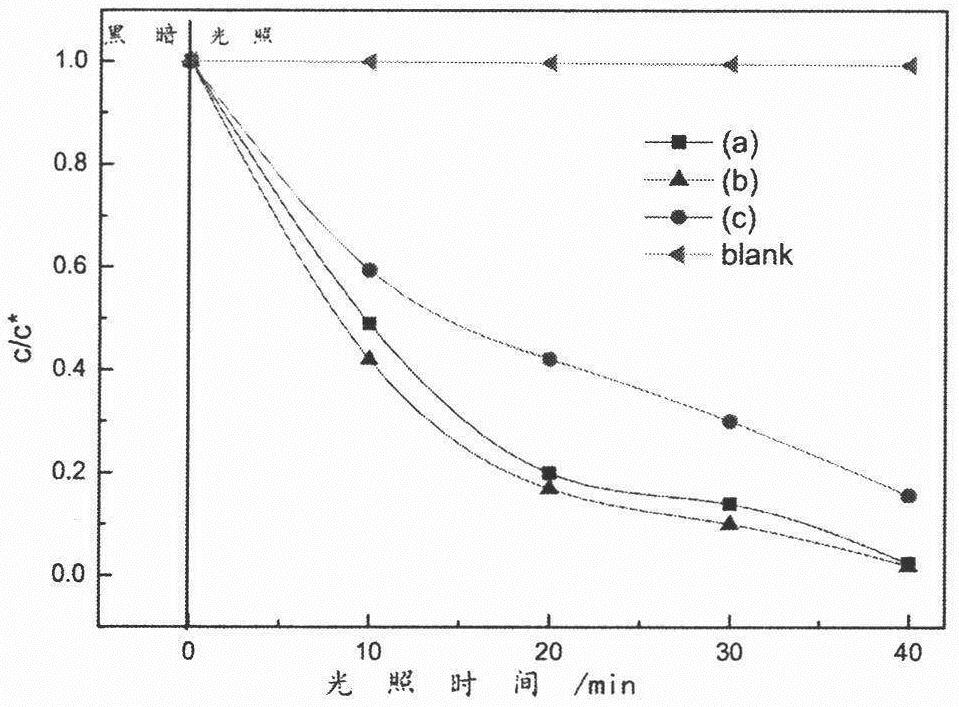

Embodiment 1

[0024] First configure a sodium hydroxide solution with a volume of 80mL and a concentration of 0.09g / L, then configure a mixture of 15.4ml of tetrabutyl titanate, 0.1g of template agent CTAB and 35mL of absolute ethanol. 600rpm, reaction temperature 60℃, ultrasonic power density 0.231W / cm 2 , the ultrasonic operation mode is intermittent operation and the ultrasonic operation cycle is ultrasonic 10s stop 20s, the mixed solution is dripped into the 0.09g / L sodium hydroxide solution at a rate of 100rpm with a peristaltic pump, and at the same time, start timing with a stopwatch, After the dropwise addition is completed, turn off the ultrasonic generator, record the time spent in ultrasonication for 15 minutes, and use deionized water to make up the volume of the obtained precursor to 200mL, stir evenly, and finally transfer the volume-fixed precursor to the microwave reaction device , under the conditions of microwave power density of 1.5W / mL, microwave temperature of 120°C and...

Embodiment 2

[0027]First configure a sodium hydroxide solution with a volume of 80mL and a concentration of 0.09g / L, and then configure a mixed solution of 15.4ml tetrabutyl titanate, 0.2g template agent CTAB and 35mL absolute ethanol. 600rpm, reaction temperature 60℃, ultrasonic power density 0.231W / cm 2 , the ultrasonic operation mode is intermittent operation and the ultrasonic operation cycle is ultrasonic 10s stop 20s, the mixed solution is dripped into the 0.09g / L sodium hydroxide solution at a rate of 100rpm with a peristaltic pump, and at the same time, start timing with a stopwatch, After the dropwise addition is completed, turn off the ultrasonic generator, record the time spent in ultrasonication for 15 minutes, and use deionized water to make up the volume of the obtained precursor to 200mL, stir evenly, and finally transfer the volume-fixed precursor to the microwave reaction device , under the conditions of microwave power density of 1.5W / mL, microwave temperature of 120°C an...

Embodiment 3

[0030] First prepare a sodium hydroxide solution with a volume of 80mL and a concentration of 0.09g / L, and then prepare a mixture of 15.4ml of tetrabutyl titanate and 35mL of absolute ethanol. The magnetic stirrer rotates at 600rpm and the reaction temperature is 60°C. , the ultrasonic power density is 0.231W / cm 2 , the ultrasonic operation mode is intermittent operation and the ultrasonic operation cycle is ultrasonic 10s stop 20s, the mixed solution is dripped into the 0.09g / L sodium hydroxide solution at a rate of 100rpm with a peristaltic pump, and at the same time, start timing with a stopwatch, After the dropwise addition is completed, turn off the ultrasonic generator, record the time spent in ultrasonication for 15 minutes, and use deionized water to make up the volume of the obtained precursor to 200mL, stir evenly, and finally transfer the volume-fixed precursor to the microwave reaction device , under the conditions of microwave power density of 1.5W / mL, microwave t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com