Graphene/pyrolytic carbon/silicon carbide electromagnetic shielding composite material and preparation method thereof

A technology of electromagnetic shielding and composite materials, applied in the fields of magnetic field/electric field shielding, electrical components, etc., can solve the problems of poor mechanical structure performance, lack of structure and function, etc., to achieve super strong and super light density, super high mechanical structure performance, The effect of excellent electromagnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

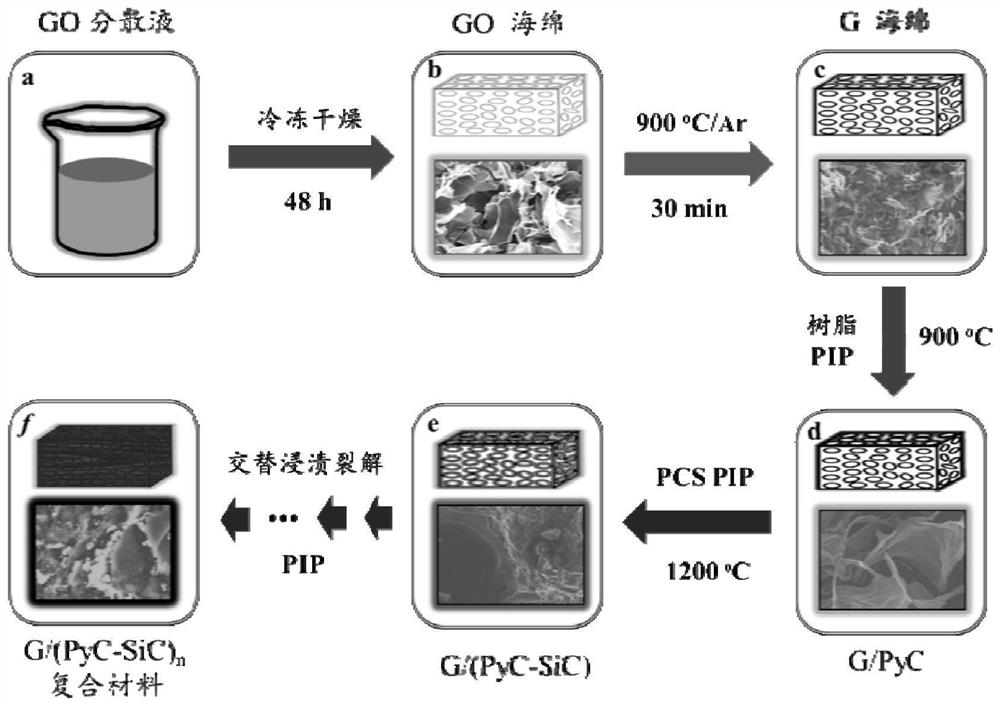

[0036] A kind of preparation method of graphene / pyrolytic carbon / silicon carbide electromagnetic shielding composite material provided by the present invention comprises the following steps:

[0037] Step 1, the preparation of graphene oxide (GO)

[0038] Slowly add 1-5g of graphite powder and 0.5-2g of sodium nitrate into 30-150mL of concentrated sulfuric acid to obtain a mixture, place the mixture in an ice-water bath at 0°C and mix well; then slowly add 3-20g of potassium permanganate, Make it fully stirred in a 35°C water bath to obtain a strong oxidizing concentrated sulfuric acid / potassium permanganate / sodium nitrate-graphite mixture;

[0039] Then slowly add the concentrated sulfuric acid / potassium permanganate / sodium nitrate-graphite mixture into 30-150 mL of deionized water to obtain a dilution with a concentration ratio of the mixture to deionized water of 1;

[0040] Then place the diluted product in a water bath at 90°C to fully react for 30-60 minutes to obtain t...

Embodiment 1

[0058] Step 1, the preparation of graphene oxide (GO);

[0059] Weigh 1g of graphite powder and 0.5g of NaNO respectively 3 , which were sequentially added to 30 mL of concentrated H 2 SO 4 , put the mixture in an ice-water bath at 0°C and stir well, then slowly add 3g KMnO 4 , then placed in a 35°C water bath and stirred for 30min, then added to 30mL of deionized water, and reacted in a 90°C water bath for 15min, after the reaction was completed, slowly added 5 mL of 30% H 2 o 2 solution, let it stand for a period of time, remove the lower layer of sediment, and centrifuge it with ethanol and water until the pH value is 5 to 7, and take the lower layer of sediment to be GO;

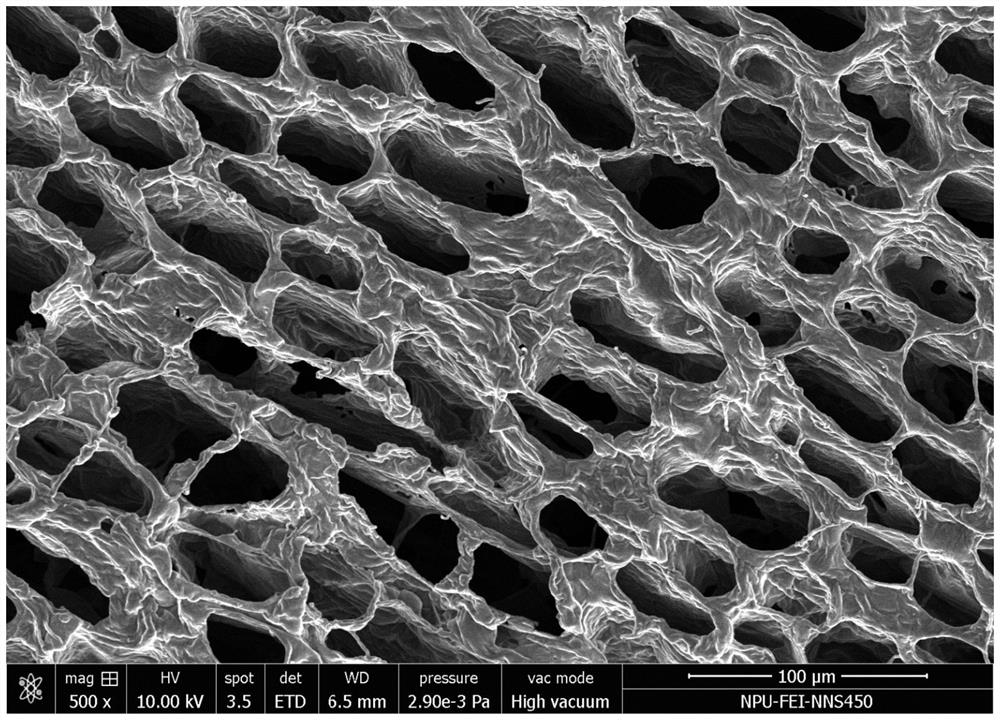

[0060] Step 2, the prepared GO was added with water to form a dispersion with a concentration of 3 mg / mL, ultrasonically treated for 3 hours, then frozen for 24 hours, and then freeze-dried for 48 hours to obtain a three-dimensional skeleton of GO sponge.

[0061] In step 3, the prepared GO sponge t...

Embodiment 2

[0066] Step 1, prepare graphene oxide in the same way as in the first step of Example 1.

[0067] Step 2, the prepared graphene oxide was added with water to form a dispersion with a concentration of 3 mg / mL, ultrasonically treated for 3 hours, then frozen for 24 hours, and then freeze-dried for 48 hours to obtain a three-dimensional skeleton of GO sponge.

[0068] In step 3, the prepared GO sponge three-dimensional skeleton was placed in a tube furnace, and the temperature was raised to 900° C. under nitrogen protection for 30 minutes of high-temperature heat treatment to obtain G sponge.

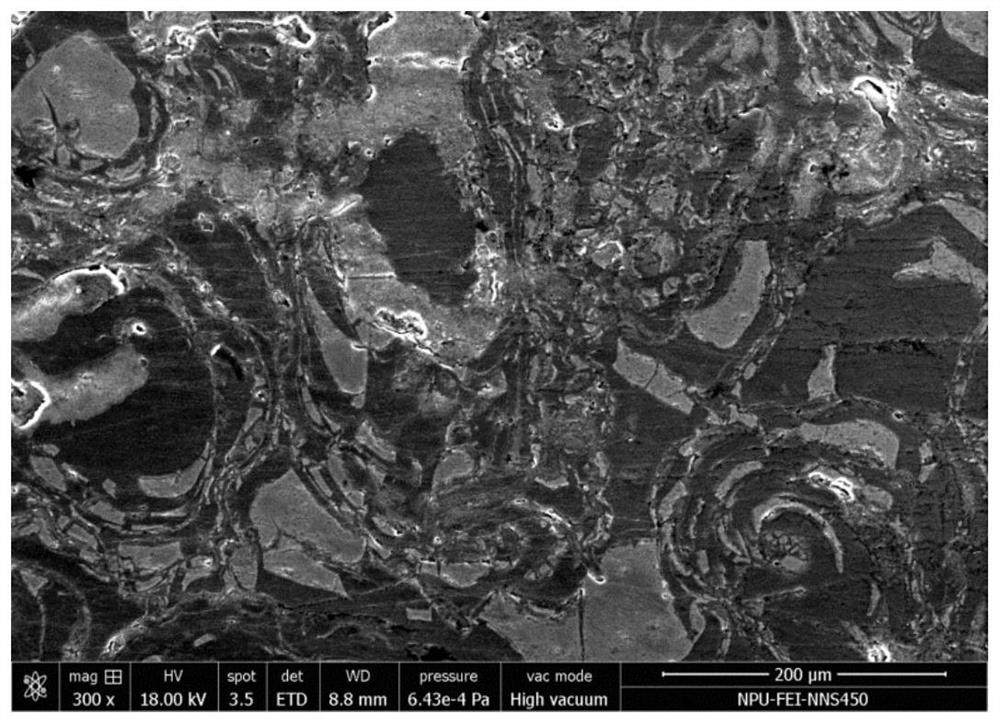

[0069] Step 4, soak the prepared G sponge in an ethanol solution with a mass fraction of 50% resin for 30 minutes, then place it in an oven for curing, and heat it up to 120°C at 1°C / min for 3h. Finally, put it into a tube furnace with nitrogen gas for high temperature cracking, the cracking temperature is 900°C, and the time is 2 hours; take it out and immerse it in the Xylene solution of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com