Water-based acrylic emulsion as well as preparation method and application thereof

A technology of water-based acrylic acid and methacrylic acid, applied in the direction of coating, etc., to achieve the effect of low film forming temperature, high hardness and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

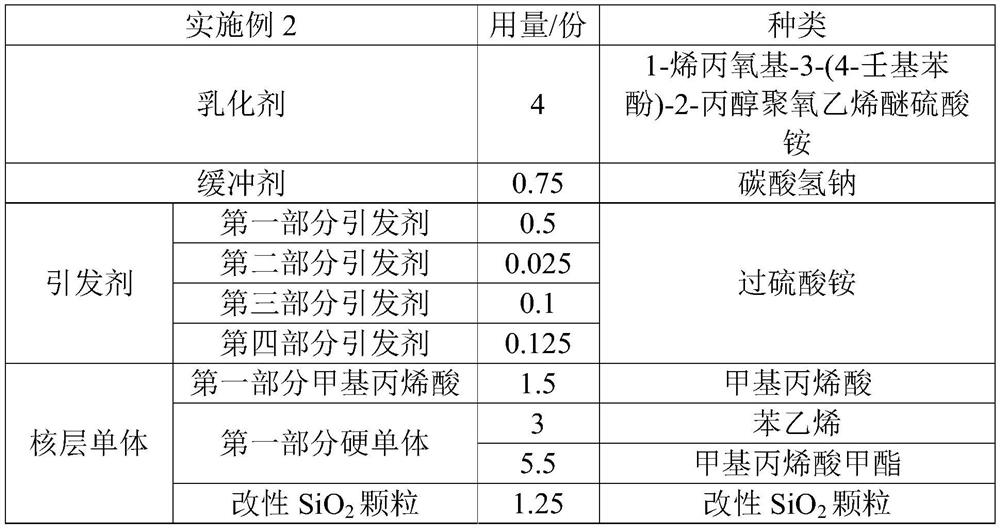

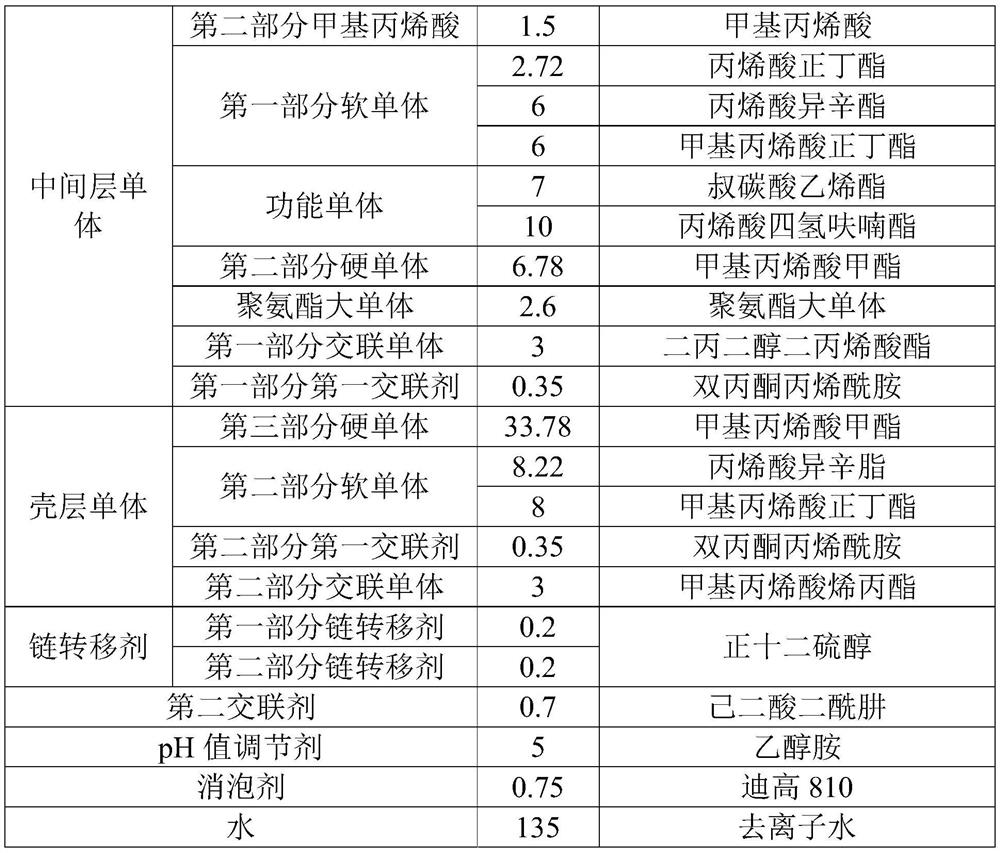

Examples

preparation example Construction

[0040] In the present invention, the polyurethane macromonomer is prepared by the following method: 0.01-0.05wt% dibutyltin dilaurate, 50-70wt% glycol, 20-30wt% dibutyltin dilaurate, 20-30wt% Add the isocyanate into the reaction kettle, react at a reaction temperature of 80-90°C for 2-3 hours, and then add the mixture of 5-12wt% monohydric alcohol and 5-10wt% hydroxyethyl acrylate to the above-mentioned reaction kettle React in medium for 2-3 hours, cool down and discharge to obtain a polyurethane macromonomer, wherein the total amount of the reaction raw materials is the sum of the amounts of dibutyltin dilaurate, glycol, diisocyanate, monohydric alcohol and hydroxyethyl acrylate.

[0041] In the present invention, the water can be water of various hardnesses, commonly used tap water, well water, distilled water, purified water and deionized water can be used, preferably deionized water.

[0042] Preferably, the antifoaming agent is a polyether siloxane copolymer, for example...

Embodiment approach

[0053] According to a preferred embodiment of the present invention, a certain weight ratio of emulsifier, buffer, the first part of the initiator and water are heated and stirred in the reaction kettle, and the temperature is raised to 70-80° C. and stirred for 20 minutes to obtain a mixed solution, wherein , the reactor is equipped with a condenser and high-speed stirring.

[0054] According to the present invention, in step (2), the first part of methacrylic acid, the first part of hard monomer, modified SiO 2 The timing of introducing the particles and the second part of the initiator into the mixed solution is not particularly limited. Preferably, after the mixed solution in step (1) is heated to 70-80°C, the first part of methacrylic acid, the first part of hard monomer, the modified SiO 2 Particles and a second portion of initiator are introduced into the mixed liquor. In this preferred situation, it is beneficial to improve the particle size uniformity of the core la...

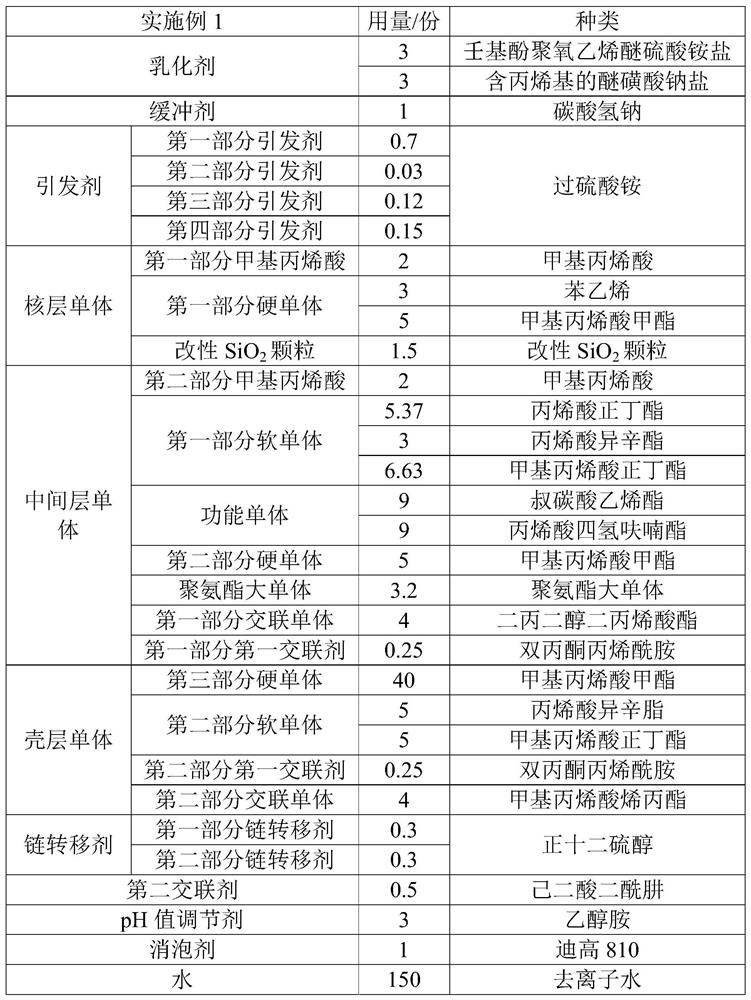

Embodiment 1

[0087] (1) The emulsifier, the buffer, the first part of the initiator and the deionized water are mixed in the reaction kettle for the first time, and the temperature is raised to 75° C. to obtain the mixed solution;

[0088] (2) the first part of methacrylic acid, the first part of hard monomer, modified SiO 2 Particles and the second part of the initiator are introduced into the mixed solution for 0.5 hours, and then incubated for 0.5 hours to obtain the first solution;

[0089] (3) The second part of methacrylic acid, the first part of soft monomer, functional monomer, the first part of crosslinking monomer, the second part of hard monomer, the first part of the first crosslinking agent, the first part of chain transfer agent, polyurethane The macromonomer and the third part of the initiator are introduced into the first solution for 2 hours, and then incubated for 0.5 hours to obtain the second solution;

[0090] (4) The third part of hard monomer, the second part of sof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com