Polyaspartic acid ester prepolymer and preparation method thereof, and corresponding coating

A technology of aspartic acid ester and prepolymer, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problem of low elongation at break, achieve insensitivity to temperature and humidity, and improve elongation at break rate, the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

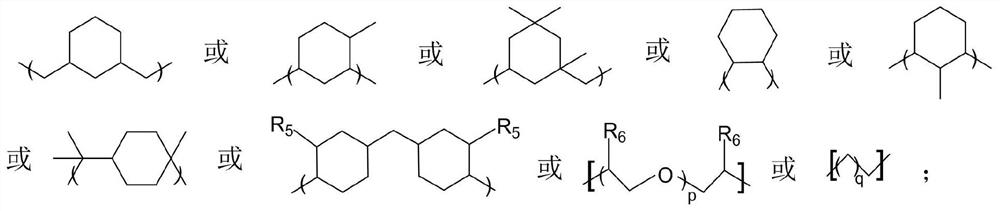

[0024] A polyaspartic acid ester prepolymer, which is a reaction product formed by the reaction of dibasic alcohol, dibasic isocyanate and small molecular type aspartic acid ester; the dibasic alcohol, the dibasic isocyanate and the described The molar ratio between small molecule aspartic acid esters is 1:1.5-3:1-8. The molar weight of the small molecule aspartic acid ester is 2-4 times of the difference between the dibasic isocyanate molar weight and the dibasic alcohol molar weight. The dihydric alcohol is composed of one or more components with the structure HO-R-H, wherein R is R 0 It is H or Me, and the value range of n is 2-30; n 1 The value range is 1-50. The dibasic isocyanate has a structure of OCN-R 1 -One or more components of NCO, wherein, R 1 for R 2 For H or Me. The small molecular polyaspartic acid ester has a structure of Composed of one or more components, wherein, R 3 for R 4 It is a straight chain or branched chain alkyl group containing 1...

Embodiment 2

[0026] A polyaspartic acid ester prepolymer, which is a reaction product formed by the reaction of dibasic alcohol, dibasic isocyanate and small molecular type aspartic acid ester; the dibasic alcohol, the dibasic isocyanate and the described The molar ratio between small molecule aspartic acid esters is 1:2-2.5:2-6. The molar weight of the small molecule aspartic acid ester is 2-4 times of the difference between the dibasic isocyanate molar weight and the dibasic alcohol molar weight. The dihydric alcohol is composed of one or more components with the structure HO-R-H, wherein R is R 0 It is H or Me, and the value range of n is 2-30; n 1 The value range is 1-50. The dibasic isocyanate has a structure of OCN-R 1 -One or more components of NCO, wherein, R 1 for R 2 For H or Me. The small molecular polyaspartic acid ester has a structure of Composed of one or more components, wherein, R 3 for R 4 It is a straight chain or branched chain alkyl group containing 1...

Embodiment 3

[0028] A preparation method of polyaspartic acid ester prepolymer, comprising the following steps:

[0029] Step 1: Under the protection of an inert gas, the temperature is controlled at 60-80°C, and the diol is slowly and uniformly dropped into the dibasic isocyanate to react, and the temperature is lowered after the reaction to obtain the intermediate.

[0030] Step 2: Under the protection of inert gas, the temperature is controlled at 40-60°C, and the above intermediate is slowly and uniformly dropped into the small molecule aspartic acid ester for reaction, and the polyaspartic acid ester prepolymer is obtained by cooling down after the reaction .

[0031] The steps 1 and 2 judge whether the reaction is completed according to the -NCO value of the detection reaction system; when in the step 1, the -NCO value of the reaction system reaches the theoretical remaining -NCO value, it is determined that the reaction of the step 1 is completed; When in step 2, the -NCO value of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com