PP calcium plastic material for improving printing suitability for packaging box and preparation method of PP calcium plastic material

A calcium-plastic material and technology for suitability are applied to improve the printing suitability of PP calcium-plastic materials for packaging boxes. In the field of preparation of this material, problems such as poor polar ink adsorption, poor printing tinting strength, and increased production links can be solved. , to achieve the effect of improving grip, printing, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

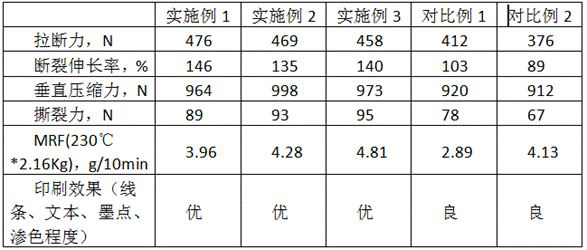

Examples

Embodiment 1

[0031] A PP calcium-plastic material for improving printing suitability for packaging boxes, including the following raw materials in parts by mass: 53.5 parts of a mixture of homopolymerized PP resin and copolymerized PP resin with a mass ratio of 1:1, 1.5 parts of LLDPE, and heavy calcium carbonate 45 parts, 1.5 parts of borate multifunctional additives, 0.5 parts of a mixture of anti-aging agent hindered phenolic antioxidant and phosphite antioxidant with a mass ratio of 1:1.

[0032] The preparation method of the above-mentioned PP calcium-plastic material for improving the printing suitability of the packaging box is as follows: weigh each raw material according to the above-mentioned raw material composition, put it into a high-speed blender, and stir at a temperature of 90°C for 35min at a stirring speed of 1600rpm. The obtained blending components were added to a twin-screw extruder for extrusion and granulation. The temperature of each zone was 200°C, 210°C, 220°C, and...

Embodiment 2

[0034] A PP calcium-plastic material for improving printing suitability for packaging boxes, including the following raw materials in parts by mass: 48 parts of a mixture of homopolymerized PP resin and copolymerized PP resin with a mass ratio of 1.5:1, 2 parts of LLDPE, and heavy calcium carbonate 50 parts, 2 parts of borate multifunctional additives, 0.8 parts of a mixture of anti-aging agent hindered phenolic antioxidant and phosphite antioxidant with a mass ratio of 1:1.

[0035] The preparation method of the above-mentioned PP calcium-plastic material for improving the printing suitability of the packaging box is as follows: weigh each raw material according to the above-mentioned raw material composition, put it in a high-speed blender, and stir for 30 minutes at a temperature of 100 ° C. The stirring speed is 1550 rpm. The obtained blended components were added to a twin-screw extruder for extrusion and granulation. The temperature of each zone was 205°C, 215°C, 225°C, a...

Embodiment 3

[0037] A PP calcium-plastic material for improving printing suitability for packaging boxes, including the following raw materials in parts by mass: 47 parts of a mixture of homopolymerized PP resin and copolymerized PP resin with a mass ratio of 1.5:1, 3 parts of LLDPE, and heavy calcium carbonate 50 parts, 2.5 parts of borate multifunctional additives, 0.8 parts of a mixture of anti-aging agent hindered phenolic antioxidant and phosphite antioxidant with a mass ratio of 1:1.

[0038] The preparation method of the above-mentioned PP calcium-plastic material for improving the printing suitability of the packaging box is as follows: weigh each raw material according to the above-mentioned raw material composition, put it into a high-speed blender, and stir for 25 minutes at a temperature of 105 ° C. The stirring speed is 1500 rpm. The obtained blended components were added to a twin-screw extruder for extrusion and granulation. The temperature of each zone was 205°C, 215°C, 225°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com