Method for forming molten pool through side-blown smelting furnace in thermal state

A smelting furnace and molten pool making technology, applied in electric furnaces, crucible furnaces, rotary drum furnaces, etc., can solve the problems of large power consumption and electrodes, long material melting time, long molten pool making time, etc., to increase the reaction intensity. , The production and installation are simple and fast, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

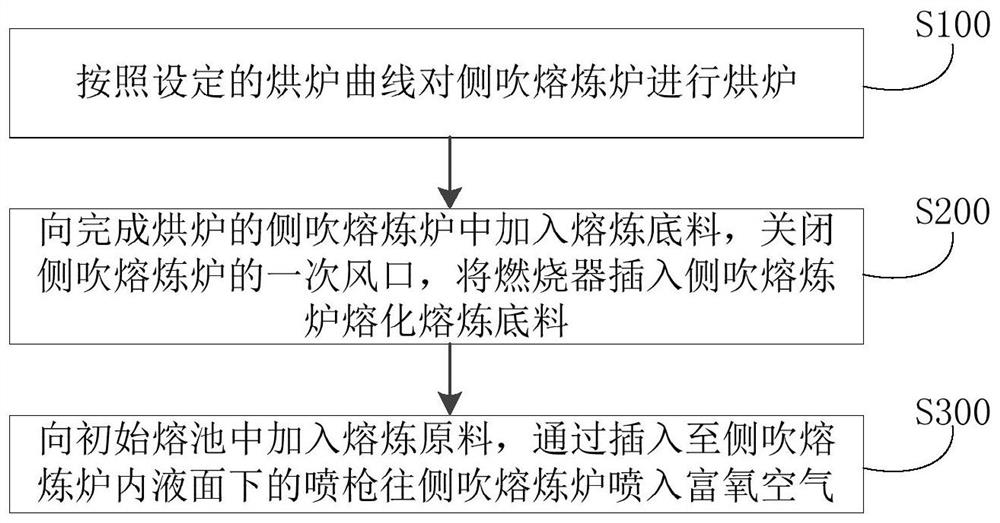

[0040] Baking the side-blowing smelting furnace according to the set baking curve. After the baking is completed, the temperature in the side-blowing smelting furnace is 1200°C;

[0041] Add 100t of copper matte into the side-blowing smelting furnace through the feeding system as the smelting bottom material, bolt the primary tuyeres on both sides of the side-blowing smelting furnace body, insert 3 burners from 3 feeding ports, and use natural gas as the fuel for the burners , the total natural gas flow rate is 800Nm 3 / h, use high temperature to melt and smelt the bottom material to form an initial molten pool, and the liquid level height of the initial molten pool is 500mm;

[0042] Make the spray gun in advance, remove the burner after the initial molten pool is formed, install a spray gun, insert it into the side-blowing smelting furnace from the feeding port, and add smelting raw materials into the side-blowing smelting furnace through the feeding system, including copper...

Embodiment 2

[0044] Baking the side-blowing smelting furnace according to the set baking curve. After the baking is completed, the temperature in the side-blowing smelting furnace is 1200°C;

[0045] Add 110t of copper matte into the side-blowing smelting furnace through the feeding system as the smelting bottom material, bolt the primary tuyeres on both sides of the side-blowing smelting furnace body, insert 3 burners from the 3 feeding ports, and use natural gas as the fuel for the burners , the total natural gas flow rate is 850Nm 3 / h, use high temperature to melt and smelt the bottom material to form an initial molten pool, and the liquid level height of the initial molten pool is 550mm;

[0046] Make the spray gun in advance, remove the burner after the initial molten pool is formed, install 2 spray guns, insert them into the side-blowing smelting furnace from the feeding port, and add smelting raw materials into the side-blowing smelting furnace through the feeding system, including...

Embodiment 3

[0048] Baking the side-blowing smelting furnace according to the set baking curve, after finishing the baking, the temperature inside the side-blowing smelting furnace is 1200°C;

[0049] Add 120t of copper matte into the side-blowing smelting furnace through the feeding system as the smelting bottom material, bolt the primary tuyeres on both sides of the side-blowing smelting furnace body, insert 3 burners from 3 feeding ports, and use heavy oil as the fuel for the burners , the total heavy oil flow rate is 500kg / h, and the base material is melted and smelted at high temperature to form an initial molten pool, and the liquid level height of the initial molten pool is 600mm;

[0050] Make the spray gun in advance, remove the burner after the initial molten pool is formed, install 2 spray guns, insert them into the side-blowing smelting furnace from the feeding port, and add smelting raw materials into the side-blowing smelting furnace through the feeding system, including coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com