A kind of umami peptide and its preparation method and application

A umami peptide and freeze-drying technology, which is applied in the field of preparation of taste peptides, can solve the problems of poor emulsification of products, achieve high taste intensity, and improve the effect of umami intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

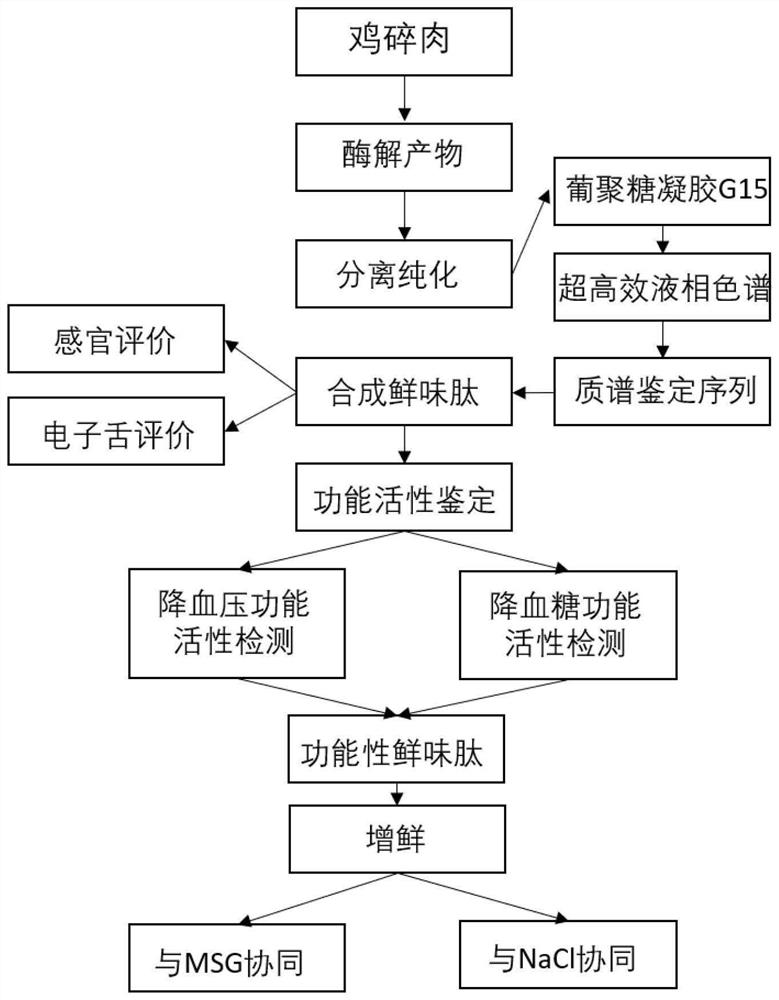

Method used

Image

Examples

Embodiment 1

[0064] (1) Use minced chicken meat as raw material, pass it through a meat grinder, and then add water, the ratio of material to liquid is 1.5:1 (m:v), that is, the ratio of minced chicken meat to water is 1.5g: 1mL.

[0065] (2) Add 0.1% flavor protease of chicken minced meat mass, enzymolyze at 54°C and pH value 6.0-8.0 for 1.5h, add 0.25% of chicken mass for enzymolysis with compound protease for 2.5h, inactivate enzyme at 90°C for 15min, Obtain chicken enzymatic hydrolyzate.

[0066] (3) Filtration: the enzymatic hydrolyzate is filtered by step-by-step sieving, so that the filtrate is separated from the filter residue, and the filtrate is taken and freeze-dried to obtain a freeze-dried enzymatic hydrolyzate.

[0067] (4) Separating and purifying the freeze-dried enzymatic hydrolyzate with dextran gel, selecting the component with the strongest umami taste through electronic tongue and sensory evaluation, and freeze-drying to obtain a freeze-dried gel component.

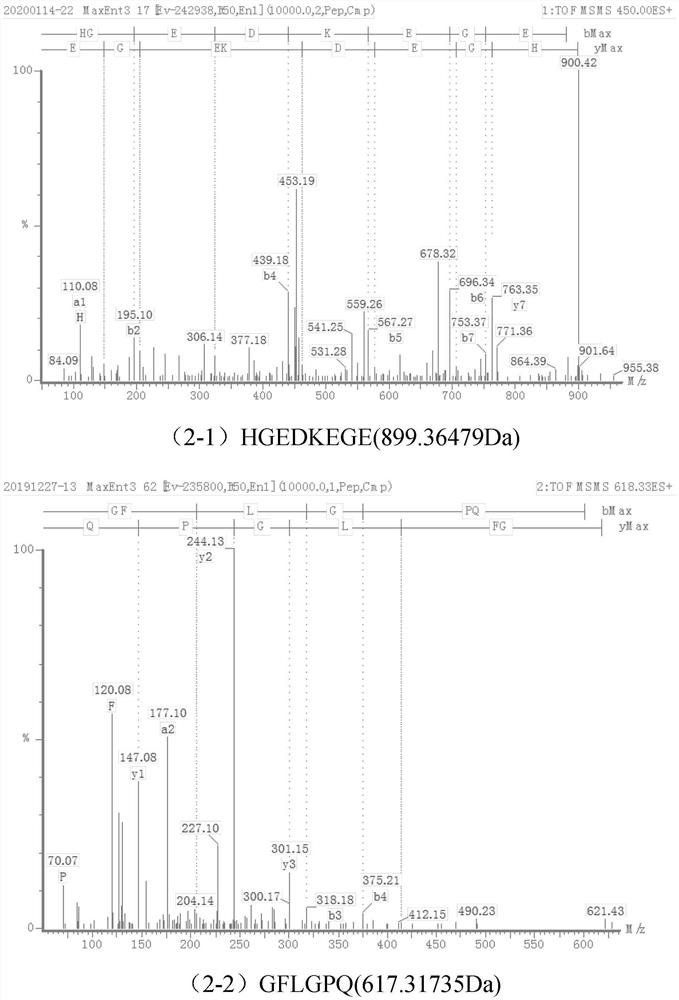

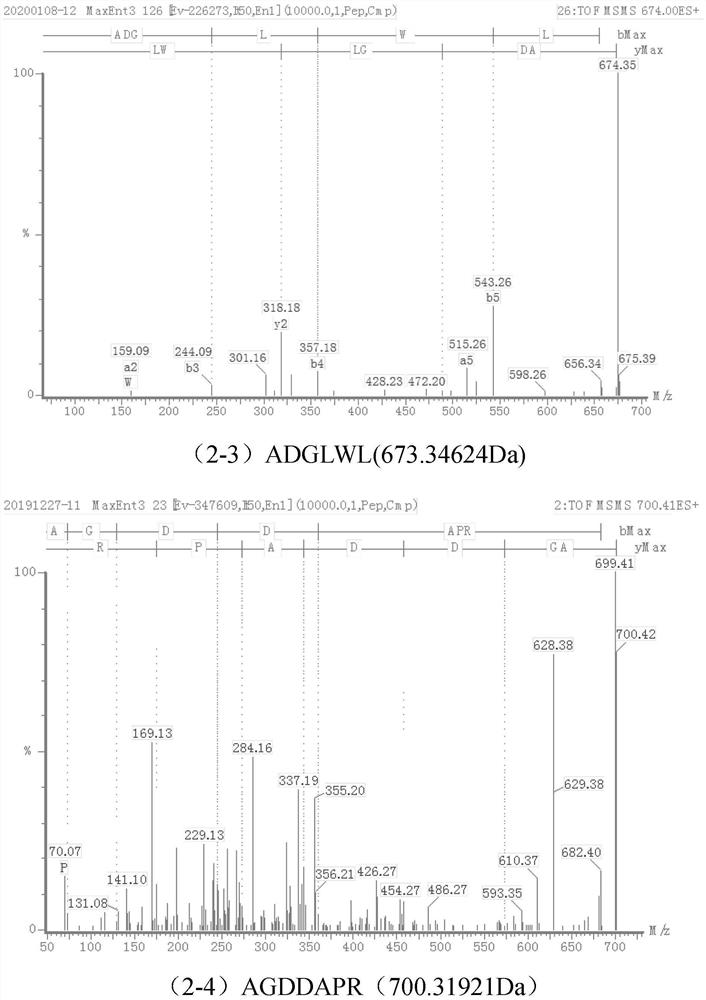

[0068] T...

Embodiment 2

[0081] (1) Use minced chicken meat as raw material, pass it through a meat grinder, and then add water, the ratio of material to liquid is 1.5:1 (m:v), that is, the ratio of minced chicken meat to water is 1.5g: 1mL.

[0082] (2) Add 0.1% flavor protease of chicken minced meat mass, enzymolyze at 54°C and pH value 6.0-8.0 for 1.5h, add 0.25% of chicken mass for enzymolysis with compound protease for 2.5h, inactivate enzyme at 90°C for 15min, Obtain chicken enzymatic hydrolyzate.

[0083] (3) Filtration: the enzymatic hydrolyzate is filtered by step-by-step sieving, so that the filtrate is separated from the filter residue, and the filtrate is taken and freeze-dried to obtain a freeze-dried enzymatic hydrolyzate.

[0084] (4) Separating and purifying the freeze-dried enzymatic hydrolyzate with dextran gel, selecting the component with the strongest umami taste through electronic tongue and sensory evaluation, and freeze-drying to obtain a freeze-dried gel component.

[0085] T...

Embodiment 3

[0094] (1) The ten synthetic peptide sequences were screened for blood pressure lowering function.

[0095] (2) Activity detection of peptides with ACE inhibitory activity, comprising the following steps:

[0096] Add 80 μL 5 mmol / L HHL (hippuryl-histidyl-leucine) (dissolved in HEPES buffer, pH 8.3) and 30 μL sample solutions of different concentrations (dissolved in double-distilled water) into a centrifuge tube, mix After placing in a water bath at 37°C for 5 minutes, 40 μL of 0.025 U / mL ACE (dissolved in HEPES buffer, pH 8.3) was added, incubated at 37°C for 1 hour, and then 150 μL of 1M hydrochloric acid was added to terminate the reaction. In the blank group, hydrochloric acid was added at the same time as ACE, in the control group, 30 μL of double distilled water was used instead of the sample solution, and captopril (10 ng / mL) was used as a positive control. After the reaction was completed, the content of hippuric acid (HA) in the sample was detected by RP-HPLC, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com