Thiodiglycol molecularly imprinted polymer as well as preparation method and application thereof

A technology of thiodiglycol and molecular imprinting, which is applied in the field of analysis and detection, can solve problems such as unsatisfactory peak shape and difficult on-site real-time detection of TDG, and achieve beneficial selectivity, good sensitivity, and improved detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of thiodiglycol molecularly imprinted polymer

[0039] Add α-methacrylic acid to the thiodiglycol solution, sonicate for 10 minutes and mix well, then add N,N-dimethylmethylene bisacrylamide, sonicate for 30 minutes and mix well, then add ammonium persulfate, and ultrasonically treat at 35°C The intermediate product is obtained after 1 hour. The intermediate product is soaked in chloroform, after ultrasonic treatment for 10 minutes, placed on a shaker and shaken for 50 minutes. During the shaking, replace the previous hypochloroform with new chloroform for 2 times, and take the solid phase at 30°C Dry to constant weight to prepare thiodiglycol molecularly imprinted polymer, in which the molar mass ratio of α-methacrylic acid, thiodiglycol, N,N-dimethylmethylenebisacrylamide and ammonium persulfate It is 2:1:0.08:0.05, mol:mol:mg:mg.

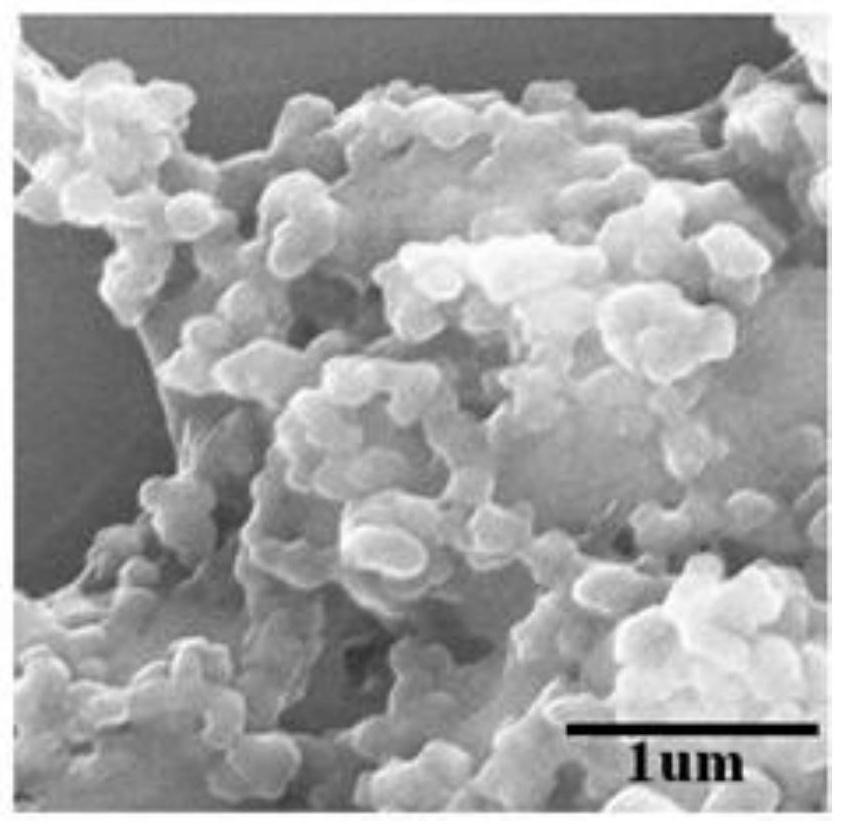

[0040] The SEM image of the intermediate product in Example 1 is as follows figure 1 Shown by figure 1 It can be seen that the in...

Embodiment 2

[0042] Preparation of test paper for detecting mustard gas poisoning marker thiodiglycol

[0043] Add α-methacrylic acid to the thiodiglycol solution, sonicate for 10 minutes and mix well, then add N,N-dimethylmethylene bisacrylamide, sonicate for 30 minutes and mix well, then add ammonium persulfate, and add 5×10mm Soak the nitrocellulose membrane in it. After ultrasonic treatment at 35°C for 1 hour, take out the nitrocellulose membrane and soak in chloroform. After ultrasonic treatment for 10 minutes, place it on a shaker and shake for 50 minutes. During shaking, replace with new chloroform before Hypochloroform was replaced twice, the nitrocellulose membrane was taken out and dried to constant weight at 30°C to prepare a test paper for detecting mustard gas poisoning marker thiodiglycol. Among them, α-methacrylic acid, thiodiglycol, The molar mass ratio of N,N-dimethylmethylenebisacrylamide and ammonium persulfate is 2:1:0.08:0.05, mol:mol:mg:mg.

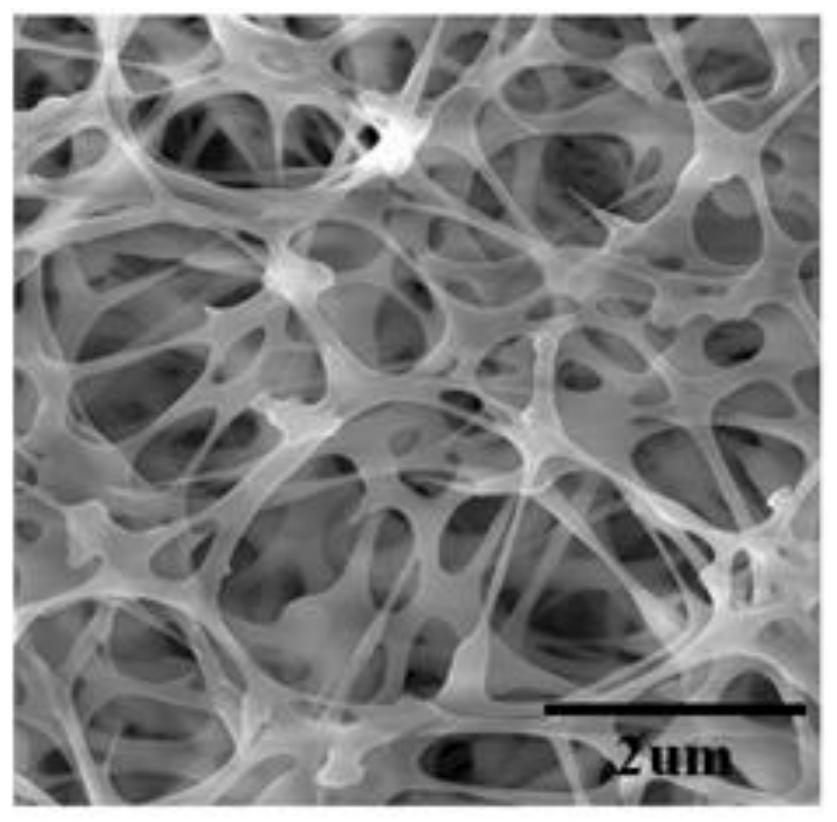

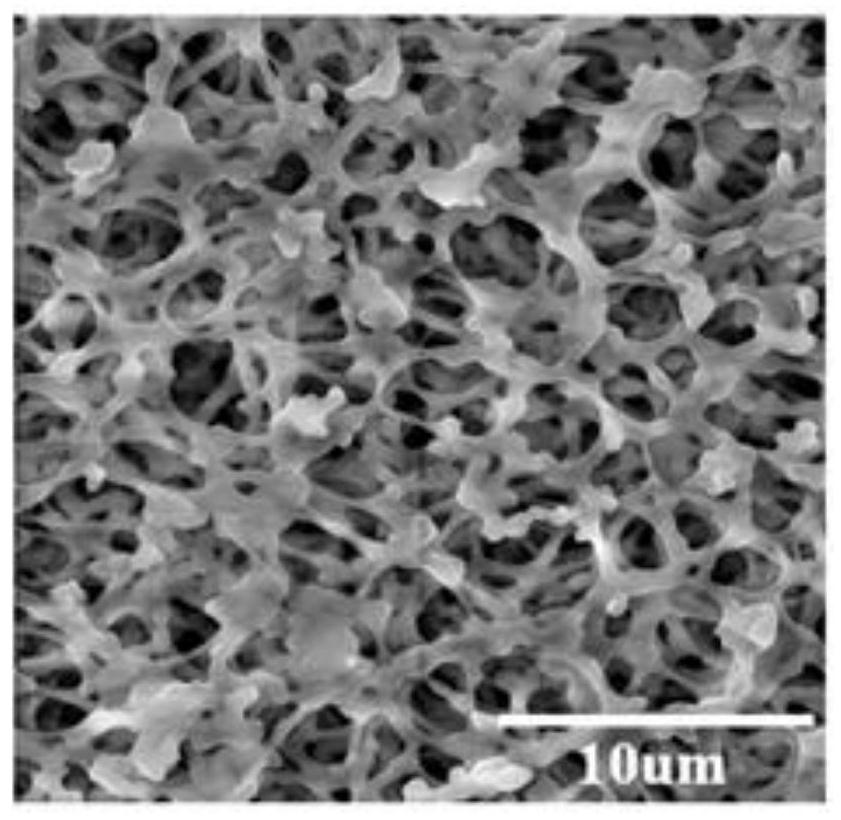

[0044] The SEM image of the n...

Embodiment 3

[0053] On the basis of Example 2, the molar ratio of thiodiglycol and α-methacrylic acid was set to 1:0, 1:2, 1:4, 1:6, and 1:8 to investigate the template molecule and function The effect of the molar ratio of monomers on the color development of the test strip, the results are as follows Image 6 Shown by Image 6 It can be seen that when the molar ratio of thiodiglycol and α-methacrylic acid is 1:2, the red value of the test paper is the strongest. This is because one molecule of thiodiglycol can form hydrogen bonds with two molecules of α-methacrylic acid. Therefore, when the molar ratio of the two is 1:2, the thiodiglycol molecularly imprinted polymer that specifically recognizes thiodiglycol can be prepared, so that the final prepared test paper has the best thiodiglycol sensing performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com