A kind of low-density ultraviolet radiation resistant polyurethane sponge and preparation method thereof

A polyurethane sponge and UV-resistant technology, which is applied in the field of polyurethane sponge production, can solve the problems of affecting the output rate of the sponge, the effect is not necessarily obvious, and the foam height is reduced, and achieves good self-release ability, low equipment requirements, and low total cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4 and comparative example 1-2

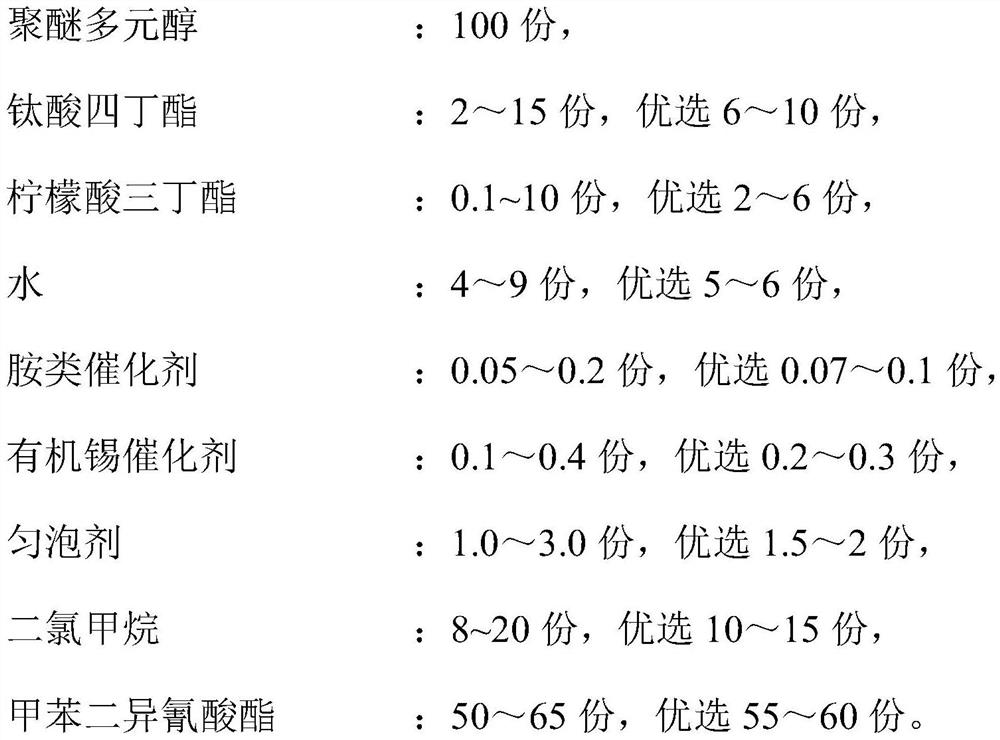

[0035] Anti-ultraviolet radiation type polyurethane sponge, according to parts by weight, its formula is as shown in table 1:

[0036] Table 1 embodiment and comparative example formula are as follows

[0037] Comparative example 1 Comparative example 2 Example 1 Example 2 Example 3 Example 4 Polyether polyol F3156 100 100 100 100 100 100 Tetrabutyl titanate 6 6 10 2.5 14 tributyl citrate 0.5 8 5 1.2 water 5 5 5 8 9 7 Triethylenediamine 0.13 0.1 0.13 0.1 0.05 0.07 stannous octoate 0.1 0.1 0.1 0.4 0.3 0.2 Silicone oil B8123 2 2 2 1.5 2 2.5 Dichloromethane 16 16 16 10 15 9 TDI 52 52 52 60 65 55

[0038] The preparation method of ultraviolet radiation resistant type polyurethane sponge comprises the following steps:

[0039] (1) Premixing: 50 parts of dehydrated polyether polyol F3156 with a water content of 180ppm are premixed with tetrabutyl titanate an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of unsaturation | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com