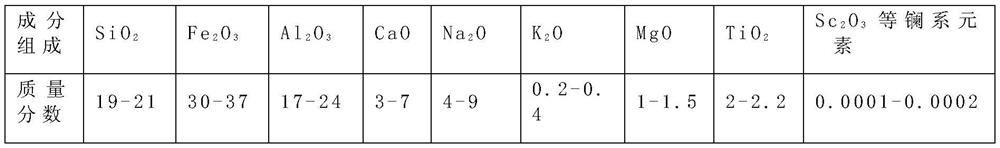

Process method for extracting rare metal oxides from slag ball waste generated in process of producing rock wool by using red mud

A process method and oxide technology, applied in the direction of improving process efficiency, etc., can solve the problems of high energy consumption, large amount of wastewater treatment, low scandium content, etc., and achieve the effect of uniform particle size of the output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

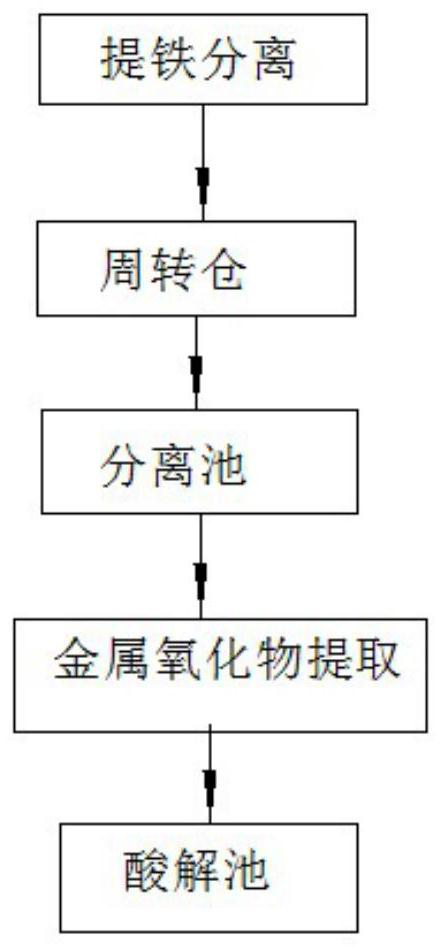

[0093] A method for extracting rare metal oxides from slag ball waste produced in the process of producing rock wool from red mud, the steps are as follows:

[0094] 1. The slag ball waste realizes the complete separation of iron:

[0095] (1) Use a forklift to send the collected slag ball waste into the slag ball waste to be processed silo. The volume of the silo to be processed is generally selected as 50-100m 3 , the silo to be processed adopts a bucket-shaped design, supported by a steel bracket, the top is open, and there is a discharge port under the silo to be processed. A vibrator is arranged near the discharge port below to prevent the slag ball waste from forming an arch in the silo to be processed, and to realize uniform discharge of the slag ball waste from the discharge port of the silo to be processed. The slag waste is sent to the magnetic separator Ⅰ through the automatic belt conveyor Ⅰ to send the slag scraps with high iron content to the magnetic separator...

Embodiment 2

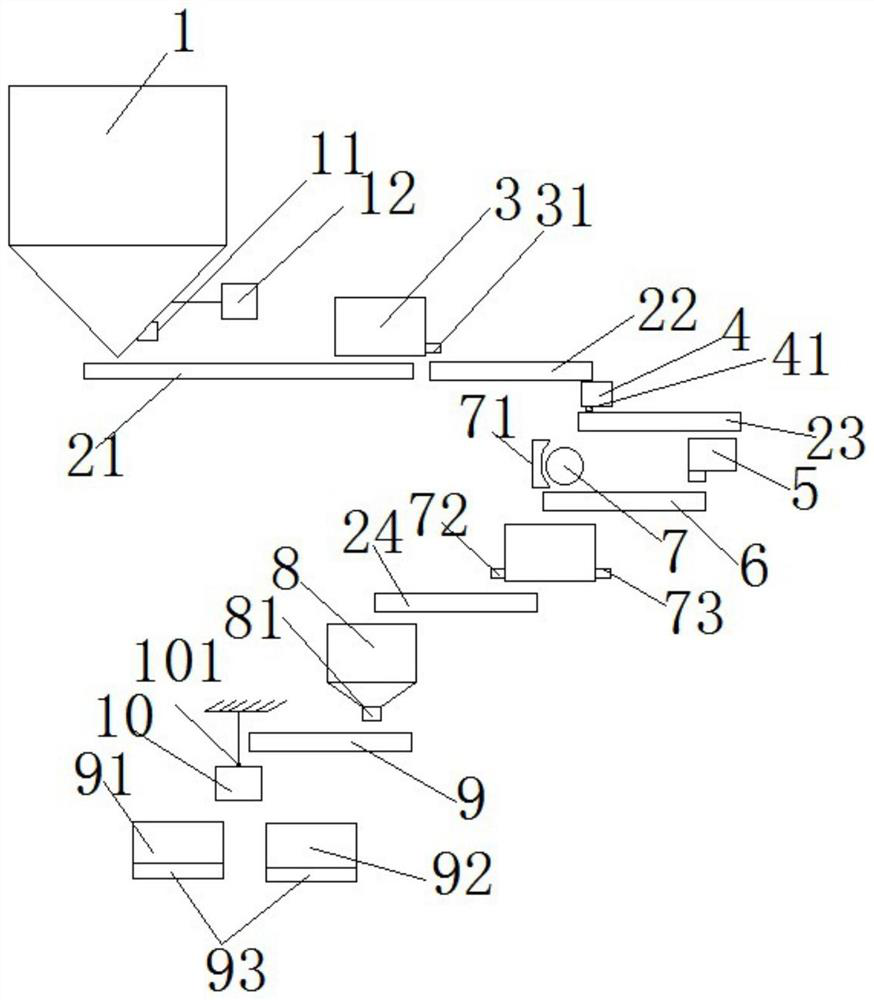

[0115] A device for extracting rare metal oxides from slag ball waste produced in the process of producing rock wool from red mud, specifically as follows: it includes a silo 1 for slag ball waste to be treated, and the volume of the slag ball waste to be treated is generally selected to be 50-100m 3 , the silo to be processed is bucket-shaped, supported by steel brackets, the top is open, and the bottom of the silo to be processed is provided with a discharge port 11, which is docked with the feed end of the automatic belt conveyor Ⅰ21; the discharge port 11 It is arranged under the side of the bin 1 to be treated, and a vibrator 12 is set near the discharge port 11 to prevent the slag ball waste in the bin 1 to be processed from forming an arch, and to realize the uniform discharge of the slag ball waste at the discharge port of the bin to be treated.

[0116] The discharge port 11 of the bin to be processed is docked with the feeding end of the automatic belt conveyor I21, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com