Ti3C2-MXene modified alpha-iron oxide photoelectrode and preparation method thereof

An iron oxide light and electrode technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of complex steps, low charge transfer efficiency, poor conductivity, etc. The effect of poor conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

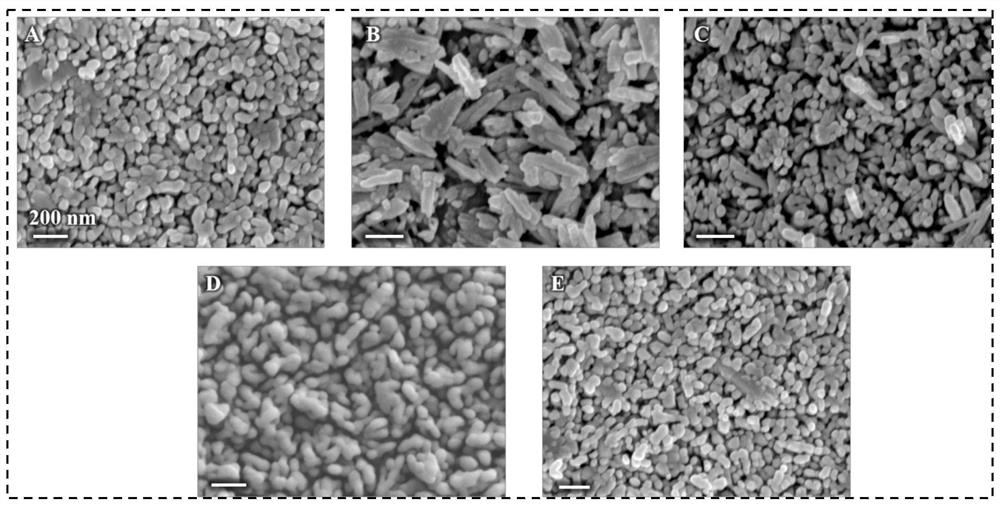

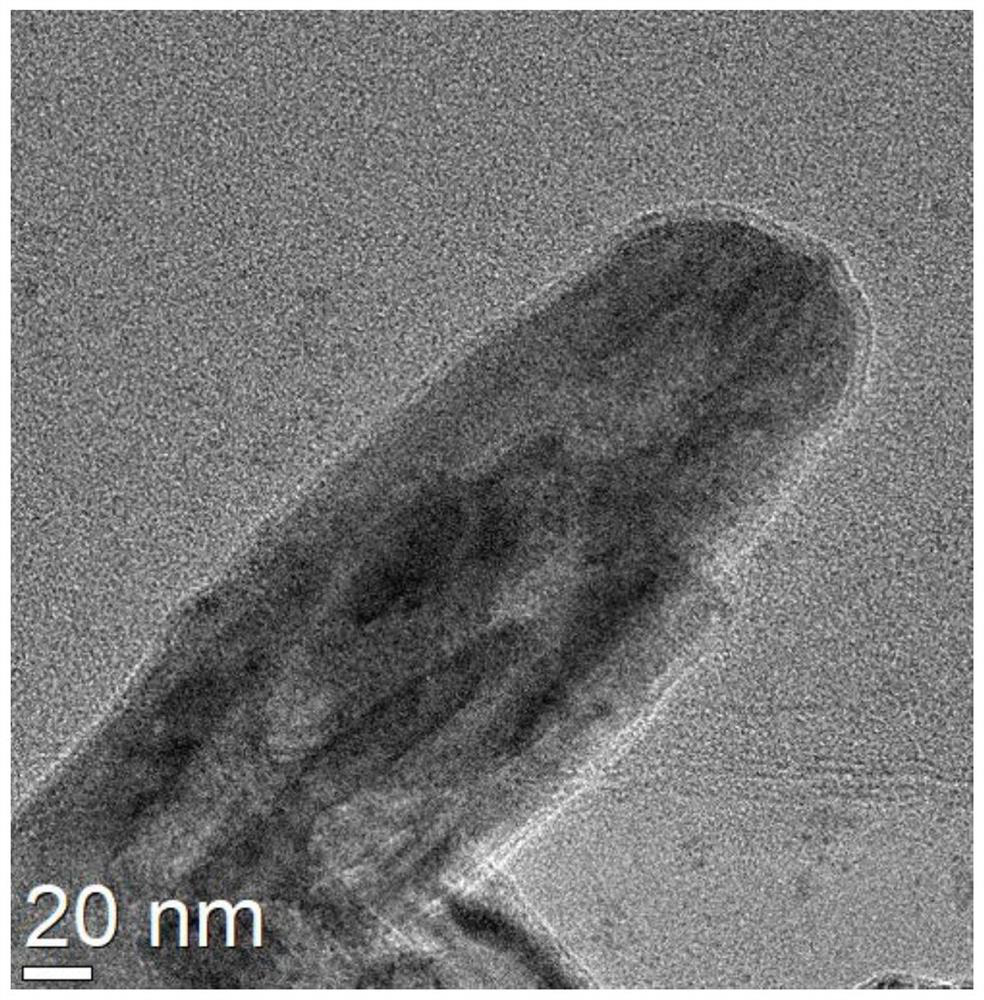

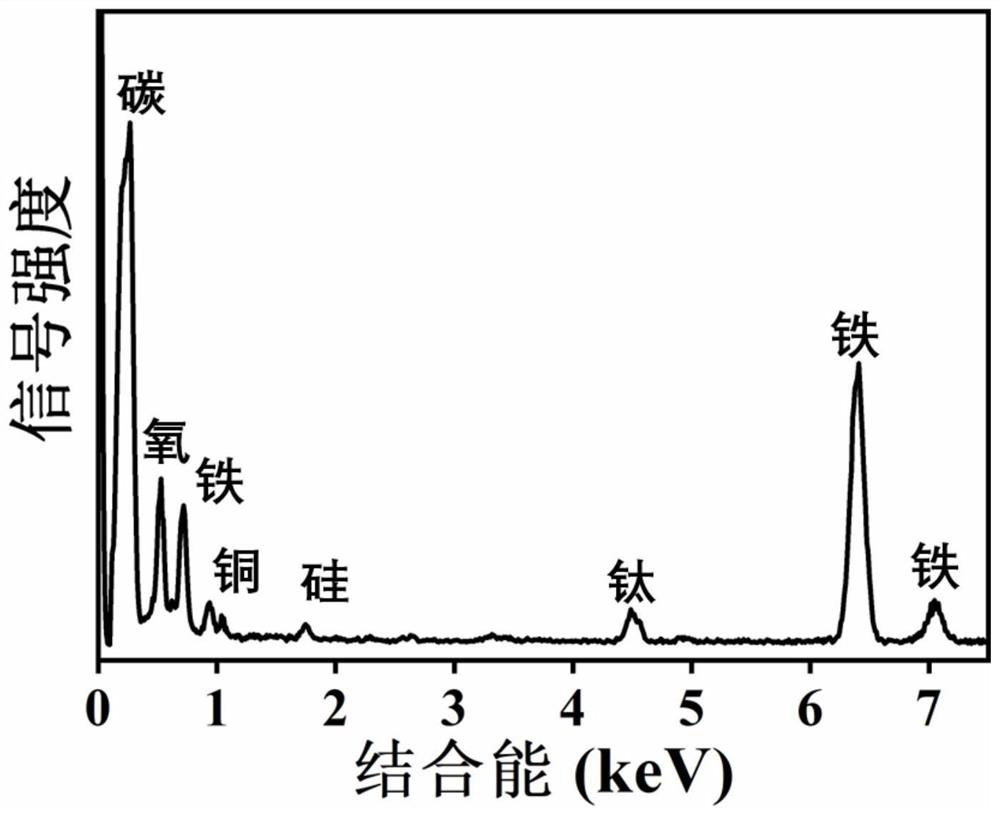

[0039] Ti 3 C 2 -MXene-modified α-iron oxide photoelectrode, wherein the feed amount in the hydrothermal method is: Ti 3 C 2 - 50 mg of MXene, 250 mg of ferric chloride, 1 mol / L of sodium nitrate aqueous solution, and a total volume of 10 mL of the reaction solution.

[0040] The above Ti 3 C 2 -The preparation method of the α-iron oxide photoelectrode of MXene modification, comprises following preparation steps:

[0041] (1) Put Ti 3 C 2 The powder was dissolved in water (100mg / 100mL), ultrasonicated for 3 hours, and freeze-dried to obtain two-dimensional Ti 3 C 2 - MXene nanosheets;

[0042] (2) Put the FTO conductive glass in the reactor, and add ferric chloride, Ti 3 C 2 -MXene nanosheets and sodium nitrate aqueous solution;

[0043] (3) React the reactor at 150°C for 5 hours. After the reaction, take out the iron oxide and Ti deposited on the surface. 3 C 2 - MXene's FTO conductive glass, cleaned in the order of ultrapure water / absolute ethanol / ultrapure wat...

Embodiment 2

[0047] Ti 3 C 2 -MXene-modified α-iron oxide photoelectrode, wherein the feed amount in the hydrothermal method is: Ti 3 C 2 - 20 mg of MXene, 250 mg of ferric chloride, 1 mol / L of sodium nitrate aqueous solution, and a total volume of 10 mL of the reaction solution.

[0048] The above Ti 3 C 2 -The preparation method of the α-iron oxide photoelectrode of MXene modification, comprises following preparation steps:

[0049] (1) Put Ti 3 C 2 The powder was dissolved in water (50mg / 100mL), ultrasonicated for 2 hours, and freeze-dried to obtain two-dimensional Ti 3 C 2 - MXene nanosheets;

[0050] (2) Put the FTO conductive glass in the reactor, and add ferric chloride, Ti 3 C 2 -MXene nanosheets and sodium nitrate aqueous solution;

[0051] (3) React the reactor at 150°C for 5 hours. After the reaction, take out the iron oxide and Ti deposited on the surface. 3 C 2 - MXene's FTO conductive glass, cleaned in the order of ultrapure water / absolute ethanol / ultrapure wate...

Embodiment 3

[0055] Ti 3 C 2 -MXene-modified α-iron oxide photoelectrode, wherein the feed amount in the hydrothermal method is: Ti 3 C 2 - MXene 100mg, ferric chloride 250mg, sodium nitrate aqueous solution 1mol / L, the total volume of the reaction solution is 10mL.

[0056] The above Ti 3 C 2 -The preparation method of the α-iron oxide photoelectrode of MXene modification, comprises following preparation steps:

[0057] (1) Put Ti 3 C 2 The powder was dissolved in water (120mg / 150mL), ultrasonicated for 3 hours, and freeze-dried to obtain two-dimensional Ti 3 C 2 - MXene nanosheets;

[0058] (2) Put the FTO conductive glass in the reactor, and add ferric chloride, Ti 3 C 2 -MXene nanosheets and sodium nitrate aqueous solution;

[0059] (3) React the reactor at 150°C for 5 hours. After the reaction, take out the iron oxide and Ti deposited on the surface. 3 C 2 - MXene's FTO conductive glass, cleaned in the order of ultrapure water / absolute ethanol / ultrapure water;

[0060] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Photocurrent density | aaaaa | aaaaa |

| Photocurrent density | aaaaa | aaaaa |

| Photocurrent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com