Denitration catalyst and preparation method thereof

A denitrification catalyst and additive technology, applied in the field of denitrification catalysts, can solve problems such as complex process, single applicability of regeneration and recovery process, and difficult separation of valuable elements, so as to shorten the process flow, reduce investment and operating costs, and excellent denitrification performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

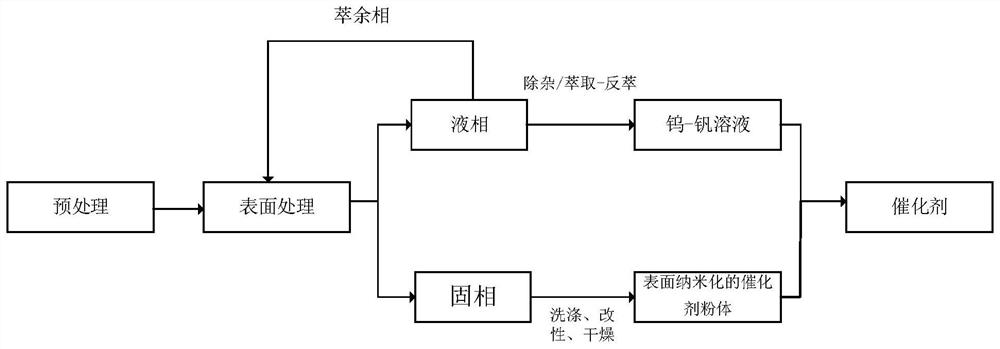

[0044] The second aspect of the present invention provides a method for preparing a denitration catalyst, wherein, as figure 1 As shown, the method includes:

[0045] (1) The waste denitration catalyst is subjected to the first impurity removal and crushing to obtain waste denitration catalyst powder;

[0046] (2) Surface treatment of the waste denitration catalyst powder with a surface treatment agent, and solid-liquid separation to obtain a solid phase and a liquid phase;

[0047] (3) After washing the solid phase, performing bulk phase modification and surface modification, and drying, to obtain a carrier material;

[0048] (4) Immerse the carrier material in an impregnation solution containing active metal components and auxiliary agents, and obtain the denitration catalyst after drying and roasting;

[0049] In step (2), the surface treatment agent is lye, the mass concentration of the lye is 6-50wt%, and the conditions of the surface treatment include: the treatment temperature i...

Embodiment 1

[0112] a) 100g of spent denitrification catalyst is cleaned, ash blown under negative pressure, then ultrasonically cleaned and dried, ball milled to 400 mesh, then 600ml of NaOH solution with a mass concentration of 30wt% is added, treated at 160℃ for 1 hour, and centrifuged , Get solid phase and liquid phase.

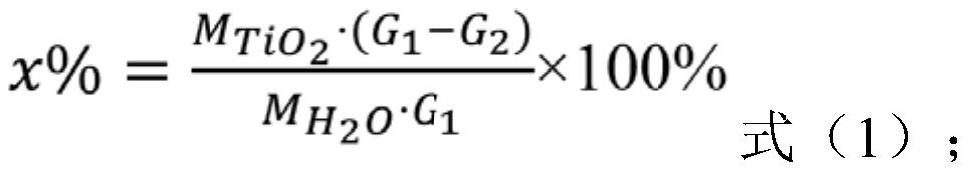

[0113] b) The solid phase in step a) was washed three times with 200ml of water, and then a 10wt% dilute sulfuric acid solution was heated and stirred at 90°C for 30 minutes, and then washed with deionized water to a conductivity of 85μs / cm. Mix and beat, then add 3wt% titanium oxysulfate and 1.5wt% silane coupling agent for stirring modification (temperature: 30°C, time: 4h), then place in an oven and dry at 120°C for 24h, and get Denitration catalyst carrier material A1, the moisture content is 7.1wt%, the specific surface area is 100m 2 / g, based on the total weight of the carrier material, the content of nano-titania whiskers is 16.8 wt%. The diameter of the nano ti...

Embodiment 2

[0121] a) 100 grams of waste denitrification catalyst is cleaned, ash blown under negative pressure, then ball milled to 400 mesh after ultrasonic cleaning and drying, and then 600ml of alkali solution is added, which contains 15wt% NaOH and 5wt% KOH , Treated at 180°C for 1 hour, centrifuged to obtain solid and liquid phases.

[0122] b) The solid phase in step a) was washed three times with 200ml of water, and then a 5wt% dilute sulfuric acid + 8wt% ammonium bisulfate solution was heated and stirred at 60°C for 30 minutes, and then washed with deionized water until the conductivity After 80μs / cm or less, mix with water and beating, then add 3wt% titanium sulfate and 1wt% silane coupling agent for stirring modification (temperature: 60℃, time: 1h), then in an oven at 120℃ After drying for 24 hours, the denitration catalyst carrier material A2 is obtained, with a water content of 8.3wt% and a specific surface area of 110m 2 / g, based on the total weight of the carrier material,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com