A photocatalytic material for highly efficient photocatalytic removal of high-concentration nitrate, its preparation method and application

A photocatalytic material and photocatalytic technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of nitrogen selective stability evaluation, low nitrate reduction efficiency, and ineffective catalytic effect Evaluation and other issues to achieve the effect of promoting photocatalytic activity, high reduction catalytic activity, and overcoming competition issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a method for preparing a photocatalytic material for highly efficient photocatalytic removal of high-concentration nitrate, including the following steps:

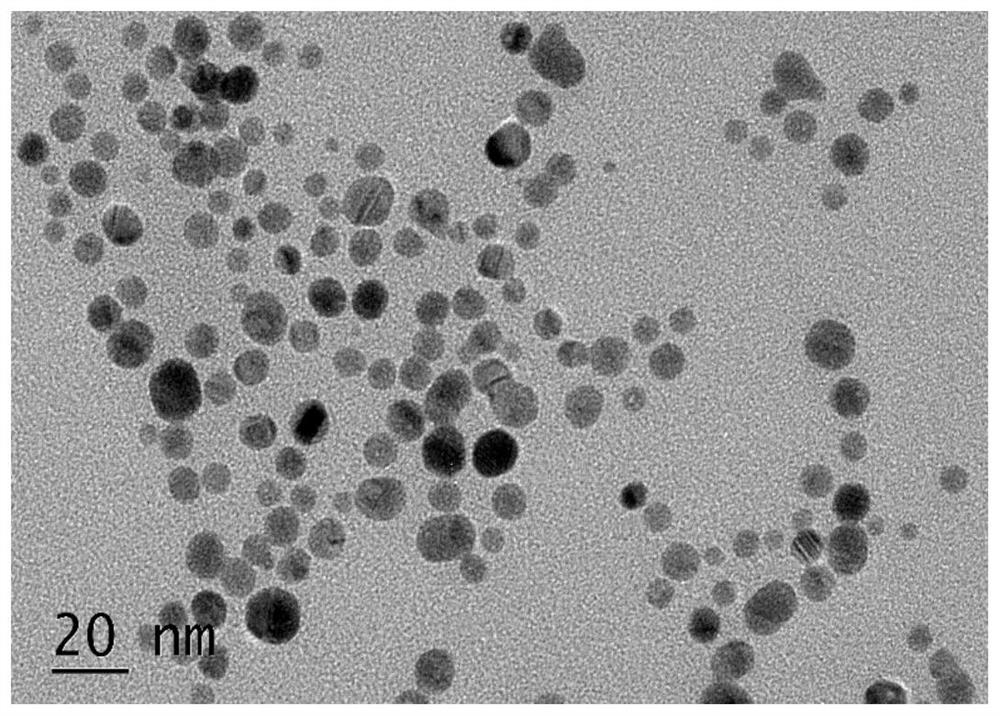

[0045] Step 1, prepare citrate-stabilized silver nanoparticles: 8mL 40mmol L -1 Sodium citrate solution as a stabilizer was added to 100mL 1mmol L -1 in the silver nitrate solution. 2ml 112mmol·L at room temperature -1 NaBH 4 Add the solution dropwise to the above mixture and stir vigorously (1000-1400rpm) to obtain a yellow-brown silver nanoparticle sol solution. Store the obtained silver sol in a refrigerator at 4°C and let it stand for 24 hours to decompose the remaining NaBH 4 , for subsequent use.

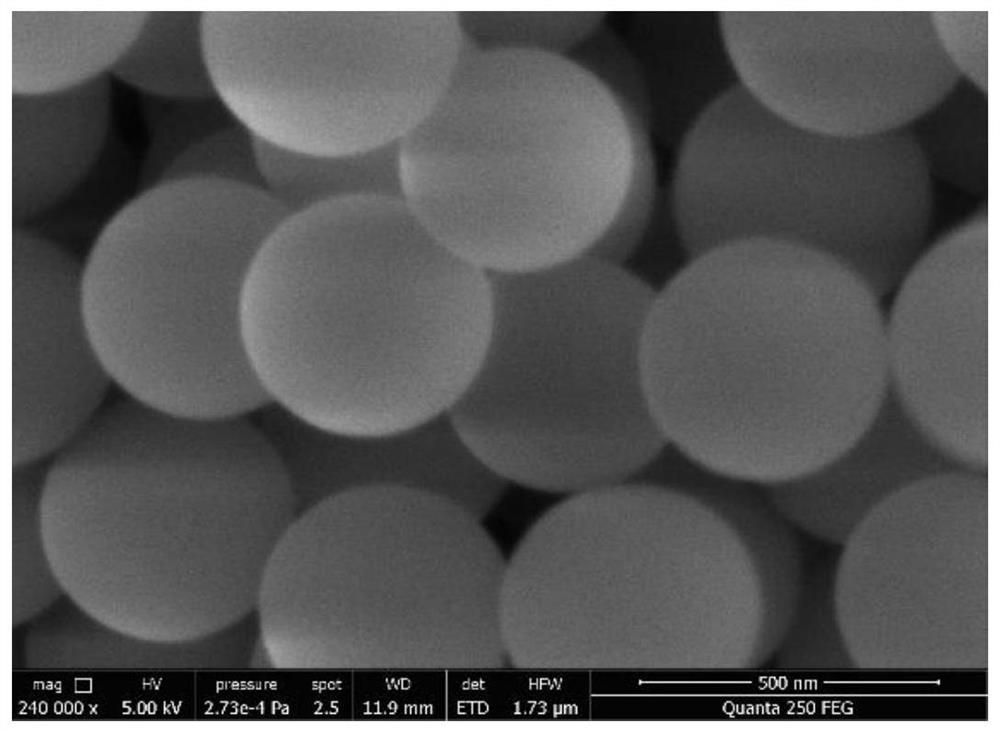

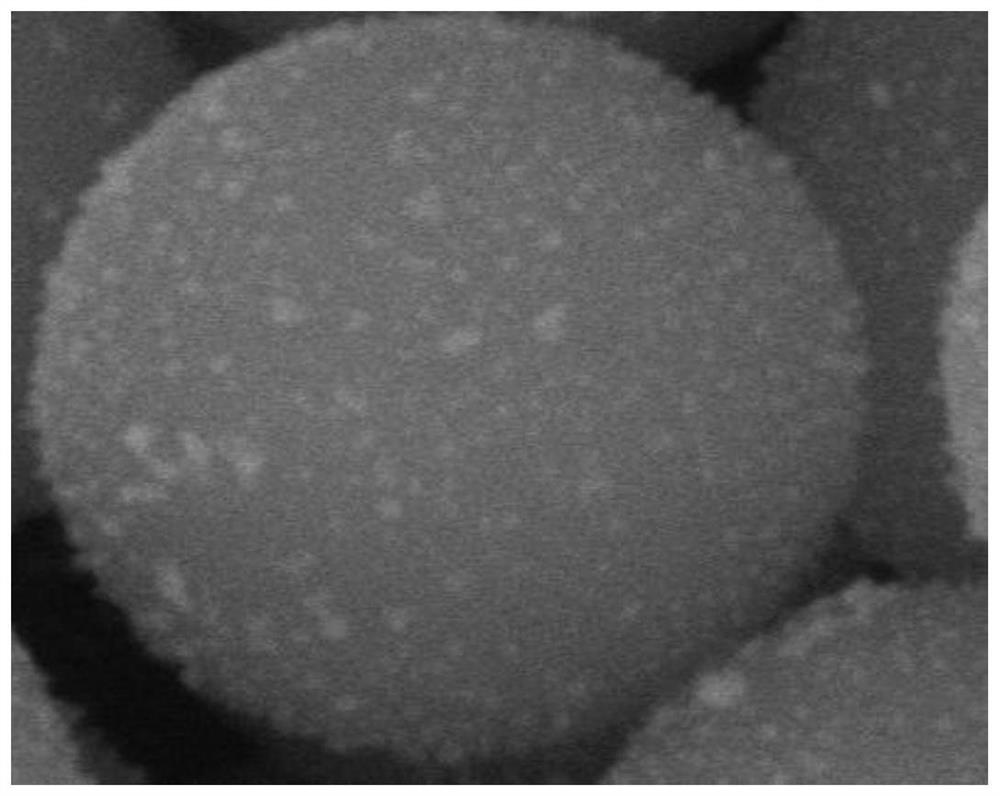

[0046] Step 2. Synthesis and functional modification of SiO 2 : Add 0.6ml of tetraethyl silicate dropwise to a mixed solution of 25mL of water, 15mL of ammonia water and 60mL of isopropanol. The reaction was continued for 30 min with vigorous stirring (1000-1400 rpm) in a 35 °C water ...

Embodiment 2

[0057] This embodiment provides a method for preparing a photocatalytic material for highly efficient photocatalytic removal of high-concentration nitrate, including the following steps:

[0058] Step 1, prepare citrate-stabilized silver nanoparticles: 8mL 40mmol L -1 Sodium citrate solution as a stabilizer was added to 100mL 1mmol L -1 in the silver nitrate solution. 2ml 112mmol·L at room temperature -1 NaBH 4 Add the solution dropwise to the above mixture and stir vigorously (1000-1400rpm) to obtain a yellow-brown silver nanoparticle sol solution. Store the obtained silver sol in a refrigerator at 4°C and let it stand for 24 hours to decompose the remaining NaBH 4 , for subsequent use.

[0059] Step 2. Synthesis and functional modification of SiO 2 : Add 0.6ml of tetraethyl silicate dropwise to a mixed solution of 25mL of water, 15mL of ammonia water and 60mL of isopropanol. The reaction was continued for 30 min with vigorous stirring (1000-1400 rpm) in a 35 °C water ...

Embodiment 3

[0067] This embodiment provides a method for preparing a photocatalytic material for highly efficient photocatalytic removal of high-concentration nitrate, including the following steps:

[0068] Step 1, prepare citrate-stabilized silver nanoparticles: 8mL 40mmol L -1 Sodium citrate solution as a stabilizer was added to 100mL 1mmol L -1 in the silver nitrate solution. 2ml 112mmol·L at room temperature -1 NaBH 4 Add the solution dropwise to the above mixture and stir vigorously (1000-1400rpm) to obtain a yellow-brown silver nanoparticle sol solution. Store the obtained silver sol in a refrigerator at 4°C and let it stand for 24 hours to decompose the remaining NaBH 4 , for subsequent use.

[0069] Step 2. Synthesis and functional modification of SiO 2 : Add 0.6ml of tetraethyl silicate dropwise to a mixed solution of 25mL of water, 15mL of ammonia water and 60mL of isopropanol. The reaction was continued for 30 min with vigorous stirring (1000-1400 rpm) in a 35 °C water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com