Method for repairing defects of lap joint positions of adjacent sub-areas formed by selective laser melting

A technology of laser selective melting and lap joint position, which is applied in the field of additive manufacturing engineering to achieve the effect of eliminating molten pool defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1—Single-layer printing

[0024] (1) Use IN718 spherical powder, powder diameter 15-53um, fluidity 16s / 50g, D 50 32um, the substrate of laser selective melting equipment is preheated to 80°C for single-layer printing.

[0025] (2) The printing process is carried out in a protective atmosphere of Ar gas, and the oxygen content in the cabin is controlled below 200ppm.

[0026] (3) The parameters of laser selective melting are: laser power 195W, powder coating thickness 30um, substrate preheating temperature 80°C, scanning line spacing 70um, scanning strategy is laser bidirectional scanning, no strip overlap; scanning speed is 800mm / s, 900mm / s, 1000mm / s, 1100mm / s, 1200mm / s, 1300mm / s.

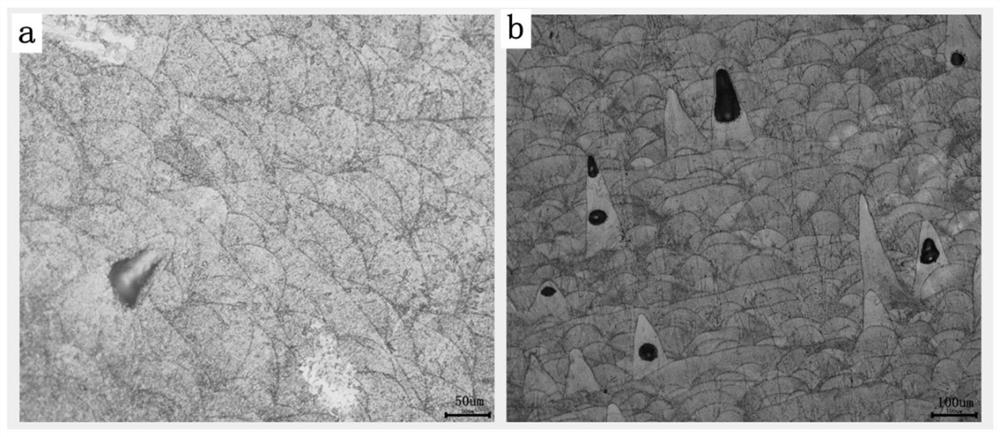

[0027] (4) Clean the substrate containing a single-layer printing layer with alcohol and place it under a microscope to observe the uniformity between the end of the melt channel and the inside of the melt, as shown in Figure 4 As shown, when the scanning speed is 800mm / s, 900m...

Embodiment 2

[0028] Example 2—Block Printing

[0029] (1) Using the materials and equipment used in Example 1, and the process parameters for single-layer printing, a 10x10x10mm IN718 block was printed.

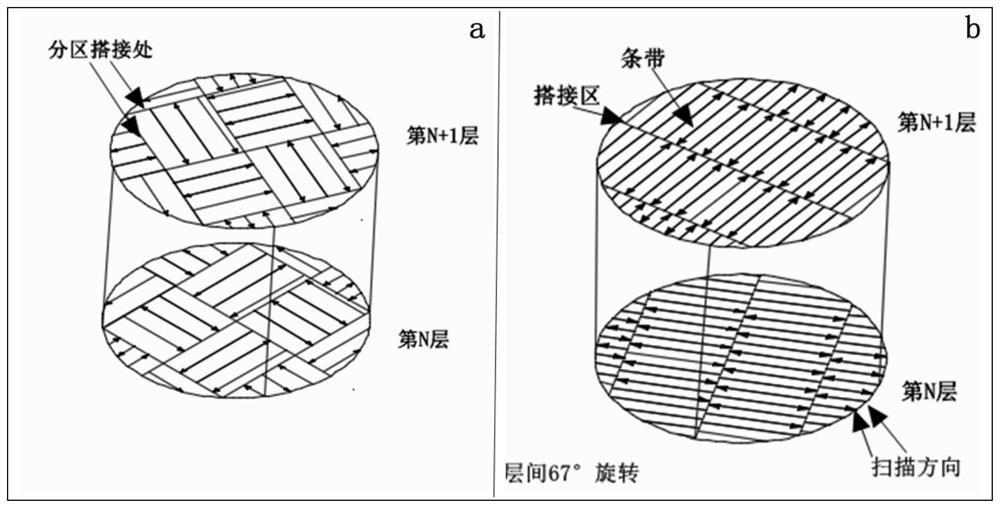

[0030] (2) Slice the formed parts with a thickness of 30um, plan the scanning path of the components, adopt strip-type bidirectional laser scanning, and set the laser jump speed of adjacent melting channels to 3000mm / s.

[0031] (3) The parameters of laser selective melting are: laser power 195W, powder coating thickness 30um, substrate preheating temperature 80°C, scanning line spacing 70um, interlayer rotation 67°, laser scanning speed 1000mm / s.

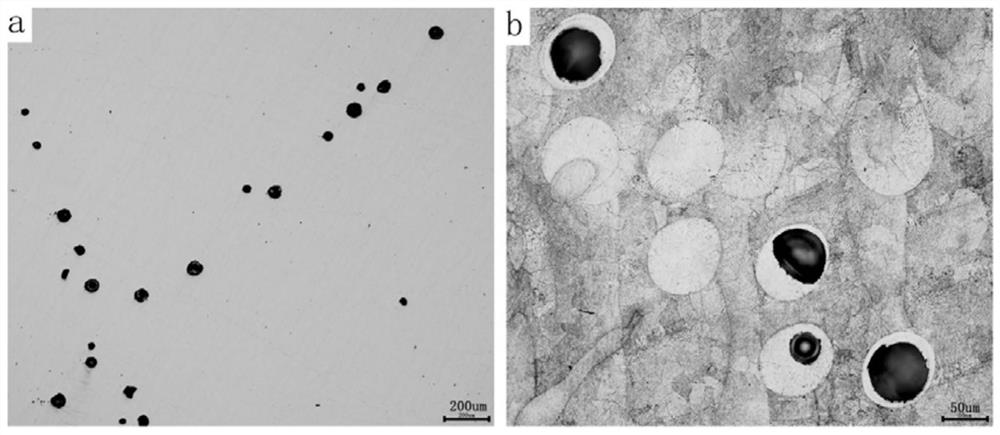

[0032] (4) The printed IN718 test block was removed from the substrate by wire cutting, and after ultrasonic cleaning, the density of the block was determined to be 99.0% by the Archimedes drainage method. Use wire cutting to cut the over-dense block along the forming direction and perpendicular to the forming direction in turn, and conduct m...

Embodiment 3

[0034] Example 3—Block Printing

[0035] (1) Using the materials and equipment used in Example 1, and the process parameters for single-layer printing, a 10x10x10mm IN718 block was printed.

[0036] (2) Slice the formed parts with a thickness of 30um, plan the scanning path of the components, adopt strip-type bidirectional laser scanning, and set the laser jump speed of adjacent melting channels to 4000mm / s.

[0037] (3) The parameters of laser selective melting are: laser power 195W, powder coating thickness 30um, substrate preheating temperature 80°C, scanning line spacing 70um, interlayer rotation 67°, laser scanning speed 1000mm / s.

[0038] (4) The printed IN718 test block was removed from the substrate by wire cutting, and after ultrasonic cleaning, the density of the block was determined to be 99.4% by the Archimedes drainage method. Use wire cutting to cut the over-dense block along the forming direction and perpendicular to the forming direction in turn, and conduct m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com