Extinction material used for BOPE extinction film, preparation method for extinction material and BOPE extinction film

A matting film and masterbatch technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of uneven mixing and dispersion of polyethylene and polypropylene, precipitation of die heads, short production cycle, etc. , to achieve the effect of improving matting effect, strong fluidity and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

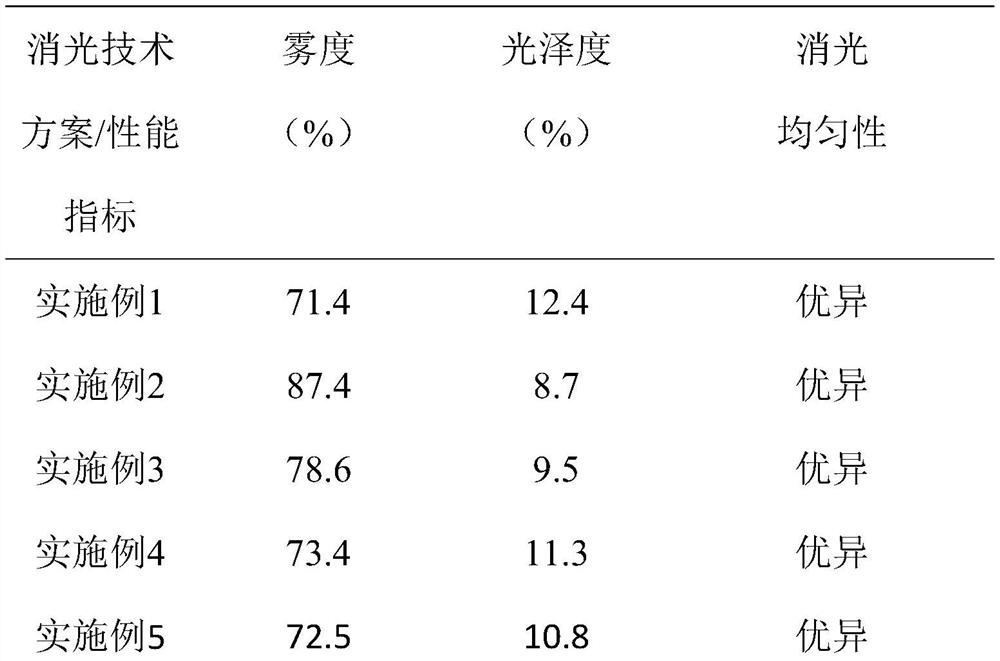

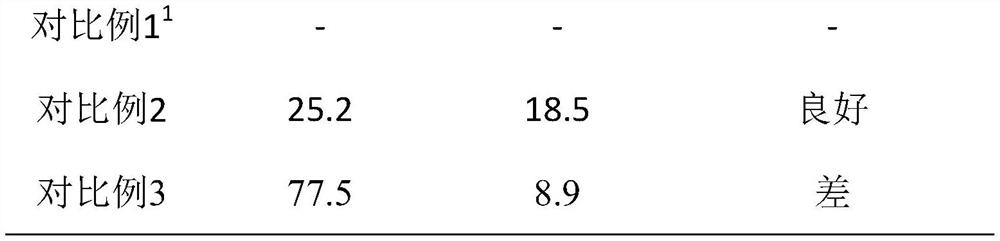

Examples

preparation example Construction

[0020] The invention provides a matting material for a BOPE matting film, a preparation method thereof, and a BOPE matting film, which have good film-forming effect and uniform matting effect, and the technical scheme is as follows.

[0021] The invention provides a matting material for BOPE matting film. The matting material for BOPE matting film includes copolymerized polyethylene, polypropylene, masterbatch A and masterbatch B; the masterbatch A includes a masterbatch matrix and hydrogenated petroleum resin ; The masterbatch B includes a masterbatch matrix and a PPA processing aid; the masterbatch matrix is copolymerized polyethylene.

Embodiment approach

[0022] As a preferred embodiment, the matting material for the BOPE matting film includes copolymerized polyethylene, polypropylene, masterbatch A, masterbatch B and anti-oxidation masterbatch.

[0023] As an embodiment, the copolymerized polyethylene includes one or more of binary copolymers and terpolymers. The binary copolymer includes a copolymerized polyethylene formed by copolymerization of 1-propylene, 1-butene, 1-hexene or 1-octene with ethylene, and also includes ethylene-vinyl acetate copolymer, ethylene-acrylic acid Copolymer, ethylene-methyl acrylate copolymer, ethylene-ethyl acrylate copolymer, ethylene-butyl acrylate copolymer. The terpolymers include ethylene-propylene-butene terpolymers. The melt index range of the copolymerized polyethylene is 10-50g / 10min (190°C, 2.16kg).

[0024] As an embodiment, the polypropylene includes one or more of homopolypropylene and copolymerized polypropylene. The copolymerized polypropylene includes binary copolymers of propy...

Embodiment 1

[0035] Embodiment 1 provides a matting material for BOPE matting film, including 40% copolymerized polyethylene, 35% polypropylene, 10% masterbatch A, 10% masterbatch B, and 5% anti-oxidation masterbatch. The copolymerized polyethylene is polyethylene copolymerized with ethylene and butene, with a melt index of 10 g / 10 min (190° C., 2.16 kg). The polypropylene is an ethylene-propylene binary copolymer with a melt index of 3g / 10min (230°C, 2.16kg). The crystallization temperature of polypropylene is 5°C higher than that of copolymerized polyethylene. The masterbatch A includes 60% masterbatch matrix and 40% hydrogenated petroleum resin, and the masterbatch matrix is copolymerized polyethylene. The masterbatch B includes 97% masterbatch matrix and 3% PPA processing aid, the masterbatch matrix is copolymerized polyethylene, and the PPA processing aid is a commercially available fluorine-containing elastomer. The antioxidant masterbatch includes 90% masterbatch matrix and 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap