Antistatic leather finishing agent as well as preparation method and application thereof

A leather finishing agent and antistatic technology, which is applied in application, conductive coatings, leather surface treatment, etc., can solve the problems of application limitations and the decline of mechanical properties of composite materials, so as to avoid agglomeration, facilitate film formation, and improve system stability The effect of sex and film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention discloses a preparation method of an antistatic leather finishing agent, which comprises the following steps:

[0035] (1) Preparation of Ti 3 C 2 Dispersion: Weigh 0.32g of LiF, add it into 4mL of concentrated hydrochloric acid (9mol / L), stir the mixture magnetically for 10min to fully dissolve LiF. Slowly add 0.2g of Ti in 10min 3 AlC 2 powder to avoid excessive initial temperature of the solution due to exothermic reaction. The reaction mixture was then magnetically stirred at 35 °C for 48 h. Wash the acidic product by centrifugation with deionized water, clear the supernatant of the water sample, add water and continue centrifugation until the pH value of the supernatant reaches about 6. The solid residue was dispersed in water, and nitrogen gas (N 2 ) under the condition of ultrasonication for 1h, followed by centrifugation, and the dark green supernatant was taken, and this was repeated three times to obtain Ti-containing 3 C 2 Nanosheet Ti ...

Embodiment 1

[0052] (1) Preparation of Ti 3 C 2 Dispersion: Weigh 0.32g of LiF, add it into 4mL of concentrated hydrochloric acid (9mol / L), stir the mixture magnetically for 10min to fully dissolve LiF. Slowly add 0.2g of Ti in 10min 3 AlC 2 powder to avoid excessive initial temperature of the solution due to exothermic reaction. The reaction mixture was then magnetically stirred at 35 °C for 48 h. The acidic product was washed by centrifugation with deionized water, the supernatant of the water sample was cleared, and water was added to continue centrifugation until the pH value of the supernatant reached 6. The solid residue was dispersed in water, and nitrogen gas (N 2 ) under the condition of ultrasonication for 1h, followed by centrifugation, and the dark green supernatant was taken, and this was repeated three times to obtain Ti-containing 3 C 2 Nanosheet Ti 3 C 2 Dispersions.

[0053] (2) Put Ti 3 C 2 The dispersion liquid was rotary evaporated to a concentration of 1.4%...

Embodiment 2

[0063] Adopt the method as described in embodiment 1 to prepare containing Ti 3 C 2 Nanosheet Ti 3 C 2 Dispersions.

[0064] Ti 3 C 2 The dispersion liquid was rotary evaporated to a concentration of 1.4%, and 20 g of the dispersion liquid was vacuum-filtered with a filter membrane of 450 nm to obtain Ti 3 C 2 The initial film, the resulting Ti 3 C 2 The initial film is torn off. Coat 4mol / L hydrazine hydrate on the ceramic sheet, and then apply Ti 3 C 2 The film is suspended on the hydrazine hydrate coating, covered with another ceramic sheet, put the whole into a closed container, keep warm in an oven at 80°C for 2 hours, take it out and place it in a fume hood to stand until the reaction residue volatilizes to obtain Hydrophobic Ti 3 C 2 film.

[0065] 0.03g hydrophobic Ti 3 C 2 The film was ultrasonically dispersed in 6mL water for 30min to obtain hydrophobic Ti 3 C 2 nanosheet dispersion. Uniformly disperse dopamine (DA) in the buffer solution of Tris h...

PUM

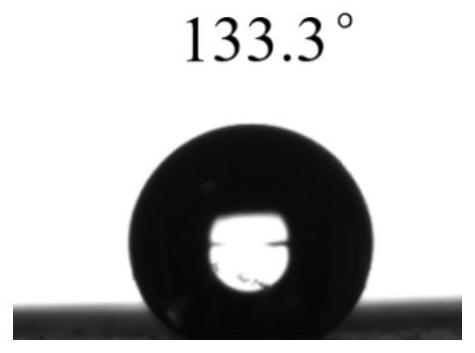

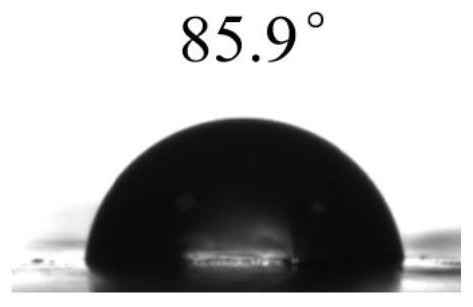

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

| Surface resistivity | aaaaa | aaaaa |

| Surface resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com