Circulating fluidized bed gasification device and method for cooperatively treating waste liquid

A circulating fluidized bed and gasification device technology, which is applied in the gasification of granular/powdered fuels, the manufacture of combustible gases, and the petroleum industry. It can solve problems such as short service life, increased carbon dioxide content in gas, and short burner life. Achieve the effects of reducing cost and difficulty, increasing carbon conversion rate, and improving gasification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065]In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

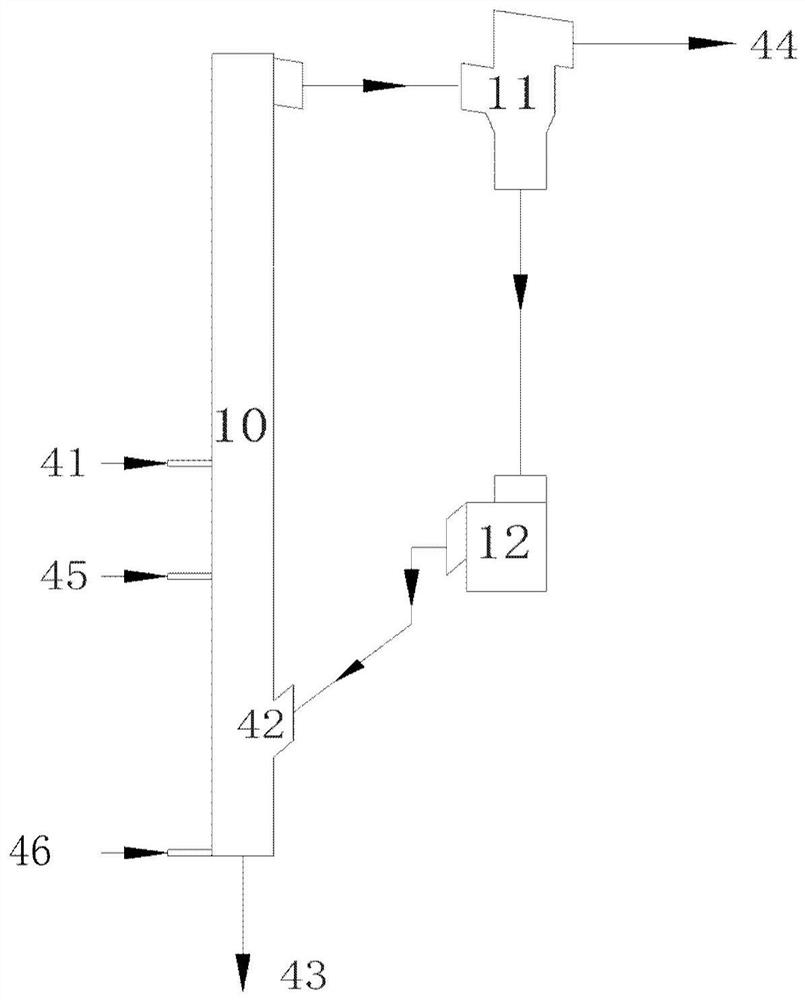

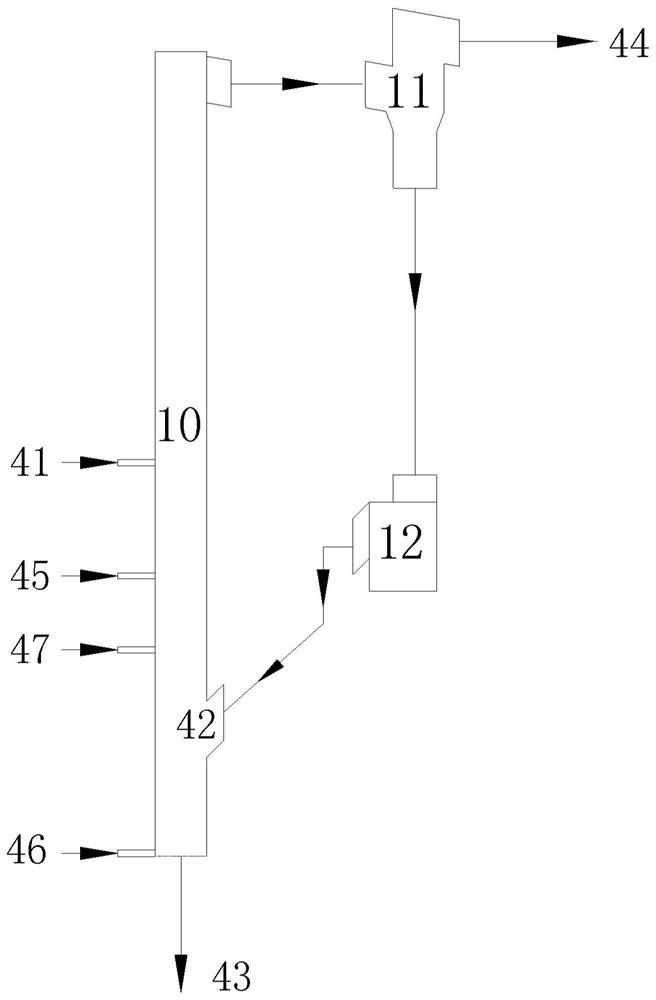

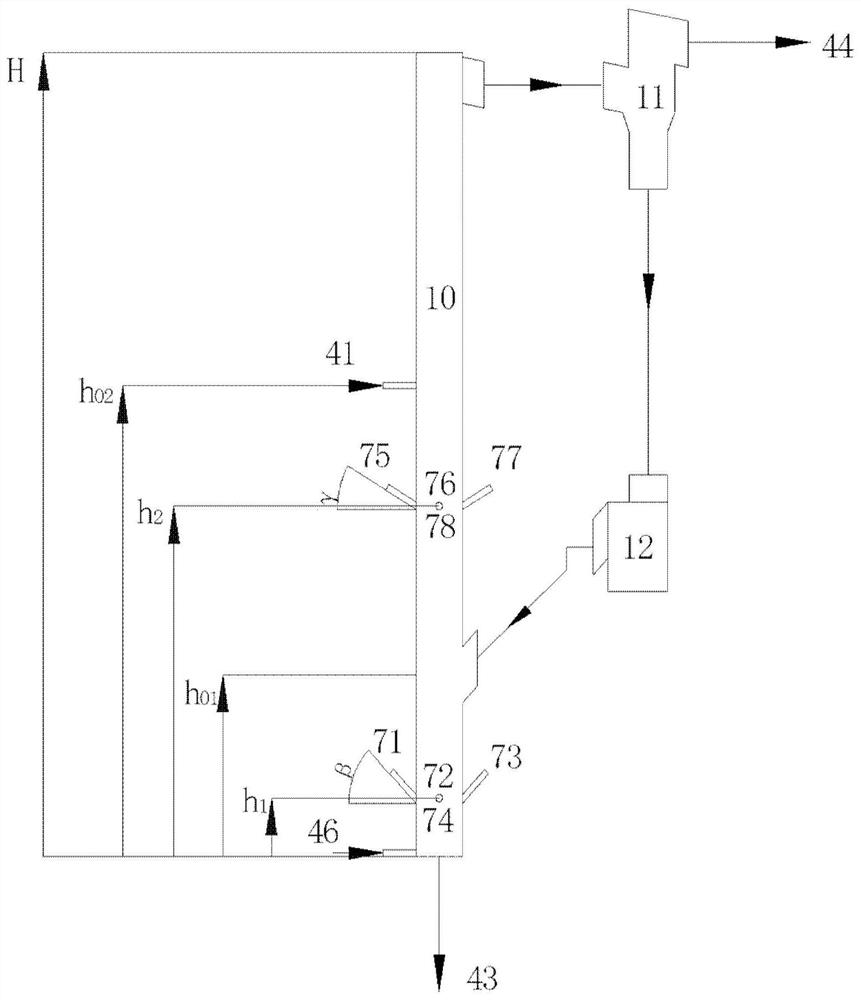

[0066] The invention discloses a circulating fluidized bed gasification device for co-processing waste liquid, which includes a gasification furnace, and the gasification furnace is provided with a first waste liquid and auxiliary gasification agent inlet unit and a second waste liquid and auxiliary gasification agent inlet unit; the first waste liquid and auxiliary gasification agent inlet unit and the second waste liquid and auxiliary gasification agent inlet unit are arranged at different height positions of the gasifier.

[0067] In some embodiments of the present invention, the gasifier further includes a return port, and the height h of the return port from the bottom of the gasifier furnace is 01 for:

[0068] h 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com