Anti-oxidation lubricating oil and preparation method thereof

A lubricating oil and anti-oxidation technology, which is applied in the field of lubricating oil, can solve problems such as lubricating oil oxidation, achieve the effects of improving anti-oxidation stability, reducing the difficulty of oil film formation, and improving anti-oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

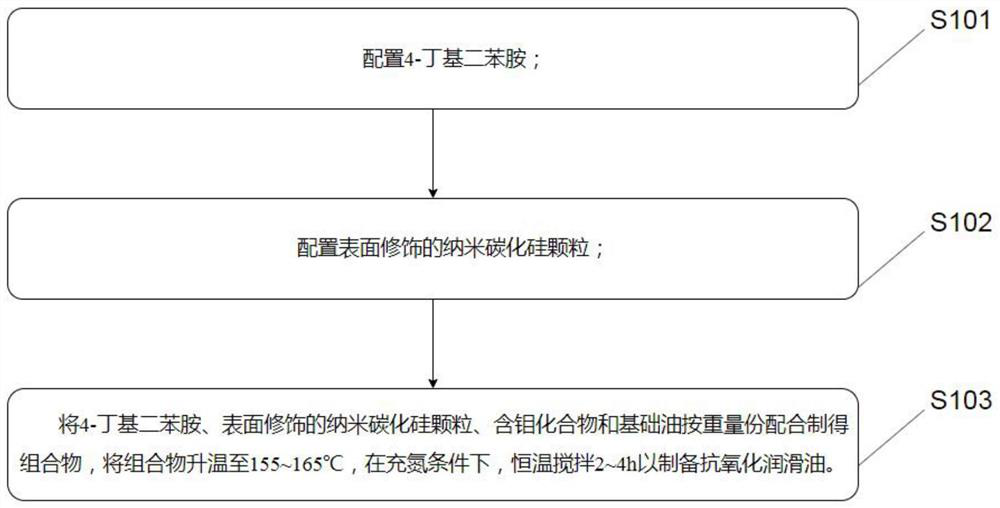

[0035] A method for preparing an anti-oxidation lubricating oil, comprising the above-mentioned anti-oxidation lubricating oil, is characterized in that it also includes the following steps:

[0036] S101 configuration 4-butyl diphenylamine;

[0037] S102 configures surface-modified nano-silicon carbide particles;

[0038] S103 Mix 4-butyldiphenylamine, surface-modified nano-silicon carbide particles, molybdenum-containing compounds and base oil in parts by weight to prepare a composition, raise the temperature of the composition to 155-165°C, and stir at constant temperature under nitrogen filling conditions 2 to 4 hours to prepare anti-oxidation lubricating oil.

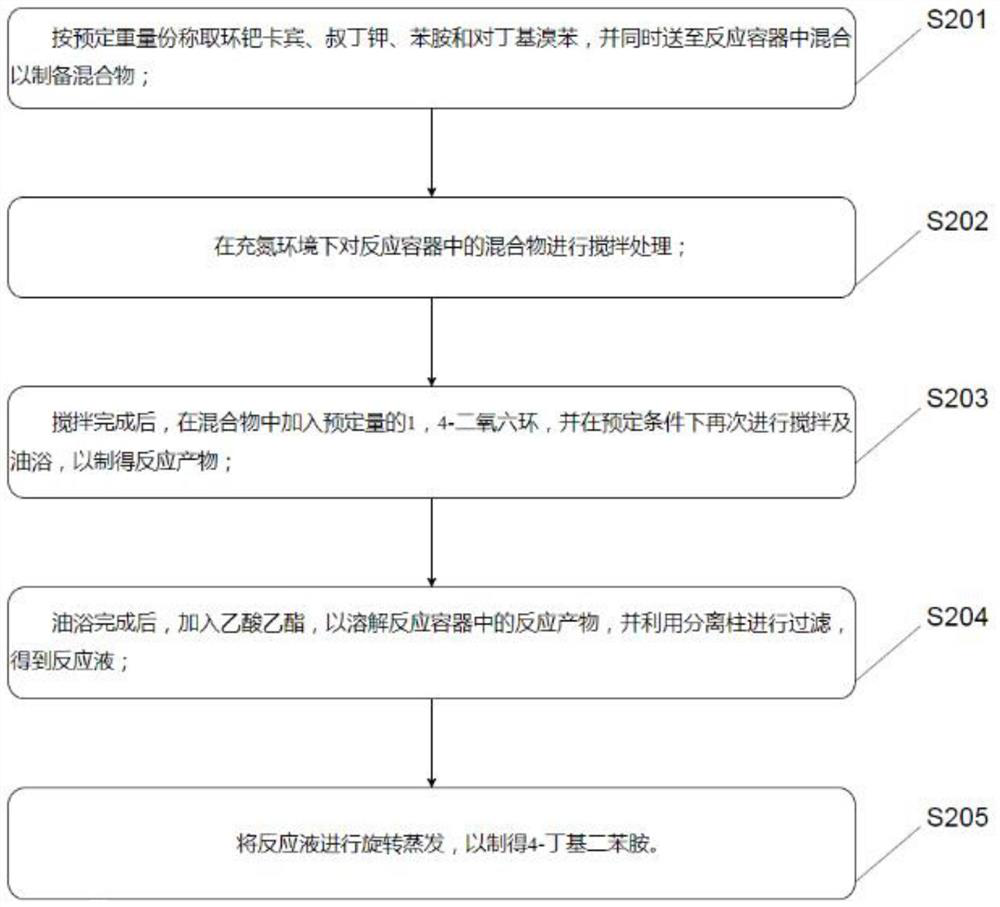

[0039] Further, the configuration of 4-butyldiphenylamine comprises the following steps:

[0040] S201 Weigh palladium carbene, tert-butyl potassium, aniline and p-butylbromobenzene in predetermined weight parts, and simultaneously send them to the reaction vessel for mixing to prepare a mixture;

[0041] S202 S...

specific Embodiment 1

[0050] S401 prepares 4-butyldiphenylamine, weighs 2 parts of palladium carbene, 100 parts of tert-butyl potassium, 70 parts of aniline and 150 parts of p-butylbromobenzene in predetermined weight parts and sends them to a reaction vessel for mixing to prepare a mixture;

[0051] S402 Stir the mixture in the reaction vessel for 45min under a nitrogen-filled environment;

[0052] S403 After the stirring is completed, 5 parts of 1,4-dioxane are added to the mixture, and the temperature is raised to 110° C. After stirring for 30 minutes, the reaction vessel is bathed in oil for 3 hours;

[0053] S404 After the oil bath is completed, let the reaction vessel cool to room temperature, add ethyl acetate to dissolve the reaction product in the reaction vessel, and filter with a separation column to obtain a reaction solution;

[0054] S405 Control the reaction solution at 25° C. for rotary evaporation to prepare 4-butyldiphenylamine.

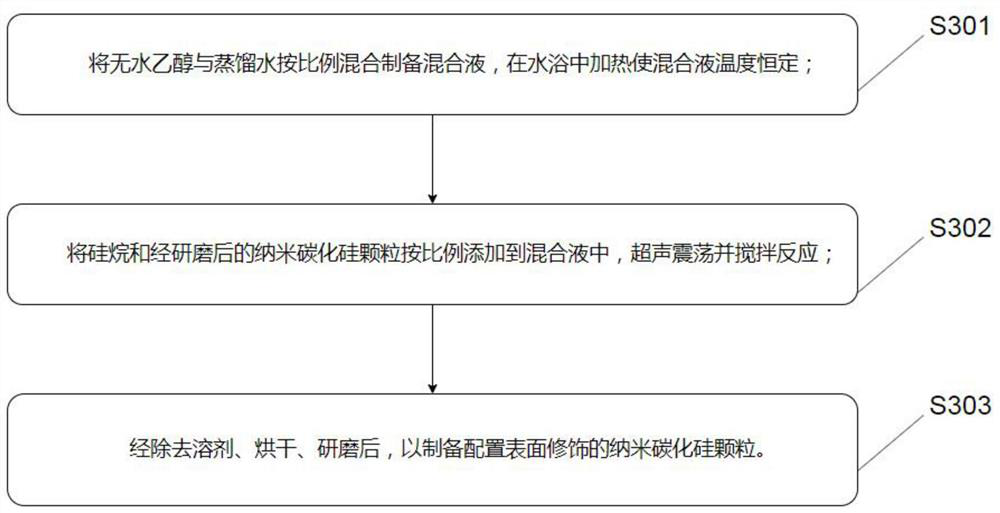

[0055] S501 Prepare nano-silicon carbide particle...

specific Embodiment 2

[0060] S601 prepares 4-butyldiphenylamine, weighs 3 parts of palladium carbene, 120 parts of tert-butyl potassium, 80 parts of aniline and 160 parts of p-butylbromobenzene in predetermined weight parts and sends them to a reaction vessel for mixing to prepare a mixture;

[0061] S602 Stir the mixture in the reaction vessel for 45min under a nitrogen-filled environment;

[0062] S603 After the stirring is completed, add 10 parts of 1,4-dioxane to the mixture, and raise the temperature to 110°C, stir for 30 minutes, and put the reaction vessel in an oil bath for 3 hours;

[0063] S604 After the oil bath is completed, allow the reaction vessel to cool to room temperature, add ethyl acetate to dissolve the reaction product in the reaction vessel, and filter through a separation column to obtain a reaction solution;

[0064] S605 Control the reaction solution at 25° C. for rotary evaporation to prepare 4-butyldiphenylamine.

[0065] S701 Prepare nano-silicon carbide particles, mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com