Device and method for improving defects of cladding layer based on eddy current induction technology

A technology of eddy current induction and cladding layer, which is applied in the direction of coating, metal material coating process, etc., to achieve the effect of strong controllability, improved performance and easy operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

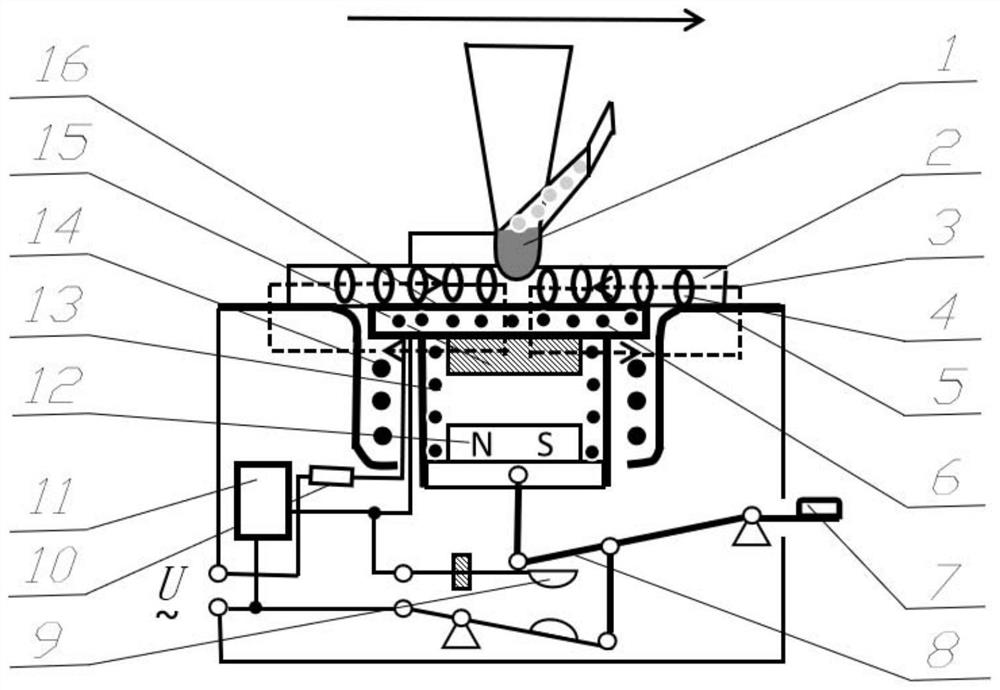

Method used

Image

Examples

Embodiment 1

[0056] Clean the upper surface area of H13 die steel.

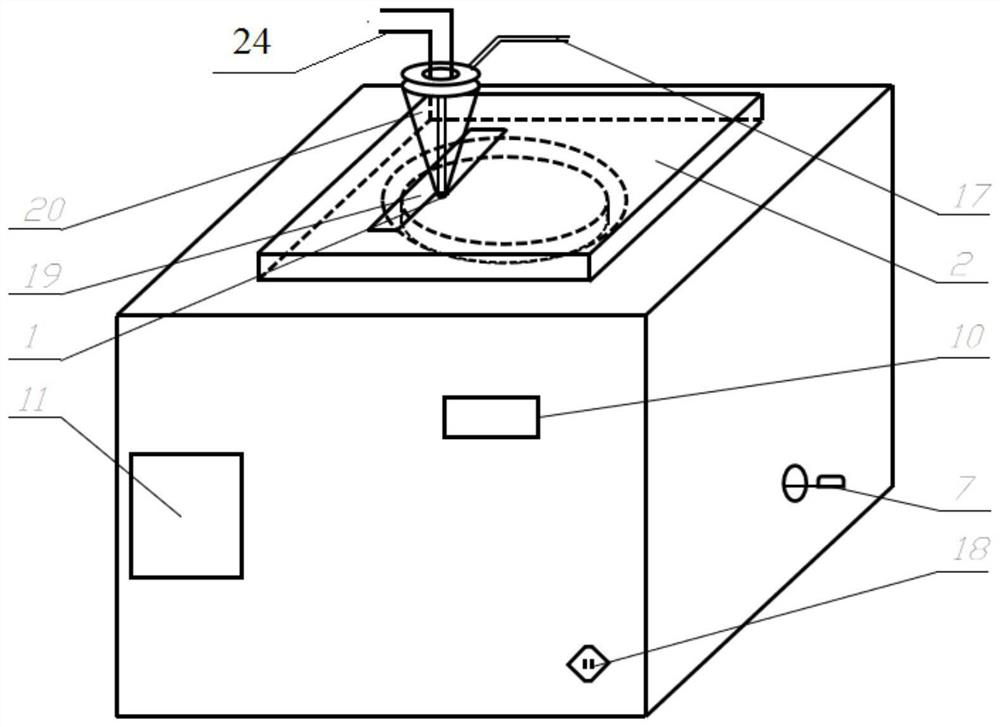

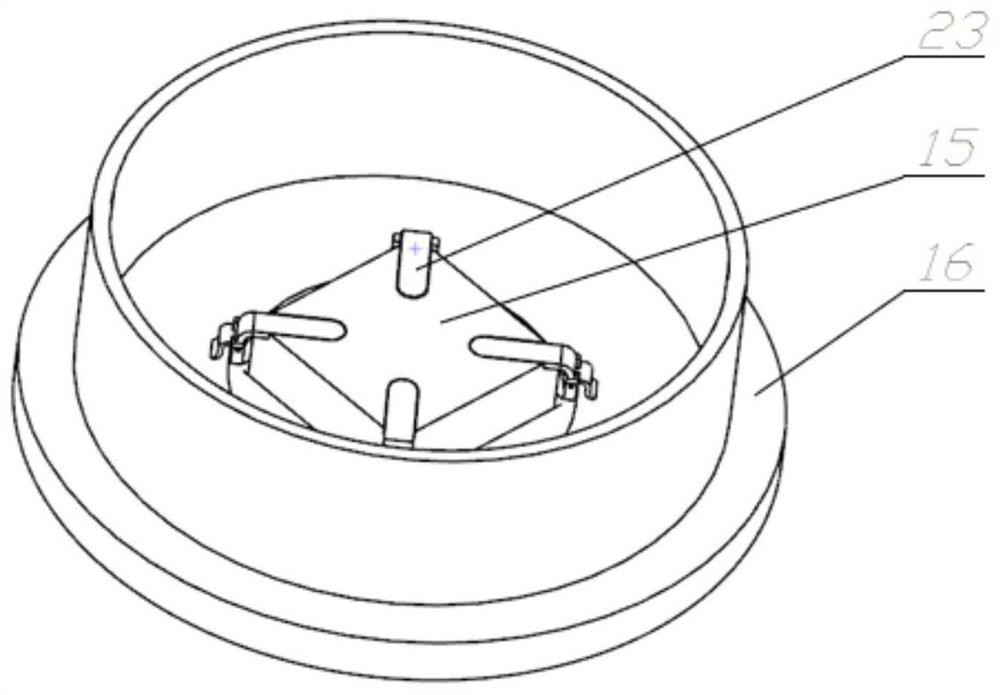

[0057] Fix the device horizontally in the cladding equipment, and fix the H13 mold steel with dimensions of 150×150×12 mm in length, width and height respectively on the workbench 5 of the device, and make its upper surface within the range of the heating device 16 .

[0058] Set the path of the laser beam to be S-shaped on the computer-related software, the scanning speed is 10mm / s, the laser power is 300W, the spot diameter is 1mm, the overlap rate is 50%, the protective gas flow rate is 2.0L / min, and the For the cladding equipment, the laser beam 24 is vertically irradiated on the upper surface area of the H13 mold steel, and the height of the nozzle 20 is adjusted so that the focal point is located on the upper surface of the H13 mold steel, and the travel path does not exceed the range of the heating device 16 .

[0059] Before cladding, the plug 18 of the device is powered on first, and then the toggle switch 17...

Embodiment 2

[0066] Clean the upper surface area of 45 steel.

[0067] Fix the device horizontally in the cladding equipment, and fix 45 steel with dimensions of 150×150×12 mm in length, width and height respectively on the workbench 5 of the device, and make its upper surface within the range of the heating device 16 .

[0068]Set the path of the laser beam to be S-shaped on the computer-related software, the scanning speed is 10mm / s, the laser power is 300W, the spot diameter is 1mm, the overlap rate is 50%, the protective gas flow rate is 2.0L / min, and the For the cladding equipment, the laser beam 24 is vertically irradiated on the upper surface area of 45 steel, and the height of nozzle 20 is adjusted to make the focal point on the upper surface of 45 steel, and ensure that the traveling path does not exceed the range of the heating device.

[0069] Before cladding, the plug 18 of the device is powered on first, and then the toggle switch 17 is pressed, and the permanent magnet 12...

Embodiment 3

[0076] Clean the upper surface area of 304 stainless steel.

[0077] Fix the device horizontally in the cladding equipment, and fix 304 stainless steel with dimensions of 150×150×12 mm in length, width and height respectively on the workbench 5 of the device, and make its upper surface within the range of the heating device 16 .

[0078] Set the path of the laser beam to be S-shaped on the computer-related software, the scanning speed is 10mm / s, the laser power is 300W, the spot diameter is 1mm, the overlap rate is 50%, the protective gas flow rate is 2.0L / min, and the For the cladding equipment, 24 laser beams are vertically irradiated on the upper surface area of 304 stainless steel, and the height of nozzle 20 is adjusted to make the focal point on the upper surface of 304 stainless steel, and ensure that the walking path does not exceed the range of heating device 16.

[0079] Before cladding, the plug 18 of the device is powered on first, and then the toggle switch 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com