Composite diaphragm for lithium metal secondary battery and preparation method and application of composite diaphragm

A composite separator and secondary battery technology, applied in the field of electrochemical power supply, can solve the problems of harsh operating environment, easy generation of lithium dendrites, piercing the separator, etc., to simplify the process, promote uniform deposition, and improve the effect of dendrite problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

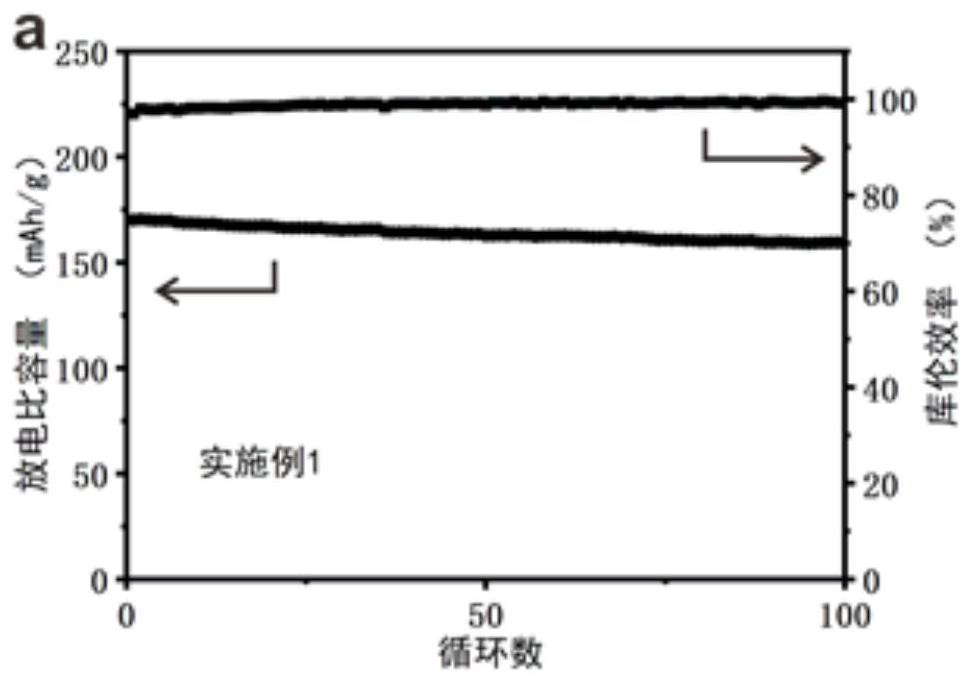

[0045] This example is used to illustrate the preparation of the composite diaphragm of the present invention and its application in nickel-cobalt lithium manganate (NCM622) batteries

[0046] (1) Mix polyvinylidene fluoride (mass fraction 2wt.%), magnesium nitride particles (particle size is about 200nm, mass fraction 20wt.%) and N-methylpyrrolidone, and perform high-energy ball milling at a speed of 450rpm and ball milling time 4 Hour. After mixing, the solution was knife-coated on the surface of a commercial polyethylene separator with a spatula with a gap of 1 μm. Place the diaphragm at 50°C for drying treatment to obtain a composite diaphragm coated with magnesium nitride on the surface.

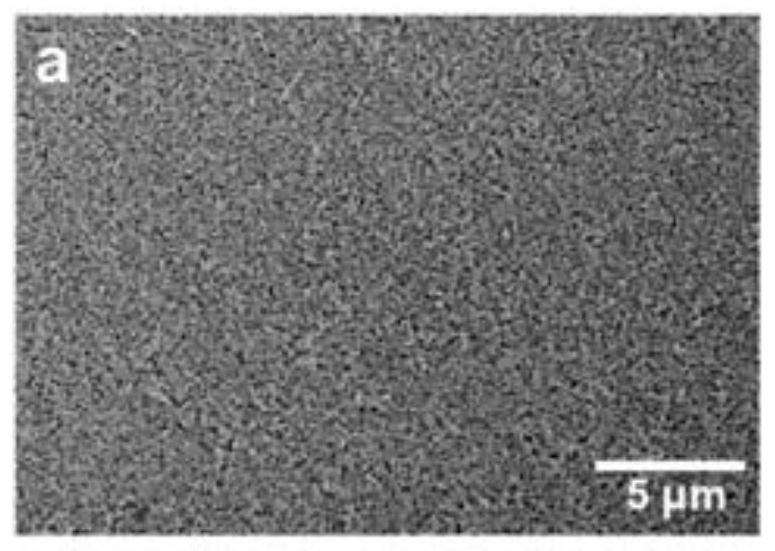

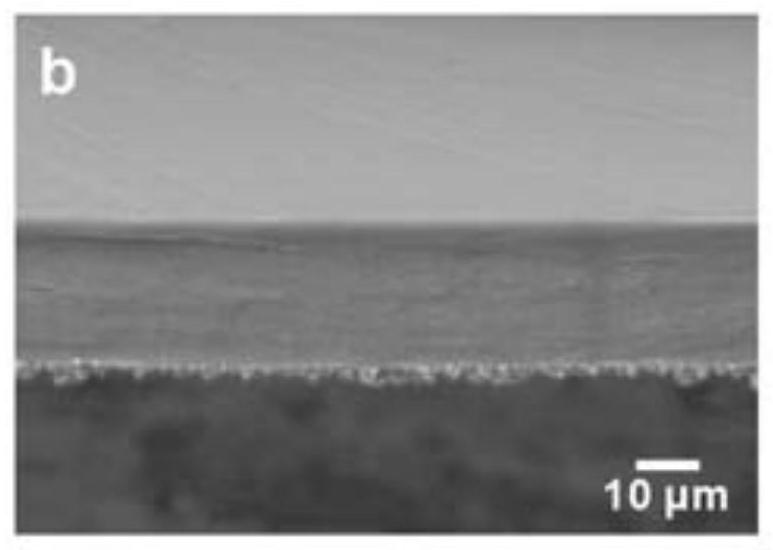

[0047] Figure 1(a) is a scanned image of the topography of the side coated with magnesium nitride, and Figure 1(b) is a scanned image of the cross-section of the composite diaphragm. It can be seen from Figure a that the magnesium nitride particles are evenly coated on the surface of ...

Embodiment 2

[0054] The composite diaphragm and battery were prepared in the same manner as in Example 1, except that the particle diameter of the coating active material used in step (1) was about 50 nm.

Embodiment 3

[0056] Composite separators and batteries were prepared in the same manner as in Example 1, except that the coating active material used in step (1) had a particle size of about 1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com