Lip glaze and preparation method thereof

A lip glaze and emollient technology, applied in the field of lip make-up, can solve the problems of poor adhesion, poor overall applicability, inconvenience, etc., and achieve the effect of reducing the probability of shedding and migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

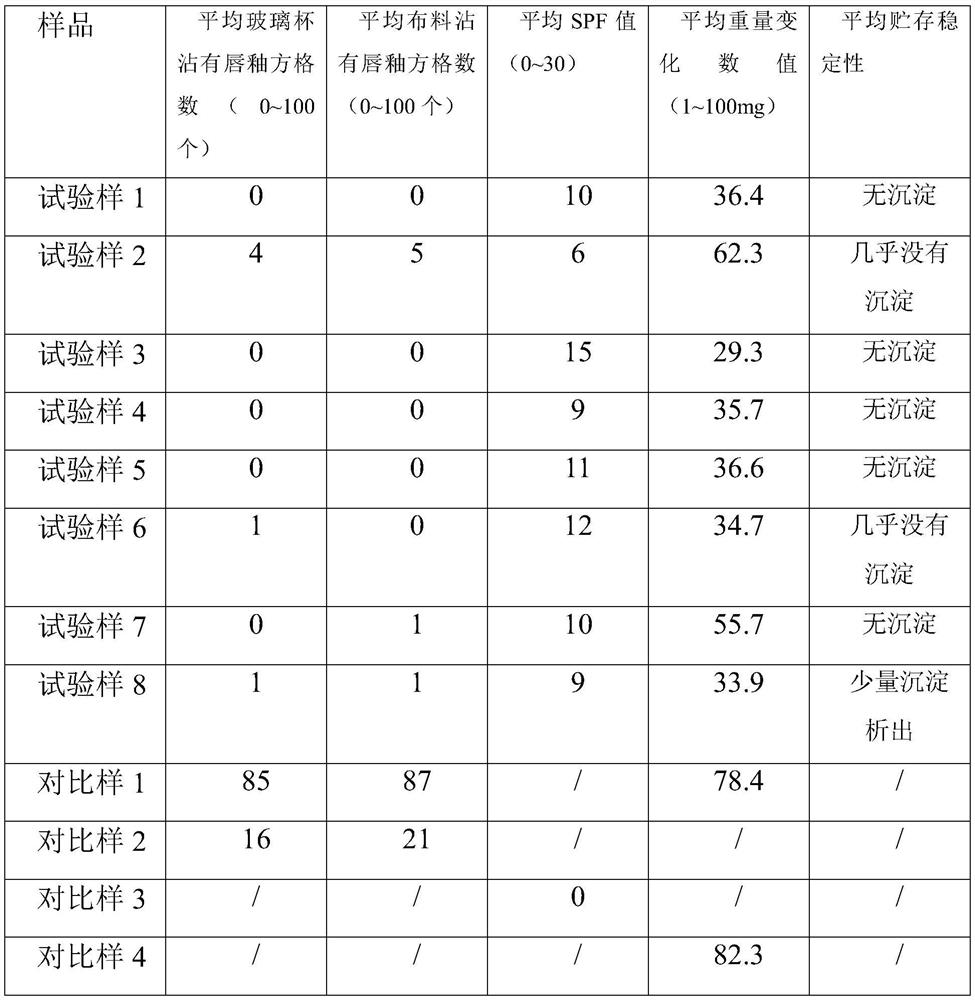

Examples

Embodiment 1

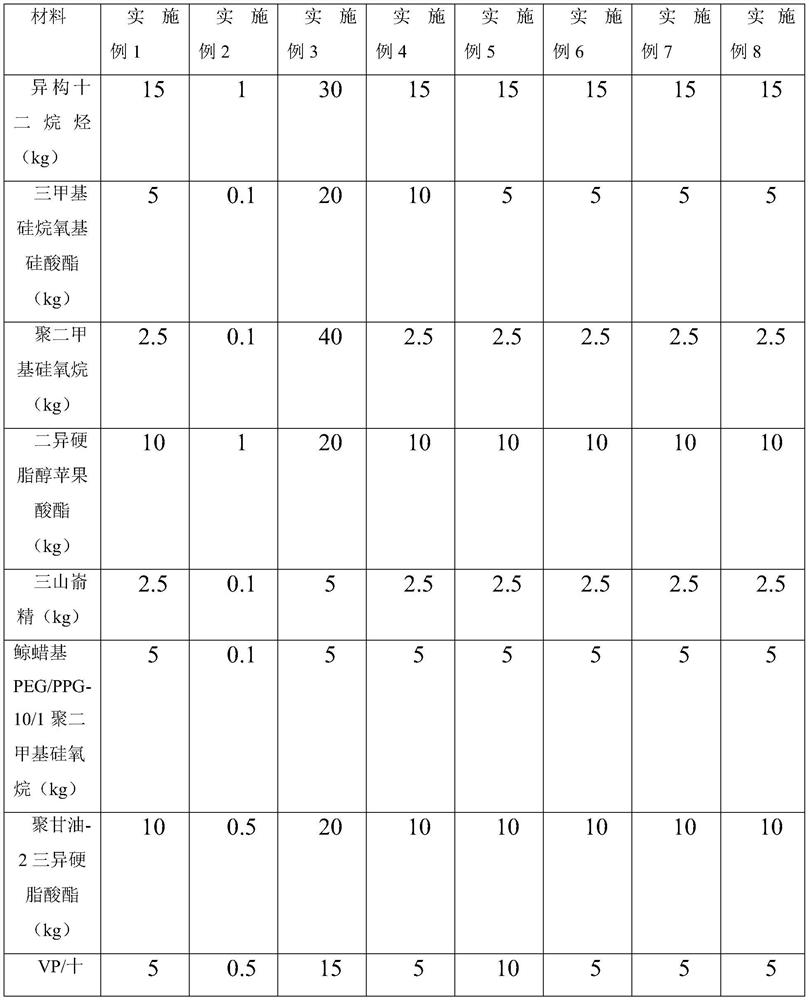

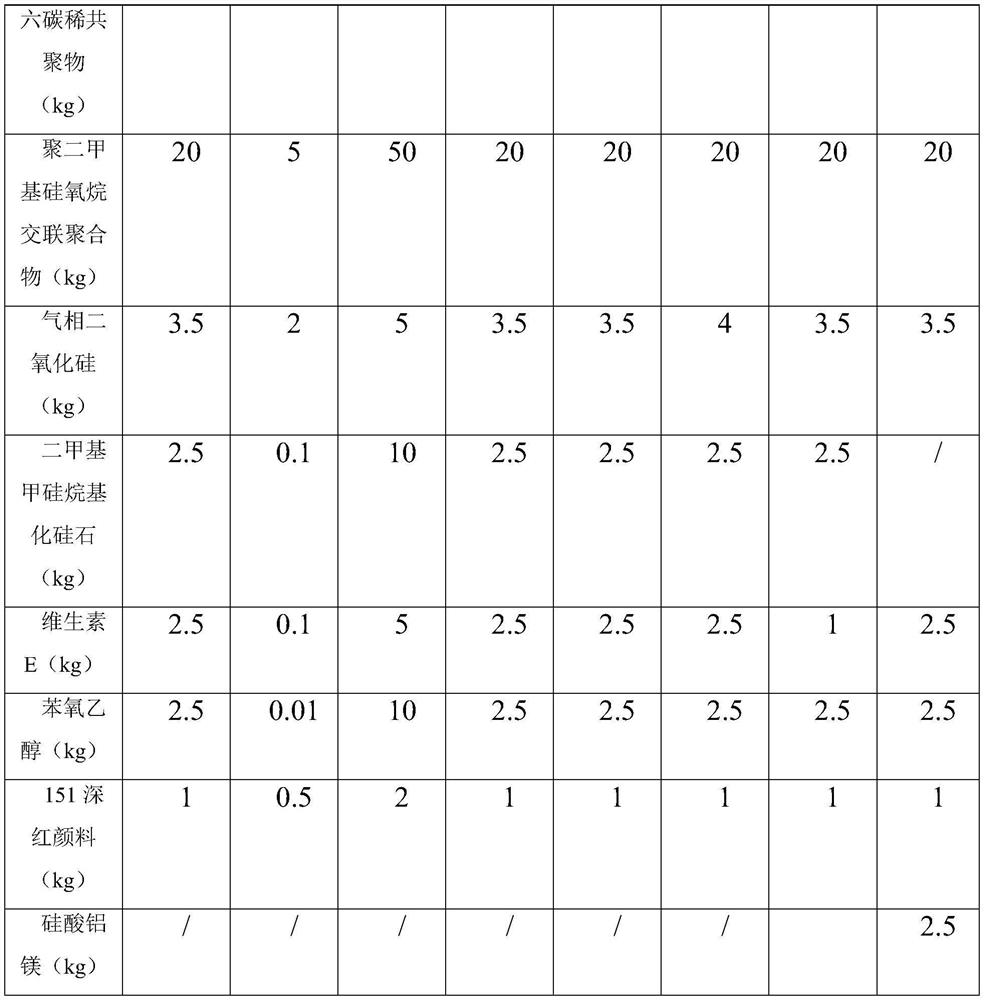

[0070] A kind of lip gloss, the raw material composition of lip gloss is as shown in table 1.

[0071] The vegetation method of above-mentioned embodiment 1, comprises following operation steps:

[0072] (1) Weigh isomeric dodecane and trimethylsiloxysilicate according to Table 1;

[0073] (2) Mix the isomeric dodecane and trimethylsiloxysilicate at 25°C, and use the emulsifying and dispersing machine produced by Xinghang Environmental Protection Machinery Technology Co., Ltd. under the working condition of 150r / min Stir for 5min to obtain mixture 1;

[0074] (3) Weigh and weigh polydimethylsiloxane, diisostearyl malate, tribehenin, cetyl PEG / PPG-10 / 1 polydimethylsiloxane and polydimethylsiloxane according to Table 1. Glyceryl-2 Triisostearate, VP / Hexadecene Copolymer, Dimethicone Crosspolymer, Fumed Silica, and Silica Dimethylsilylate;

[0075] (4) Polydimethylsiloxane, diisostearyl malate, tribehenin, cetyl PEG / PPG-10 / 1 polydimethylsiloxane and polydimethylsiloxane weighe...

Embodiment 2

[0080] A lip gloss, the difference from Example 1 lies in that: the amount of raw materials of the lip gloss is different, as shown in Table 1; and the grinding times are different in the preparation process.

[0081] The vegetation method of above-mentioned embodiment 2, comprises following operation steps:

[0082] (1) Weigh isomeric dodecane and trimethylsiloxysilicate according to Table 1;

[0083] (2) Mix the isomeric dodecane and trimethylsiloxysilicate at 25°C, and use the emulsifying and dispersing machine produced by Xinghang Environmental Protection Machinery Technology Co., Ltd. under the working condition of 150r / min Stir for 5min to obtain mixture 1;

[0084] (3) Weigh and weigh polydimethylsiloxane, diisostearyl malate, tribehenin, cetyl PEG / PPG-10 / 1 polydimethylsiloxane and polydimethylsiloxane according to Table 1. Glyceryl-2 Triisostearate, VP / Hexadecene Copolymer, Dimethicone Crosspolymer, Fumed Silica, and Silica Dimethylsilylate;

[0085] (4) Polydimethy...

Embodiment 3

[0090] A lip glaze, the difference from Example 1 is that the amount of raw materials of the lip glaze is different, as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com