Rear denitrification filter tank

A post-denitrification and denitrification technology, which is applied in anaerobic digestion treatment, chemical instruments and methods, special compound water treatment, etc. Achieve the effect of avoiding the increase of dissolved oxygen, reducing the dosage of carbon source, and high volume load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0028] In conjunction with the accompanying drawings.

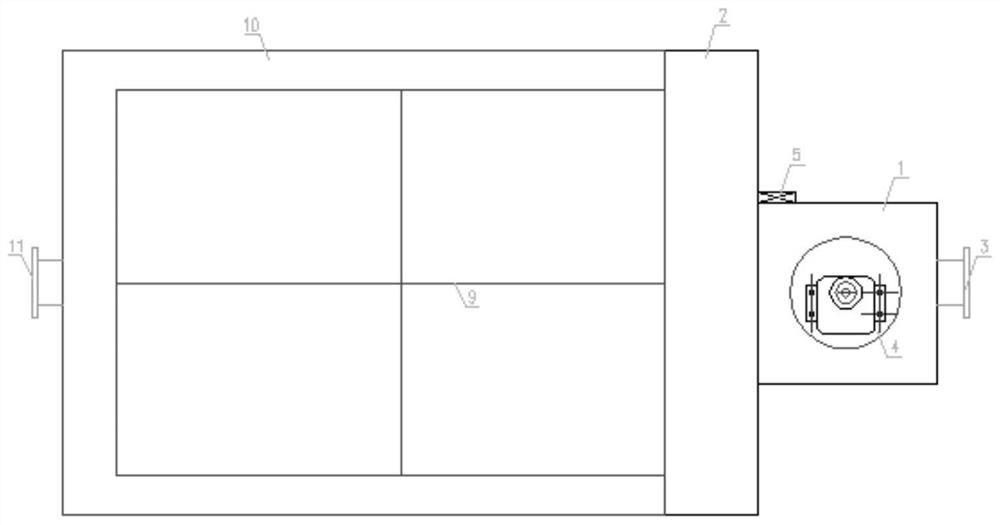

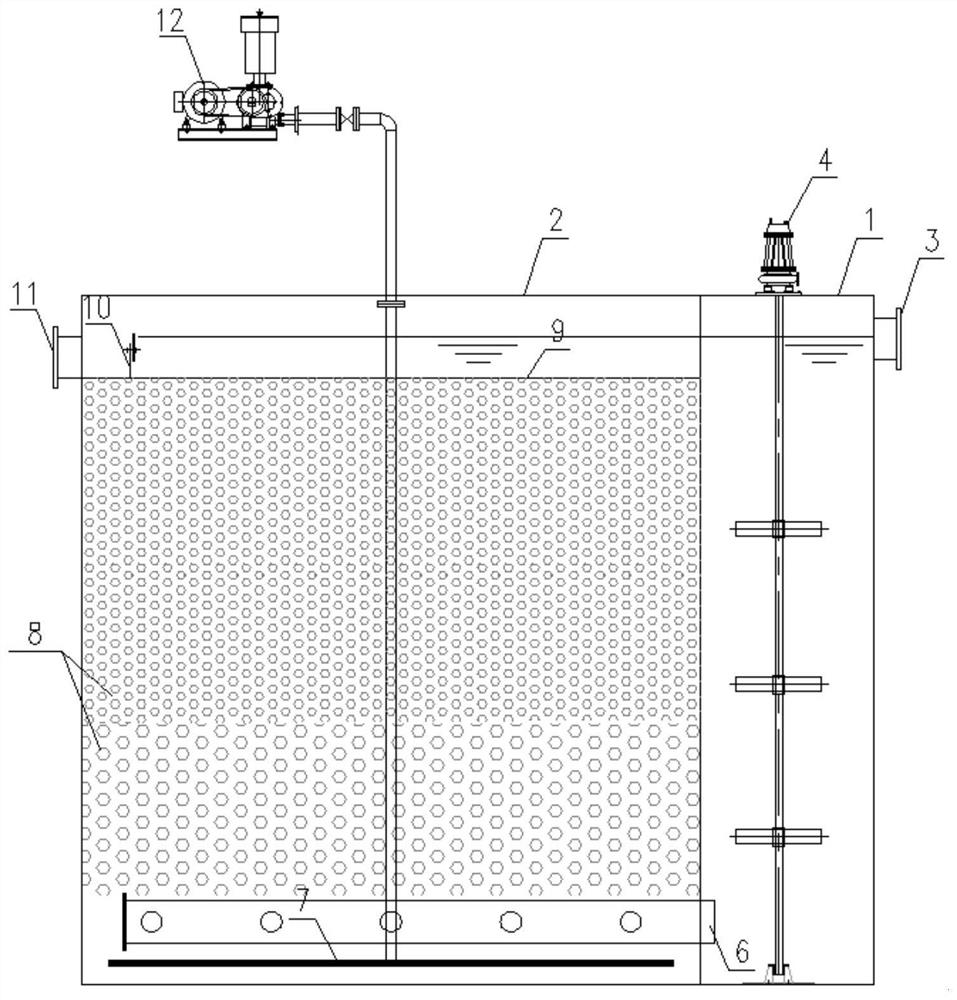

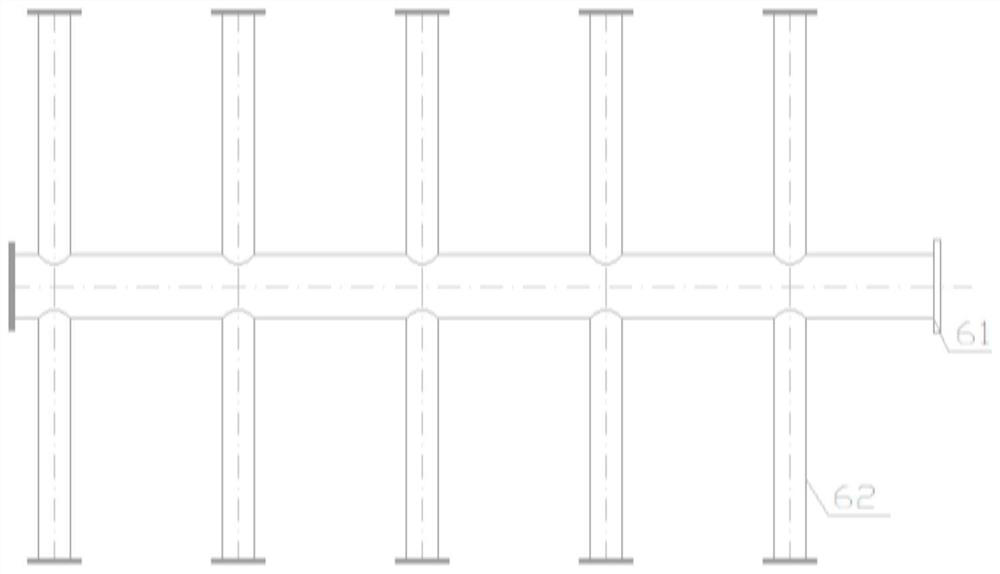

[0029] The post denitrification filter of the present invention is usually located at the rear end of the secondary sedimentation tank and the front end of the high-efficiency sedimentation tank, and the post denitrification filter includes a carbon source mixing reaction zone 1 and a nitrification reaction zone 2 . The effluent from the secondary sedimentation tank enters the carbon source mixing reaction zone 1 through the water inlet pipe 3, and the carbon source is added in this zone, and the sewage and the carbon source are fully mixed under the ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com