Solid needle type water storage device

A water storage and needle-type technology, which is applied to the surface coating liquid device, electrolytic coating, electrophoretic plating, etc., can solve the problem of destroying the surface quality of electrophoresis or baking paint, so as to help water storage and improve surface roughness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

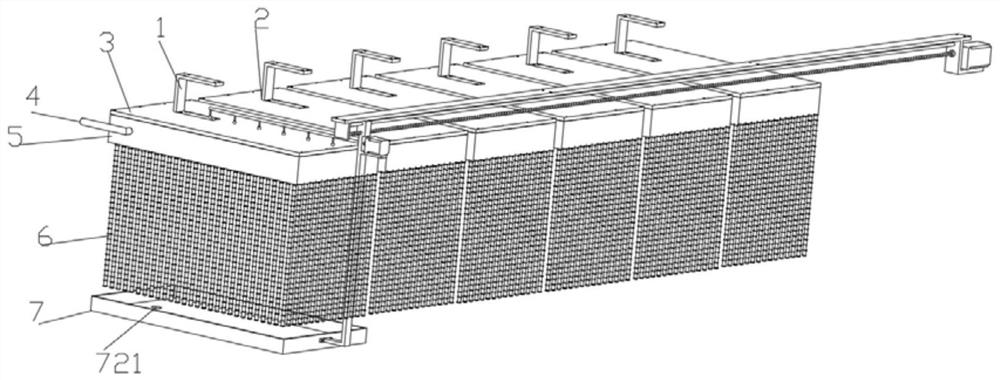

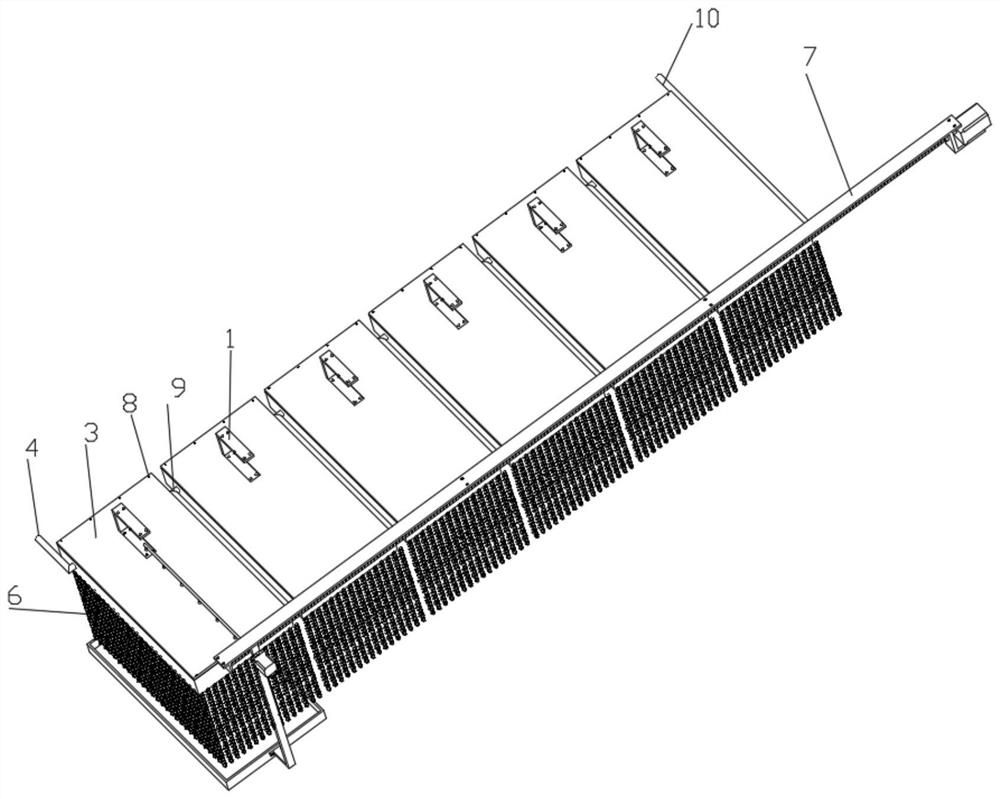

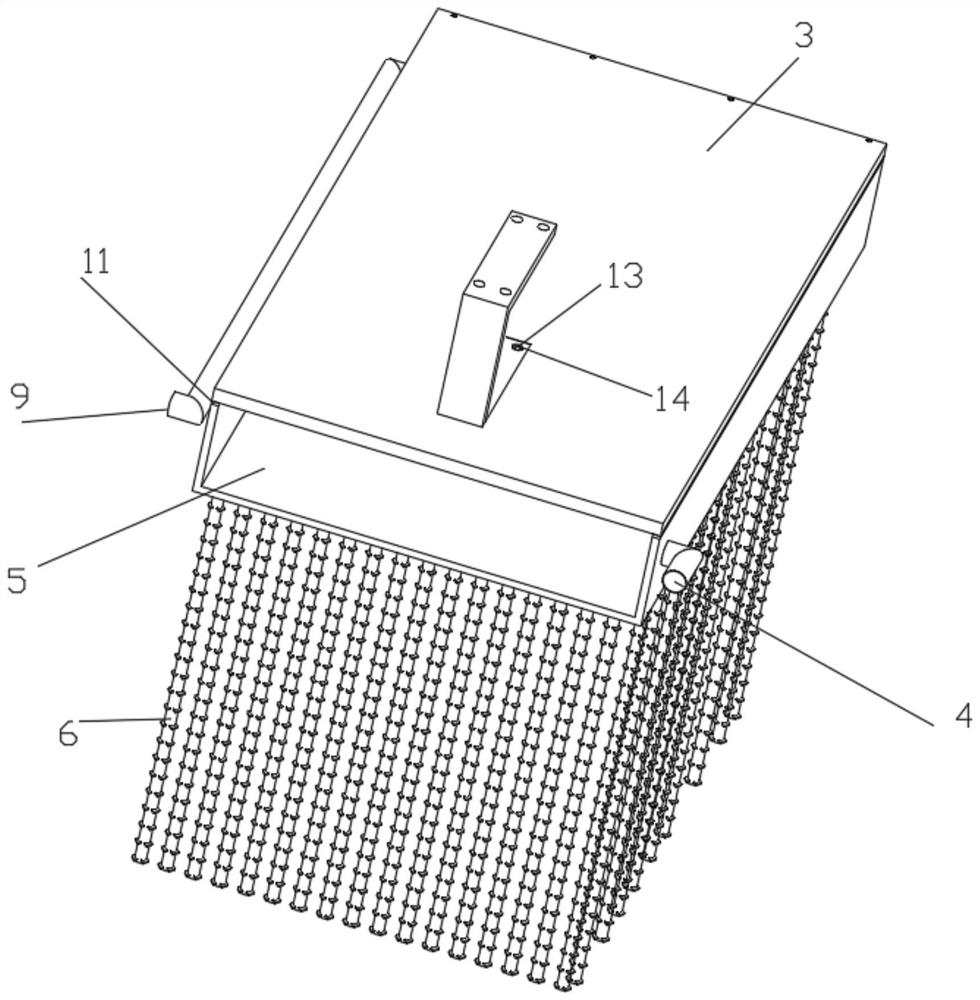

[0032] Such as Figure 1-6A solid needle-type water storage device is shown, including a C-shaped mounting frame 1 and a drainage structure 7. The bottom lateral part of the C-shaped mounting frame 1 is provided with a mounting hole 14, and the mounting hole 14 is rotatably connected with a third fixing hole. Bolt 13, the bottom of the third fixing bolt 13 is threadedly connected with the cover plate 3, the top of the cover plate 3 is provided with a straight groove 2, the bottom of the C-shaped mounting frame 1 is installed in the straight groove 2, and the bottom of the third fixing bolt 13 is connected with the straight groove 2. The bottom of the groove 2 is threaded, the bottom of the cover plate 3 is connected with a cooling structure, and the matrix at the bottom of the cooling structure is evenly fixed and connected with a fixed pin 6. The fixed pin 6 is made of a light-weight aluminum alloy with thermal conductivity, and the diameter of the fixed pin 6 is less than It...

Embodiment 2

[0034] Embodiment 2 is a further improvement to Embodiment 1.

[0035] Such as Figure 1-6 A solid needle-type water storage device shown includes a C-shaped mounting frame 1 and a drain structure 7. The bottom lateral part of the C-shaped mounting frame 1 is provided with a mounting hole 14, and a third mounting hole 14 is rotatably connected to it. Fixing bolts 13, the bottom of the third fixing bolt 13 is threadedly connected with a cover plate 3, the bottom of the cover plate 3 is connected with a cooling structure, the matrix at the bottom of the cooling structure is evenly fixed and connected with fixing pins 6, and the right end of the C-shaped mounting frame 1 is set on the right side. There is a drainage structure 7 for fixing the needle 6 to receive water. The drainage structure 7 includes a knocking structure, a first straight plate 74, a top plate 75, a sliding plate 76, a support rod 77, a first bearing 78, a first drive motor 79, a first An L-shaped plate 710, a...

Embodiment 3

[0037] Embodiment 3 is a further improvement to Embodiment 1.

[0038] Such as Figure 1-6 A solid needle-type water storage device shown includes a C-shaped mounting frame 1 and a drain structure 7. The bottom lateral part of the C-shaped mounting frame 1 is provided with a mounting hole 14, and a third mounting hole 14 is rotatably connected to it. Fixing bolts 13, the bottom of the third fixing bolt 13 is threadedly connected with a cover plate 3, the bottom of the cover plate 3 is connected with a cooling structure, the cooling structure includes an outlet pipe 4, a water tank 5, a second fixing bolt 8, an intermediate pipe 9, and a water inlet pipe 10 and gasket 11, the top of the water tank 5 is fixedly connected with a gasket 11, the water tank 5 is connected to the cover plate 3 through the gasket 11, and the water tank 5 and the cover plate 3 are threadedly connected with a second fixing bolt 8 through a threaded hole. Adjacent water tanks 5 are fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com