Rapid forming device and system for ultra-high molecular weight polymer and control method of rapid forming system

An ultra-high molecular weight, molding device technology, applied in manufacturing auxiliary devices, additive manufacturing, manufacturing tools, etc., can solve the problems of relatively strict environmental temperature requirements, affecting molding quality, and narrow processing temperature range of ultra-high molecular weight polymers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

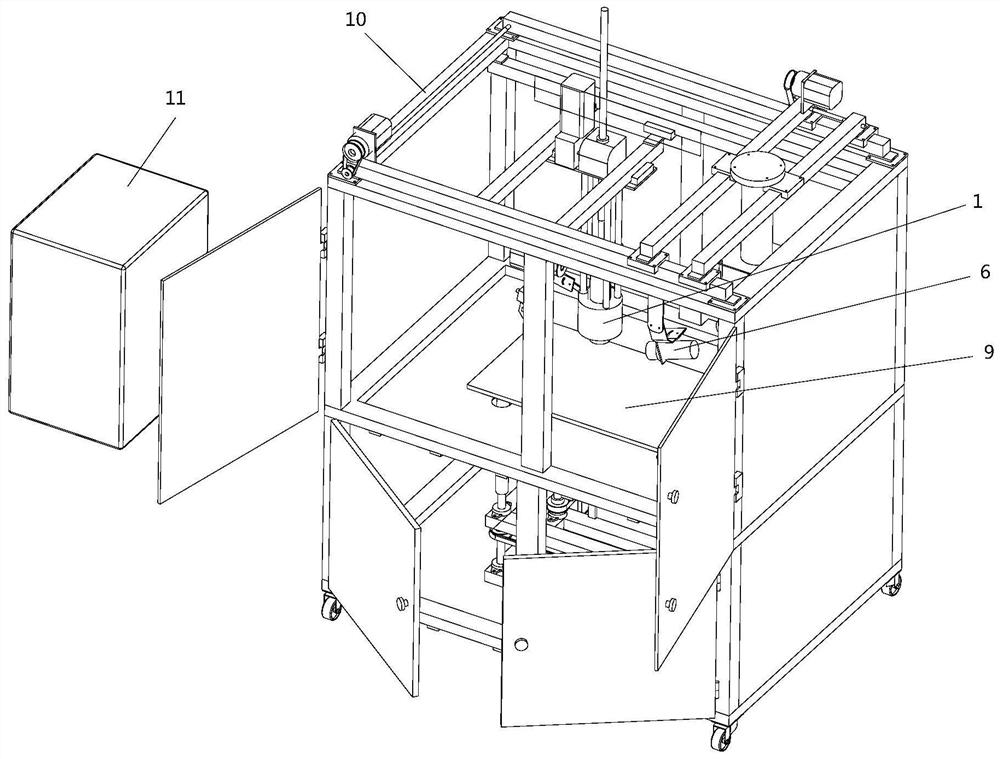

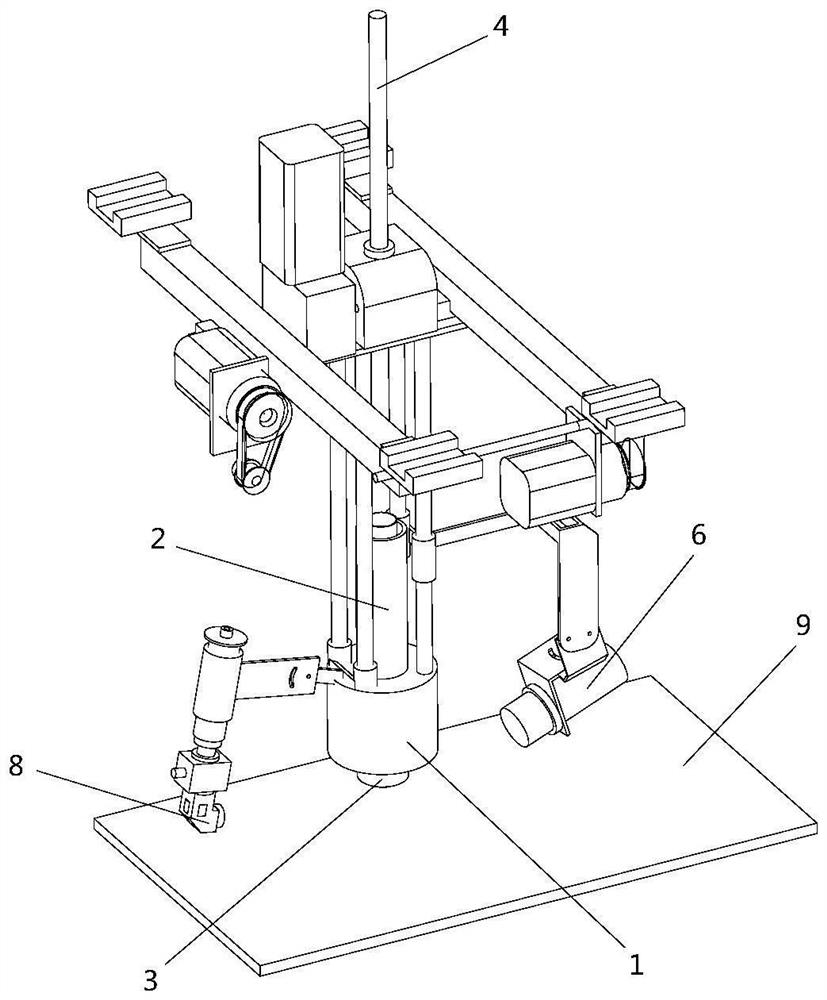

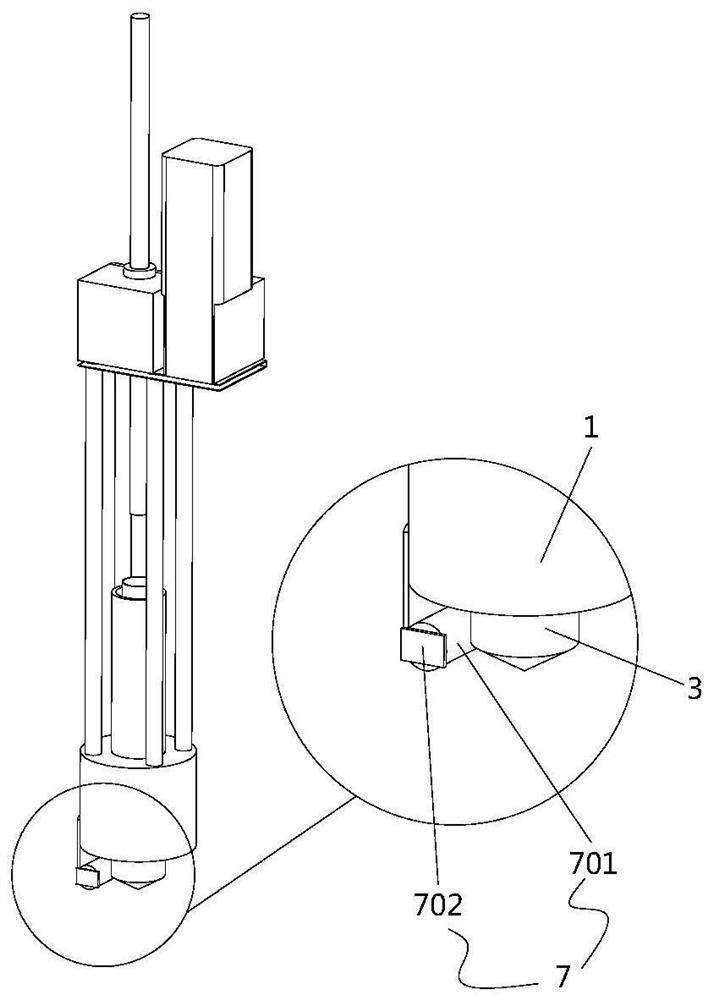

[0120] Such as Figure 1 to Figure 5 As shown, a rapid prototyping device 1 for ultra-high molecular weight polymers described in this embodiment includes a silo 2, and a chamber for holding ultra-high molecular weight polymers is arranged inside; a nozzle 3 is arranged on the material The bottom of the bin 2; the feeding rod 4 is set to be able to extend into or out from the top of the bin 2, and is used to extrude the ultra-high molecular weight polymer in the molten state from the nozzle 3 out of the bin 2. The heating module 5 forms a heating area where the temperature gradually increases from the top of the silo 2 to the side of the spray head 3 at the bottom.

[0121] Wherein, the heating area is sequentially divided into a first heating area 501, a second heating area 502 and a third heating area 503 from the top of the silo 2 to the bottom side; The ultra-high molecular weight polymer is in the original state when it is put into the silo 2; the ultra-high molecular we...

Embodiment 2

[0123] Such as Figure 1 to Figure 5 As shown, this embodiment is based on the above-mentioned embodiment 1. In the rapid prototyping device 1 for ultra-high molecular weight polymers described in this embodiment, the heating range of the first heating zone 501 is the same as that of the second heating zone 501. The ratio of the heating range sum of the heating zone 502 and the third heating zone 503 is between 1:3 and 1:1; the heating range ratio of the second heating zone 502 and the third heating zone 503 is between Between 1:5 and 1:1.

Embodiment 3

[0125] Such as Figure 1 to Figure 5 As shown, this embodiment is based on the above-mentioned embodiment 1 or embodiment 2. The heating module 5 in this embodiment is a heating wire that cooperates with the silo 2; the heating temperature of the heating module 5 is from 100°C to Between 450°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com