Preparation method and use method of quick-dissolving lime for converter slag

A converter slag and lime technology, which is applied in the field of quick-dissolving lime preparation for converter slag, can solve problems such as co-solvent environmental pollution and increase steelmaking costs, and achieve the effects of accelerated dissolution, fast dissolution rate, and small grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

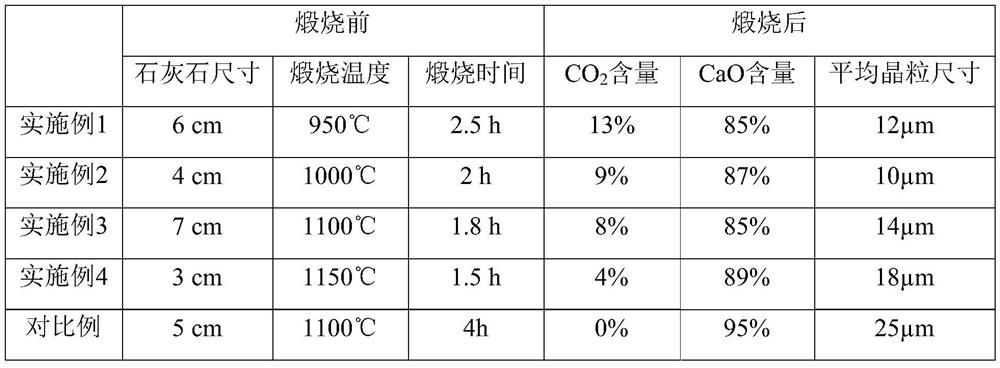

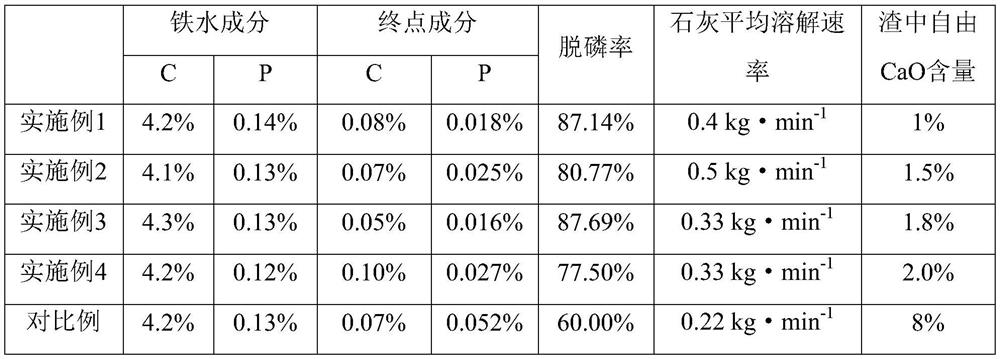

[0025] A kind of converter slag of the present embodiment is used for the quick dissolving lime preparation method, in order to obtain this lime, its experimental preparation condition is carried out on the induction furnace of 200kg, and its process is: at first screening the limestone that size is 6cm, makes it in the muffle furnace For calcination, after the material is put into the muffle furnace, it is heated at a heating rate of 6-10°C / min. After the temperature of the muffle furnace reaches 950°C, the calcination temperature is controlled to be 950°C, and the calcination time is controlled to be 2.5h, which is worth It is explained that during the entire calcination process, protection is carried out under the atmosphere of argon. In addition to protection, the important role of argon is to convert the generated CO 2 The gas is discharged, so that during the calcination process CO 2 The partial pressure is always low, which is conducive to the decomposition of limestone...

Embodiment 2

[0040]A kind of method for preparing converter slag of the present embodiment with fast dissolving lime is basically the same as that of embodiment 1, and its difference is that the process is: firstly, the limestone with a size of 4 cm is screened, and it is calcined in a muffle furnace, and then heated in argon. Under the protective atmosphere of gas, the calcination temperature is controlled to be 1000°C, and the calcination time is controlled to be 2h, and then it is cooled and sealed for later use, so as to obtain the required lime.

[0041] The prepared lime was sampled and tested, and the specific parameters of the lime are shown in Table 1.

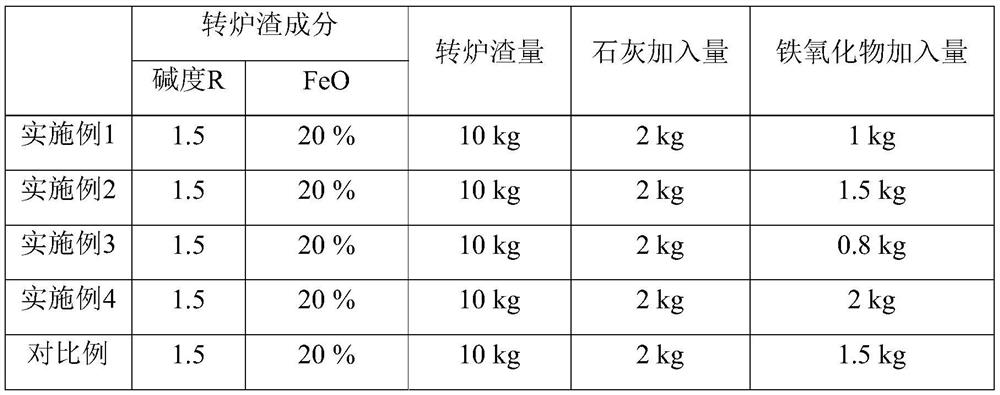

[0042] A method of quickly dissolving lime for converter slag in this embodiment, first, take 100 kg of industrial pig iron and 10 kg of converter decarburization slag on a silicon molybdenum rod and heat it to 1400 ° C to fully melt the slag, and keep it warm for 30 minutes. The relevant parameters of the converter slag are shown...

Embodiment 3

[0047] A kind of method for preparing converter slag of the present embodiment with fast dissolving lime is basically the same as in embodiment 1, and its difference is that the process is: at first screening the limestone with a size of 7 cm, making it calcined in a muffle furnace, Under the protective atmosphere of gas, the calcination temperature is controlled to be 1100°C, and the calcination time is controlled to be 1.8h, and then it is cooled and sealed for later use, so as to obtain the required lime.

[0048] The prepared lime was sampled and tested, and the specific parameters of the lime are shown in Table 1.

[0049] A method of quickly dissolving lime for converter slag in this embodiment, first, take 100 kg of industrial pig iron and 10 kg of converter decarburization slag on a silicon molybdenum rod and heat it to 1400 ° C to fully melt the slag, and keep it warm for 30 minutes. The relevant parameters of the converter slag are shown in Table 2. After being kept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com